Dual-column adjustable circular cone roller main bearing

A technology of tapered roller bearings and tapered rollers, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problem of disproportionate front and rear loads of main bearings of horizontal lathes, small radial clearance adjustments, and long service life Short and other problems, to achieve the effect of simple structure, less maintenance, long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

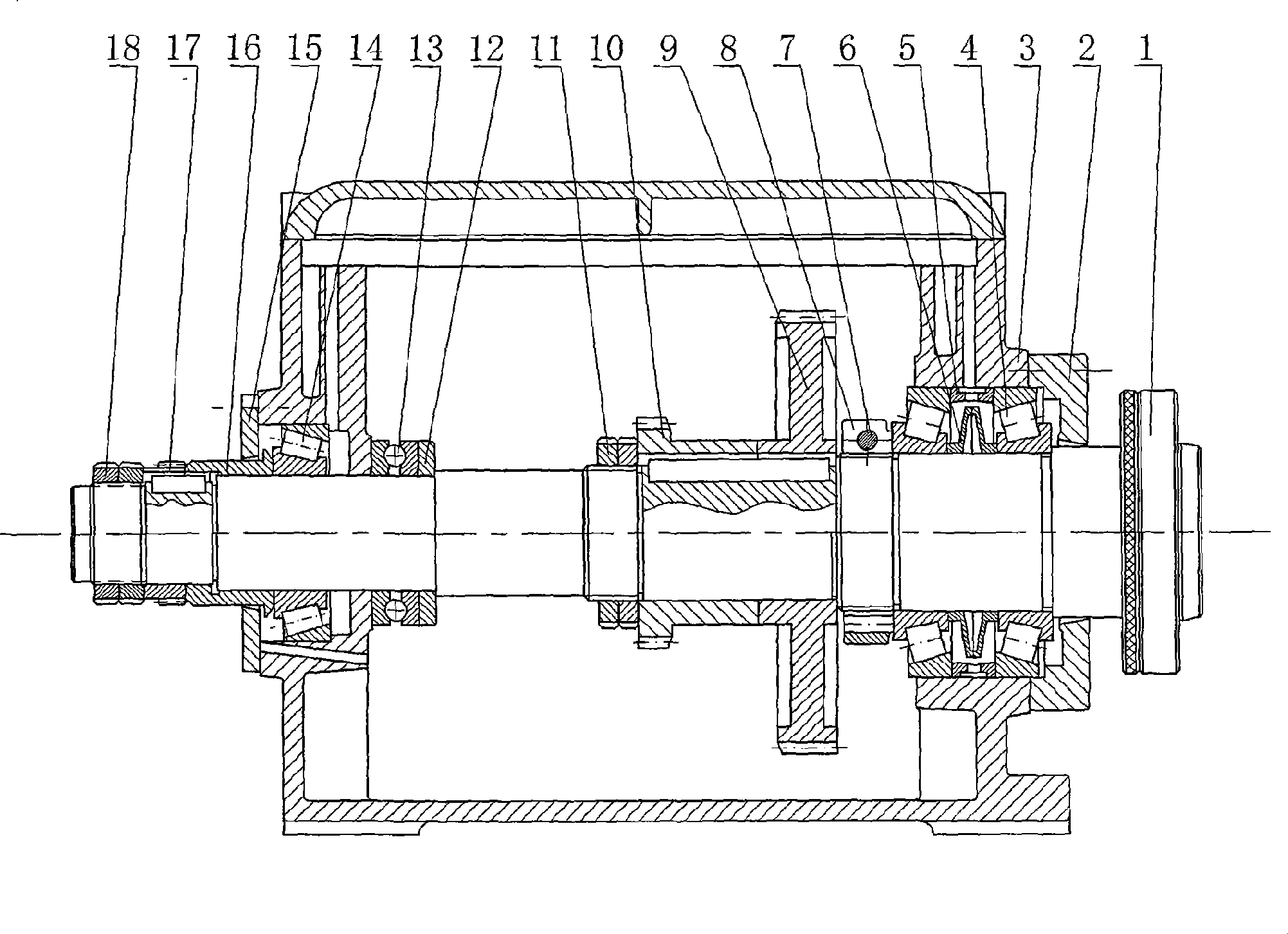

[0010] The present invention is arranged in the headstock of horizontal lathe (as shown in the figure), in the main shaft 1 and the main shaft 3, be provided with (main shaft 1) front bearing cover 2, (headstock 3), tapered roller bearing 4, interval Set 5, special disc spring 6, locking screw 7, special round nut 8, low speed large gear 9, high speed pinion 10, round nut 11, washer 12, thrust bearing 13, tapered roller bearing 14, rear cover 15, block sleeve 16, pinion 17, round nut 18 etc. are formed. A pair of special disc springs 7 will have a certain preload when assembling to ensure the stability and reliability in use. This structure is also applicable to multi-row angular contact ball bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com