Square work outer-lane dual-column cylindricl roller bearing for precision punching

A cylindrical roller bearing, precision punching technology, applied in the field of bearings, to achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

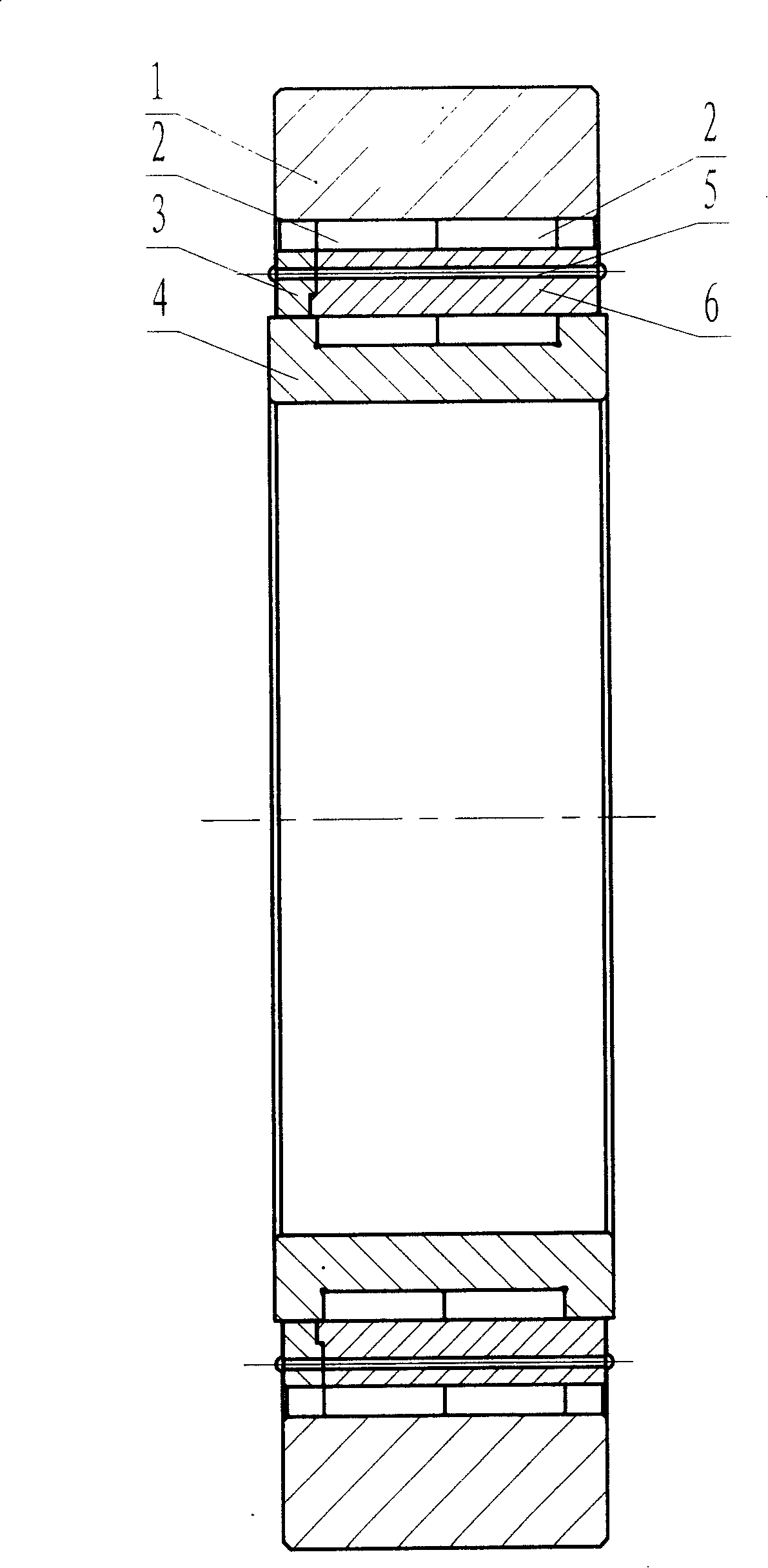

[0012] Such as figure 1 Shown: the double-row cylindrical roller bearing with square working outer ring for precision punching machine of the present invention, the outer ring (1) of its bearing is a square thick-walled structure, the inner ring (4) is a circular structure, and the width of the inner ring (4) is Larger than the width of the outer ring (1), two rows of cylindrical rollers (2) are arranged side by side in the raceway set by the inner and outer rings, and the two rows of cylindrical rollers (2) are placed in the pockets of the cage (6) , and a cage end cover (3) is arranged at one end of the cage (6), which is riveted together by rivets (5).

[0013] The bearing outer ring (1) of the present invention is designed as a square thick-walled structure. When the four cuboid surfaces are working, two of the adjacent surfaces directly bear the load, and the other two adjacent surfaces are not stressed. When the adjacent surface is worn, it can be replaced by two unstre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com