Microwav eoven heater system

A technology for a heater and a microwave oven, applied in the field of microwave ovens, can solve the problem that the heater 7 is easily polluted by dirt, and achieve the effect of effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

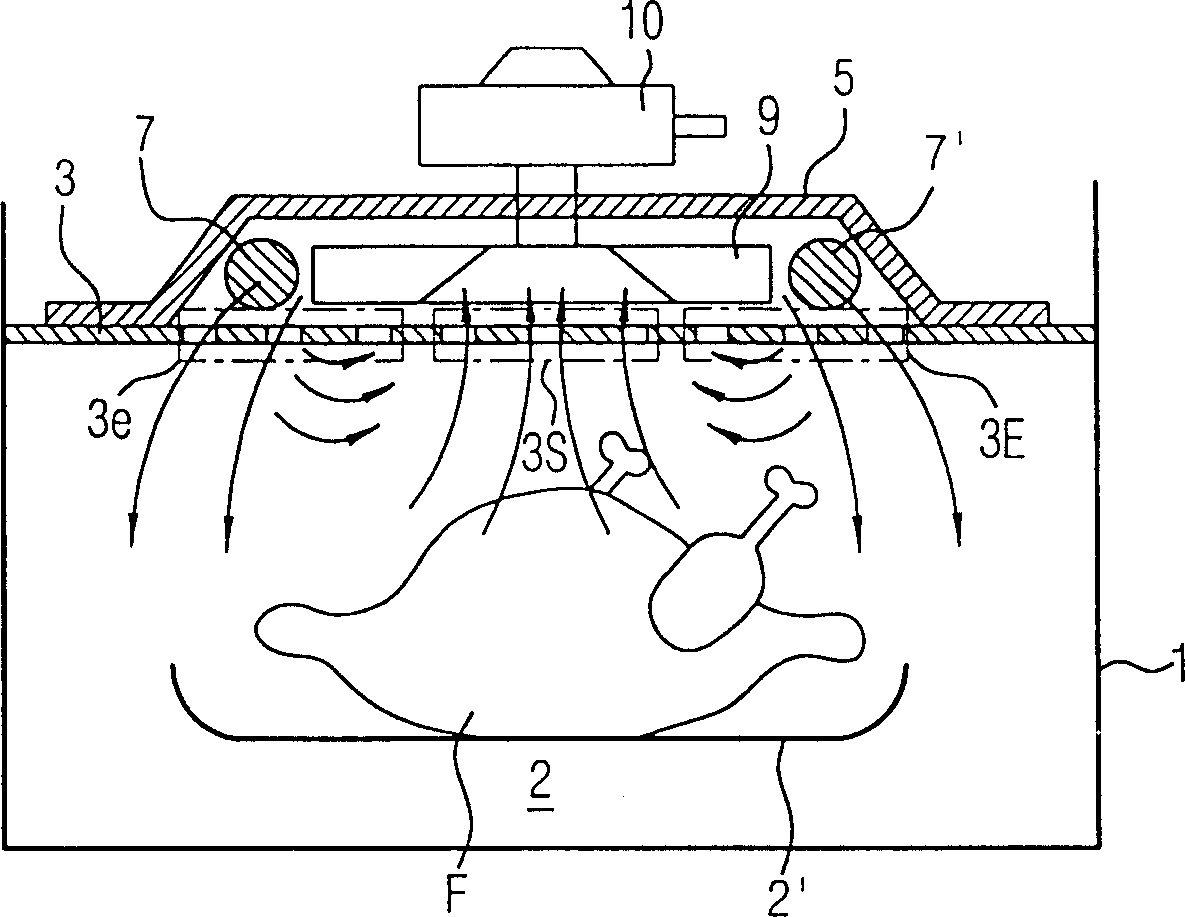

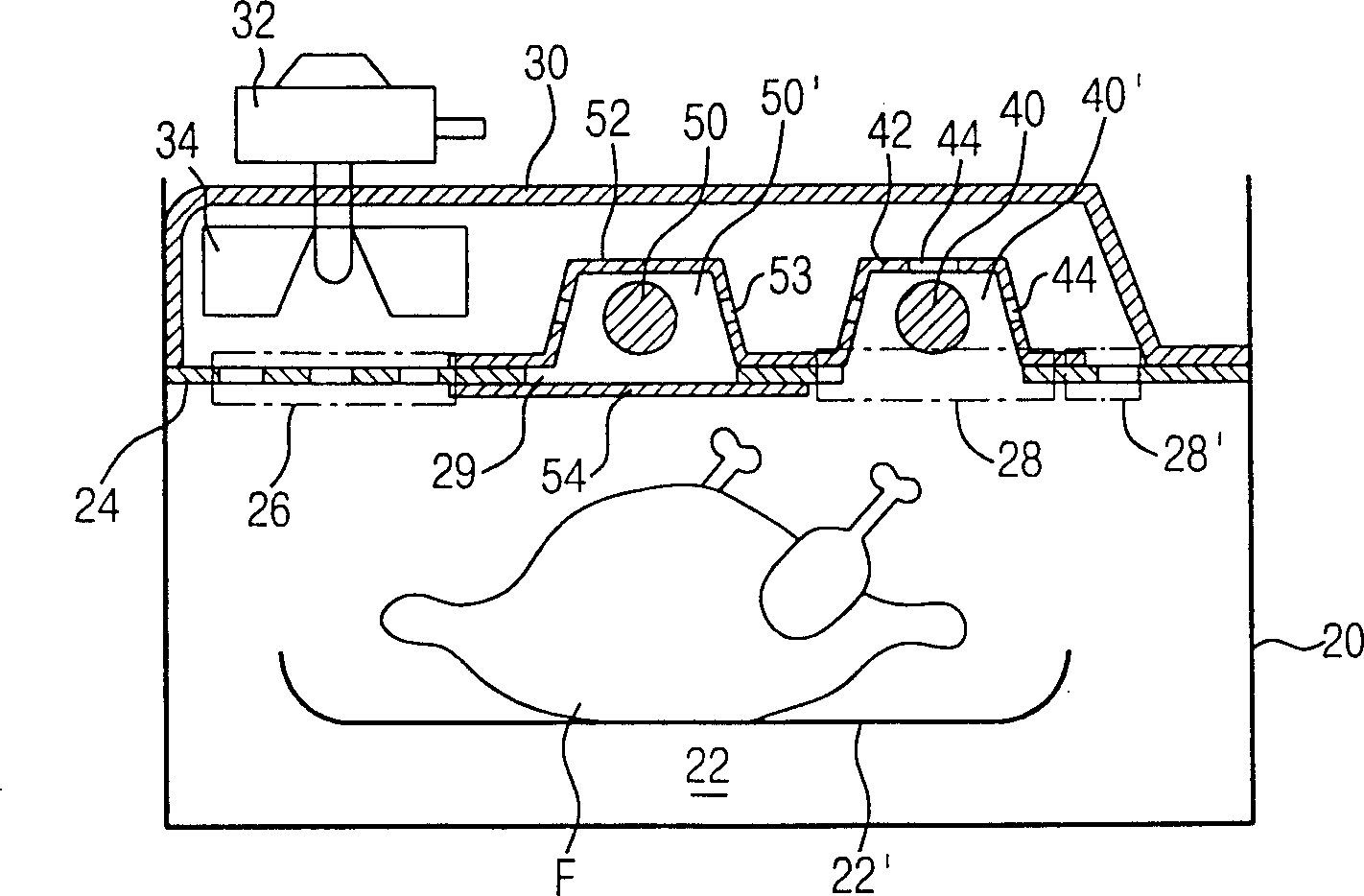

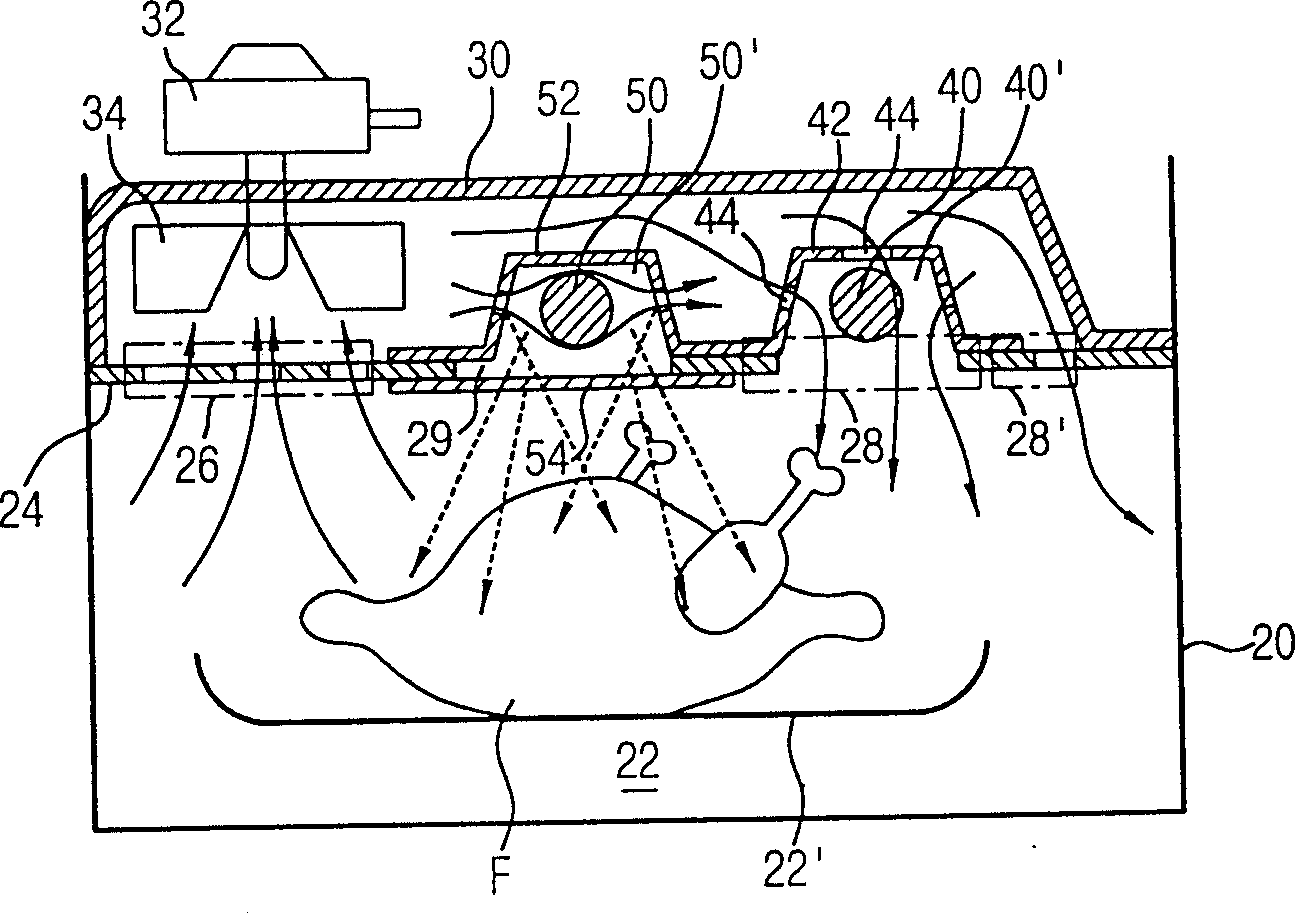

[0026] Hereinafter, the heater system of the microwave oven of the present invention will be described with reference to the accompanying drawings.

[0027] figure 2 It is a structural sectional view of the microwave oven heater system of the present invention.

[0028] Such as figure 2 As shown, a cooking chamber 22 is formed within the cavity 20 of the microwave oven. In the cooking chamber 22, cooking food F on a plate 22' is cooked by microwave energy supplied from a magnetron (not shown) mounted on an electric chamber (not shown) or heat generated by a heater system.

[0029] An upper plate 24 is formed on the upper surface of the cooking chamber 22 while the upper plate 24 constitutes the roof of the cooking chamber 22 . A suction part 26 and a discharge part 28 are respectively formed on the upper plate 24, the suction part 26 forms the airflow from the inside of the cooking chamber 22, and the discharge part 28 forms the airflow from the outside of the cooking cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com