Diffuser with dual-column blades arranged radially and serially

A diffuser and vane technology, which is applied in the field of radial tandem double-row vane diffusers, and can solve problems such as narrow flow cross-sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

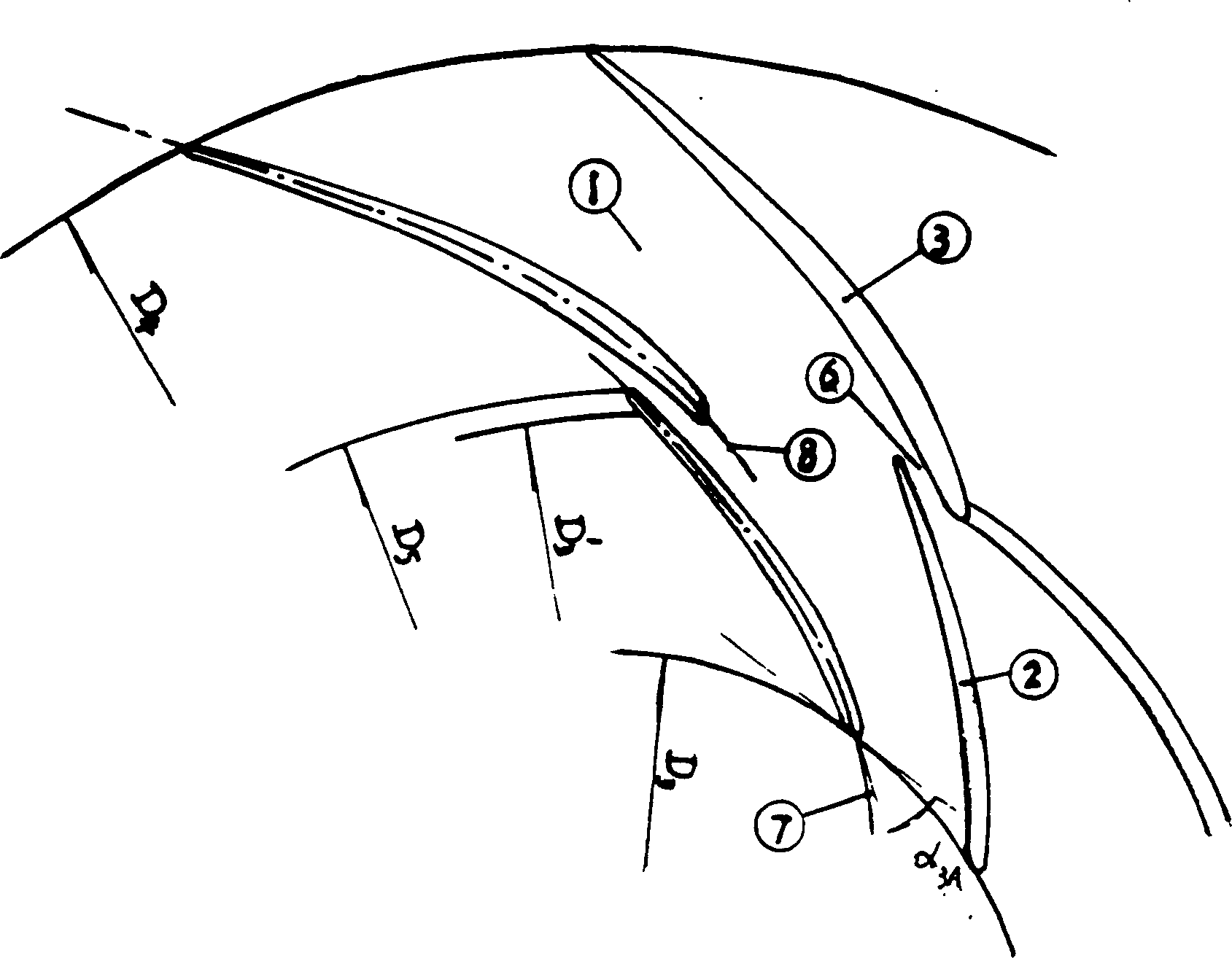

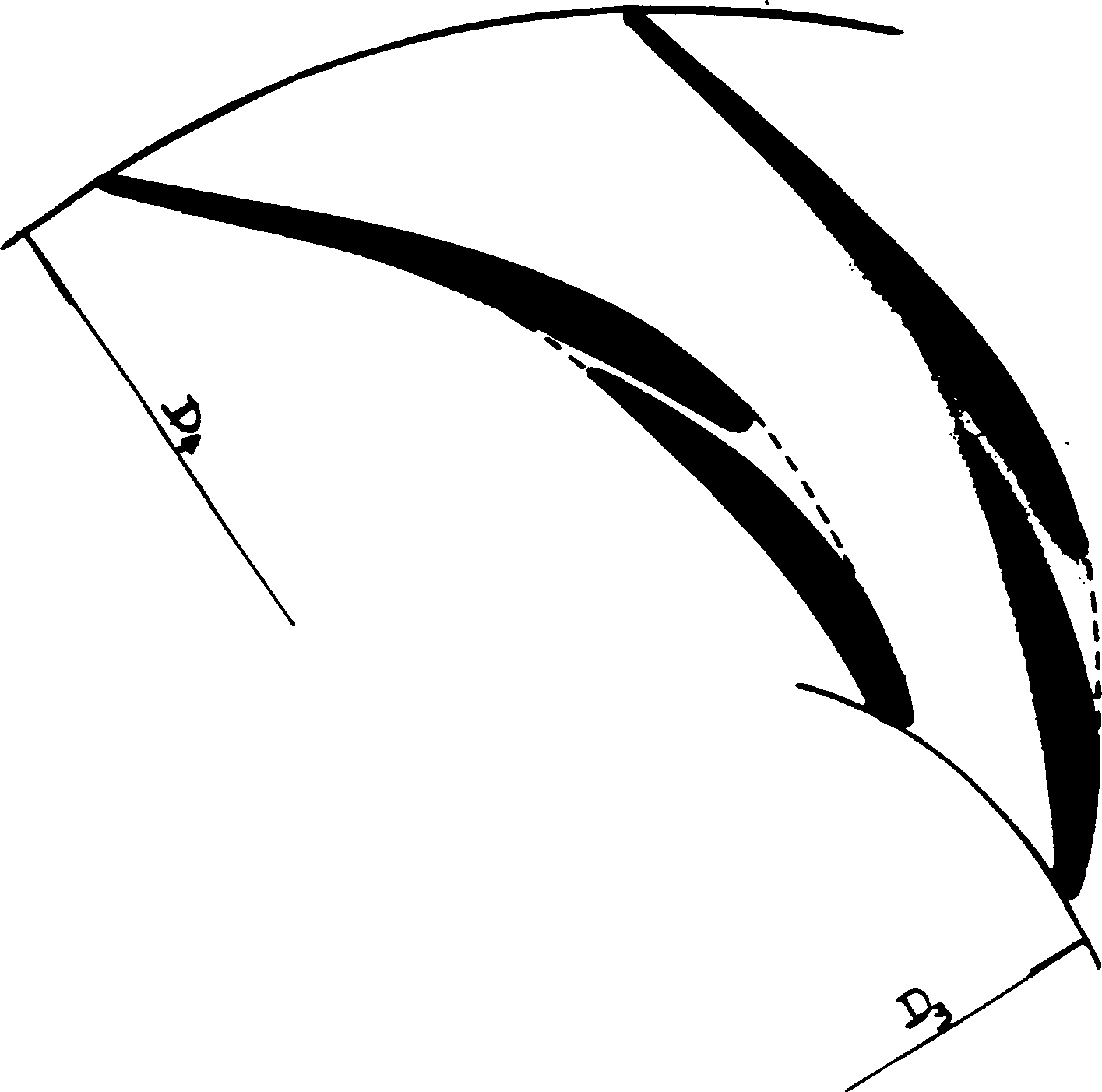

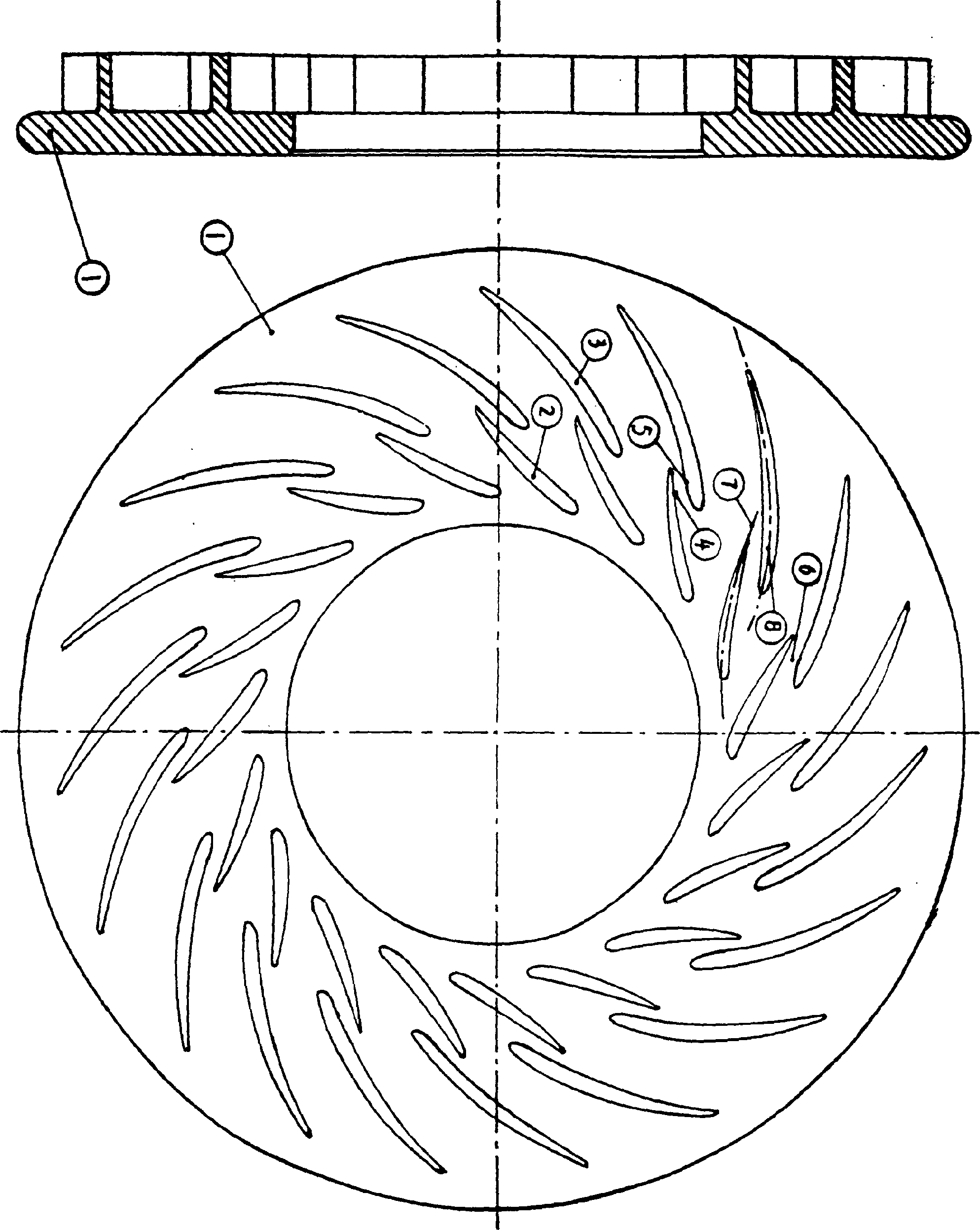

[0014] image 3 Schematic view of the structure of a radially serially arranged double-row vane diffuser constructed for the present invention. The radially arranged double-row vane diffuser is composed of three parts: an annular bottom plate ①, an annular cascade composed of vanes in the front row ②, and an annular cascade composed of blades in the rear row ③. The vanes of the front cascade ② and the rear cascade ③ are consolidated on the bottom plate ① (formed by integral precision casting or CNC milling). On the same side of the bottom plate ①, the front and rear rows of cascades ② and ③ are arranged radially in series with each other and staggered along the circumference (the diameter at the trailing edge of the blades of the front cascade ② can be greater than or equal to or smaller than that of the rear cascade ③ diameter of the blade inlet leading edge). The curved concave-convex direction of the middle arc ⑧ of the rear row of blades is the same as the curved concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com