Waterproof shoes and boots and its manufacturing method

A manufacturing method and technology for waterproof shoes, which are applied in the directions of footwear, clothing, and applications, can solve the problem of having to apply a waterproof sealing device, etc., and achieve the effect of good waterproof characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

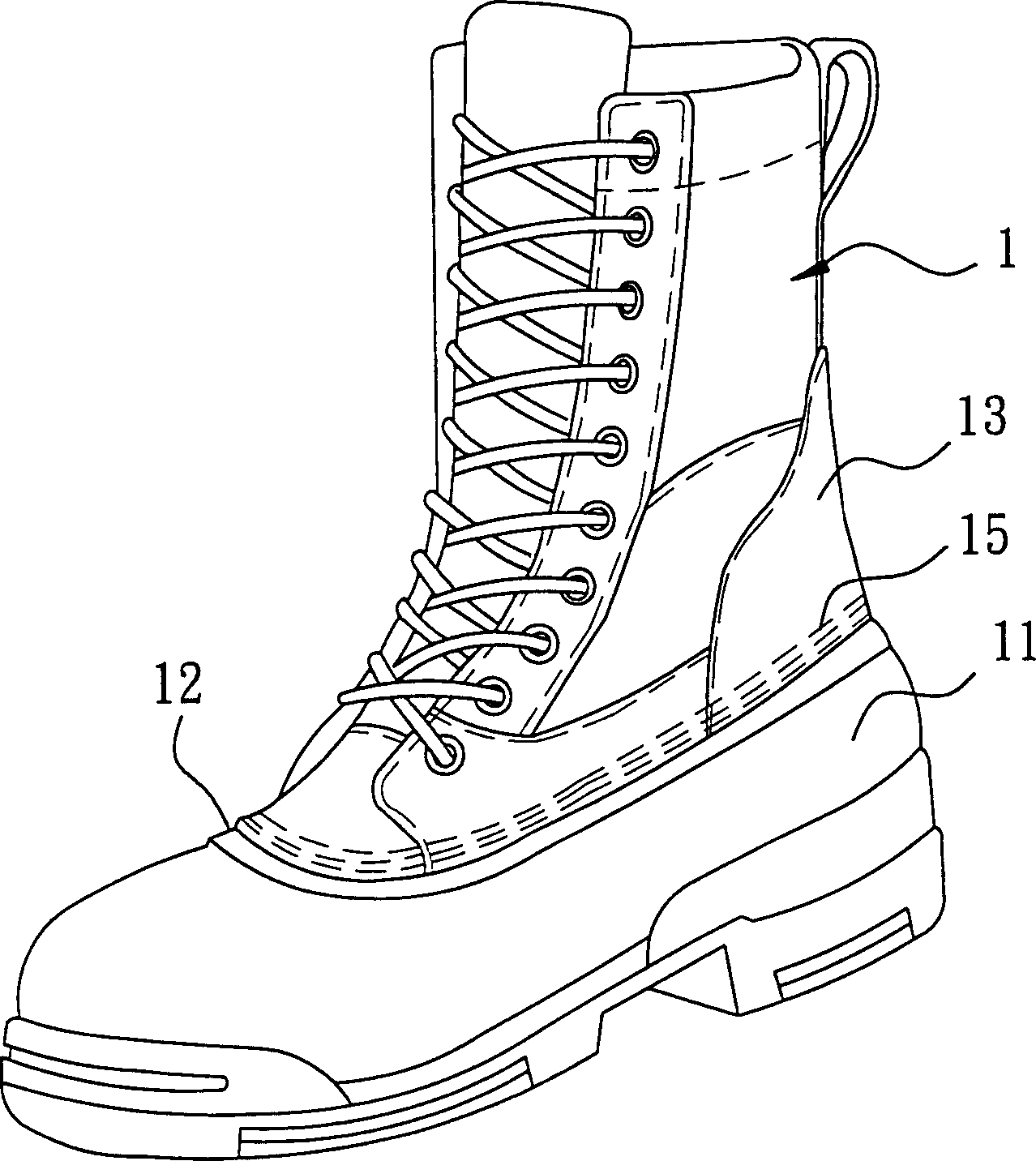

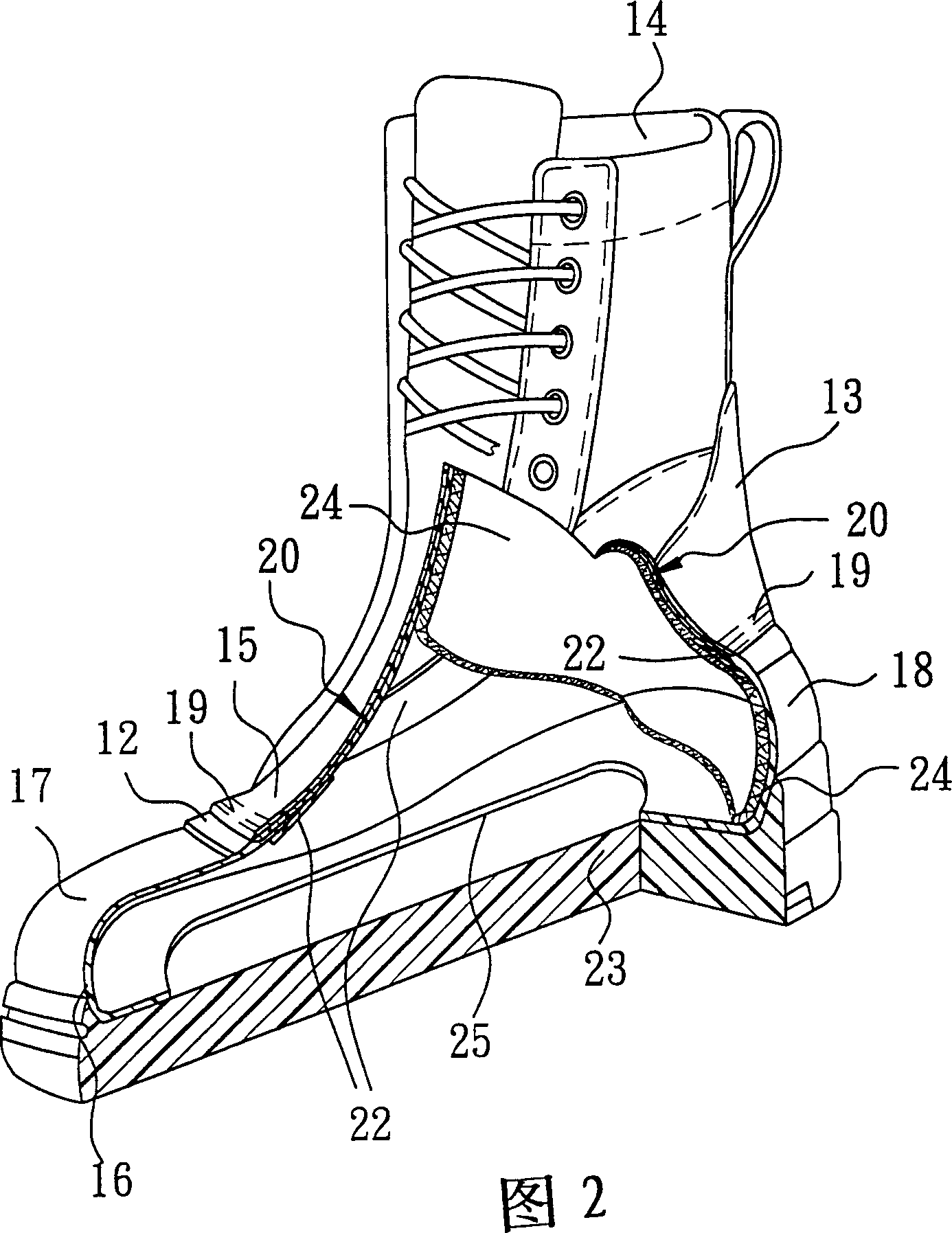

[0048] Such as figure 1 As shown in, 2 and 3, the footwear 1 of the embodiment of the present invention is shown to include an upper body 13 forming a shoe upper and a shoe cover body 11 defining a shoe cover. The upper body 13 includes an upper open end. 14 and the lower open end 15, and are formed by a plurality of cutting pieces stitched together. The shoe cover body 11 is a one-piece molded shell made of waterproof material. The shoe cover body 11 has an upper open end 12, a lower The end 16, a toe part 17 and a heel part 18. The heel part 18 is connected to the toe part 17 between the upper open end 12 and the lower end 16, and the upper open end 12 of the shoe cover body 11 is connected to The lower open end 15 of the upper body 13.

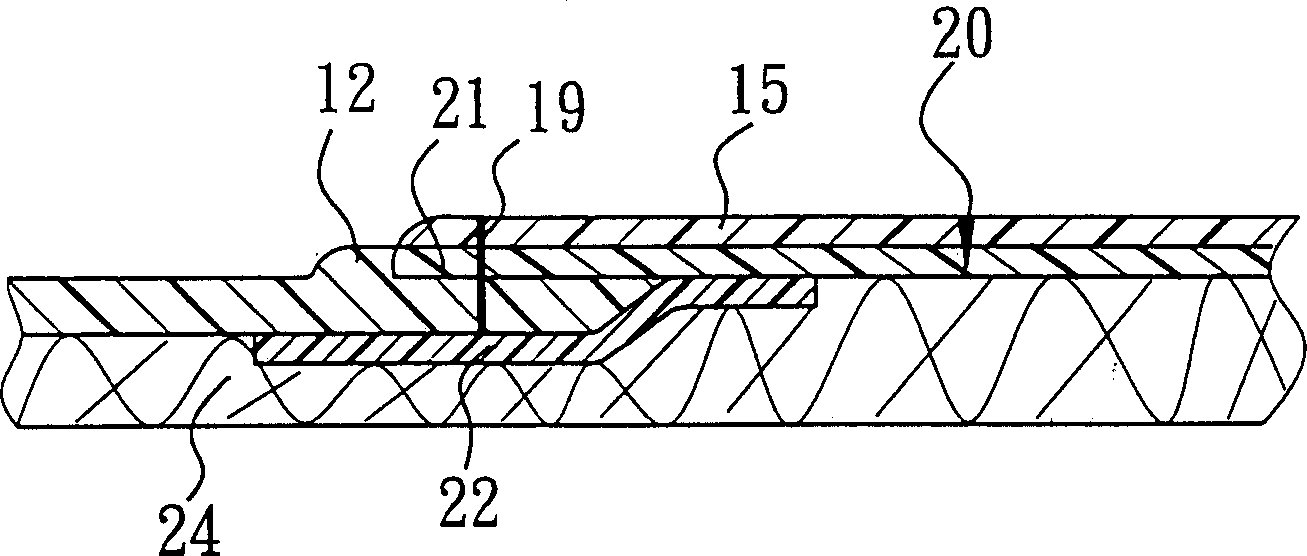

[0049]A waterproof inner sleeve 20 is provided inside the upper body 13 to serve as a lining for the upper body 13. The waterproof inner sleeve 20 has a lower open end 21 extending along the lower open end of the upper body 13, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com