Three-axis pivot structure

A three-axis, pivotal technology, applied in the direction of instruments, electrical digital data processing, calculation, etc., can solve the problems of unstable center of gravity, inconvenient operation, cost increase, etc., and achieve the effect of increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

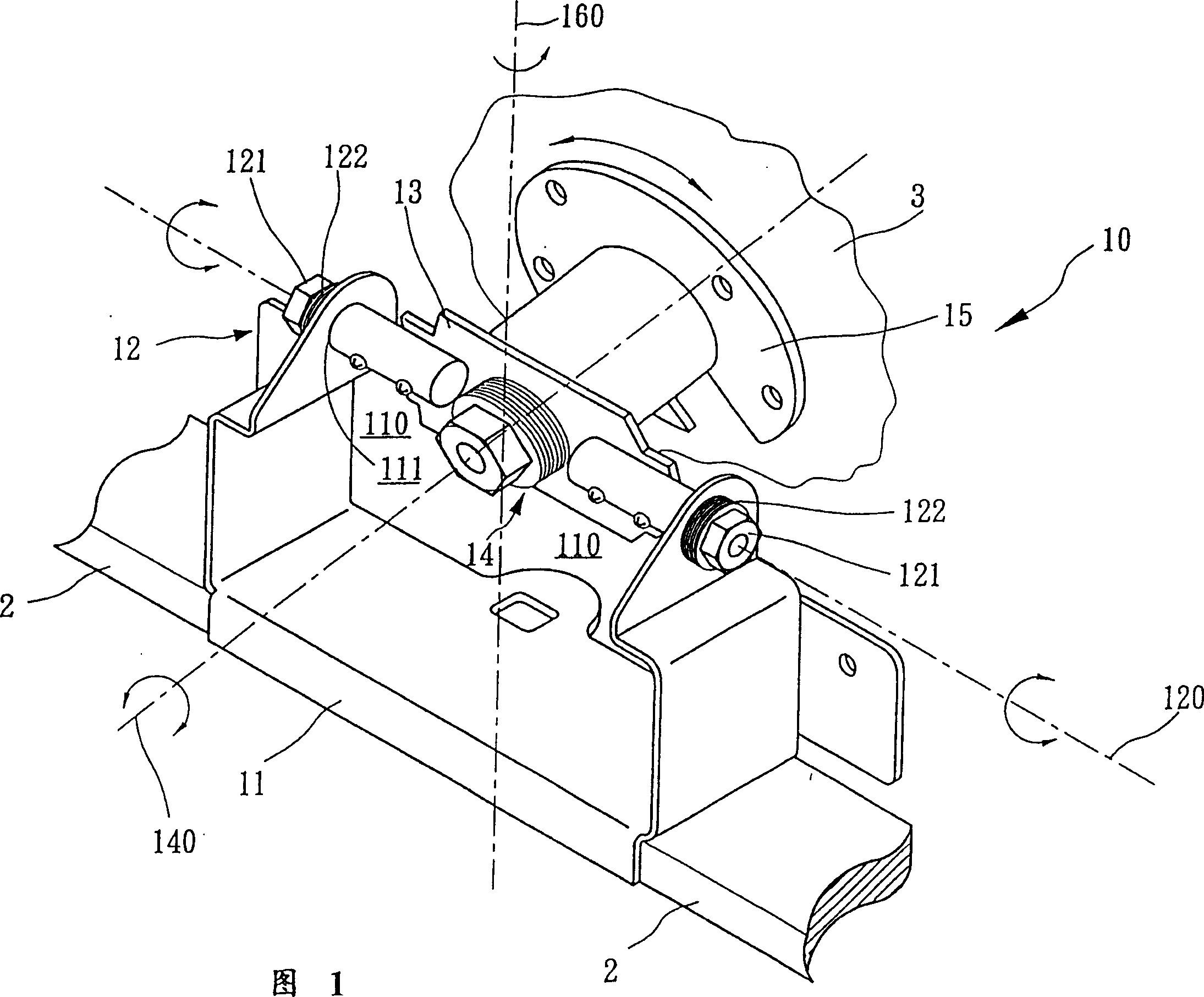

[0022] The three-axis pivot structure of the present invention is applied to an LCD panel combined with a computer or other objects, and the LCD panel is fixed on a base, using the three rotation directions provided by the three-axis pivot structure , so that the three-way rotation is performed between the LCD panel and the base, and the pivot structure can also be supported on the center of gravity of the LCD panel, so it has the functions of reducing shaking and increasing stability.

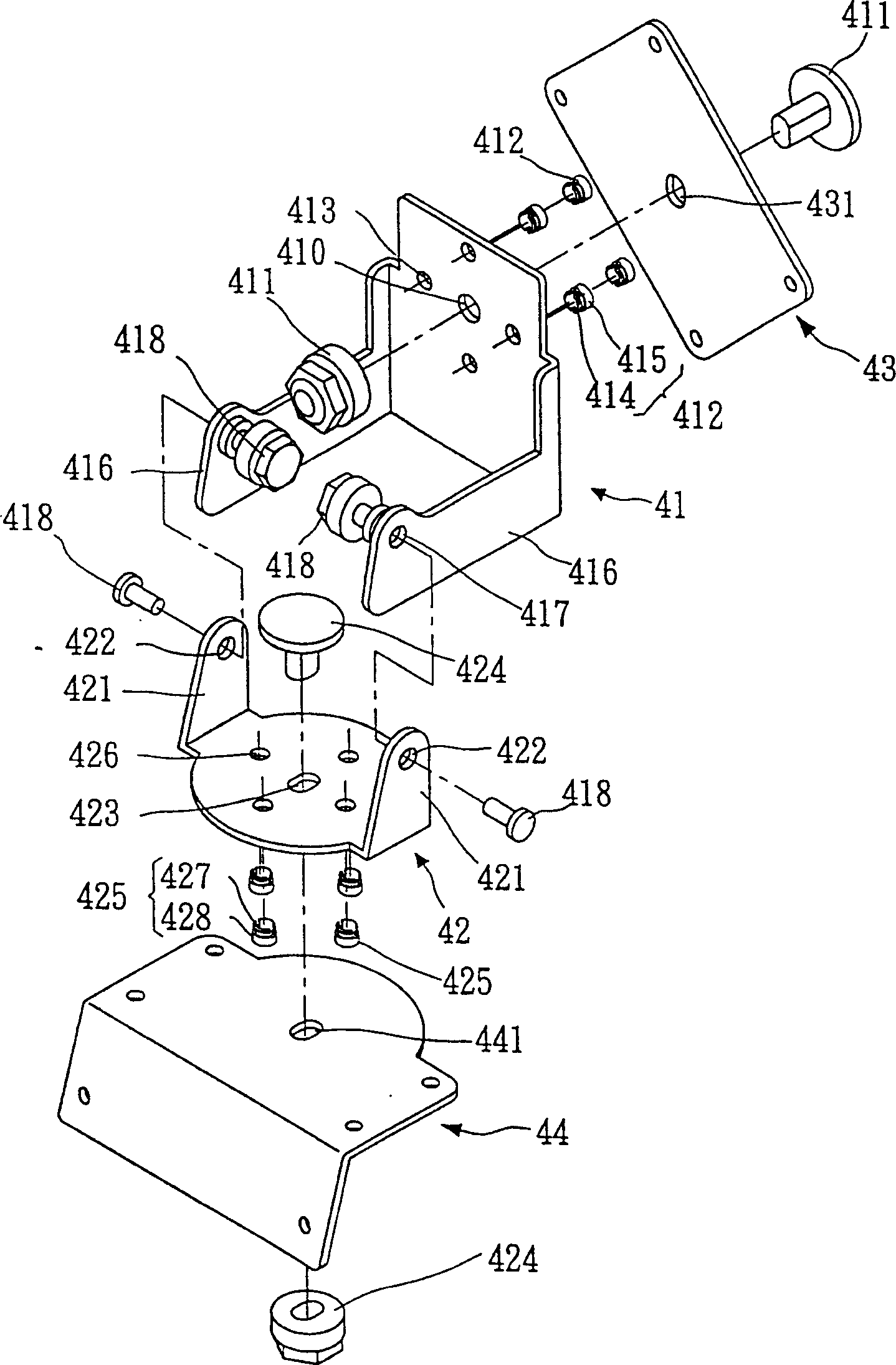

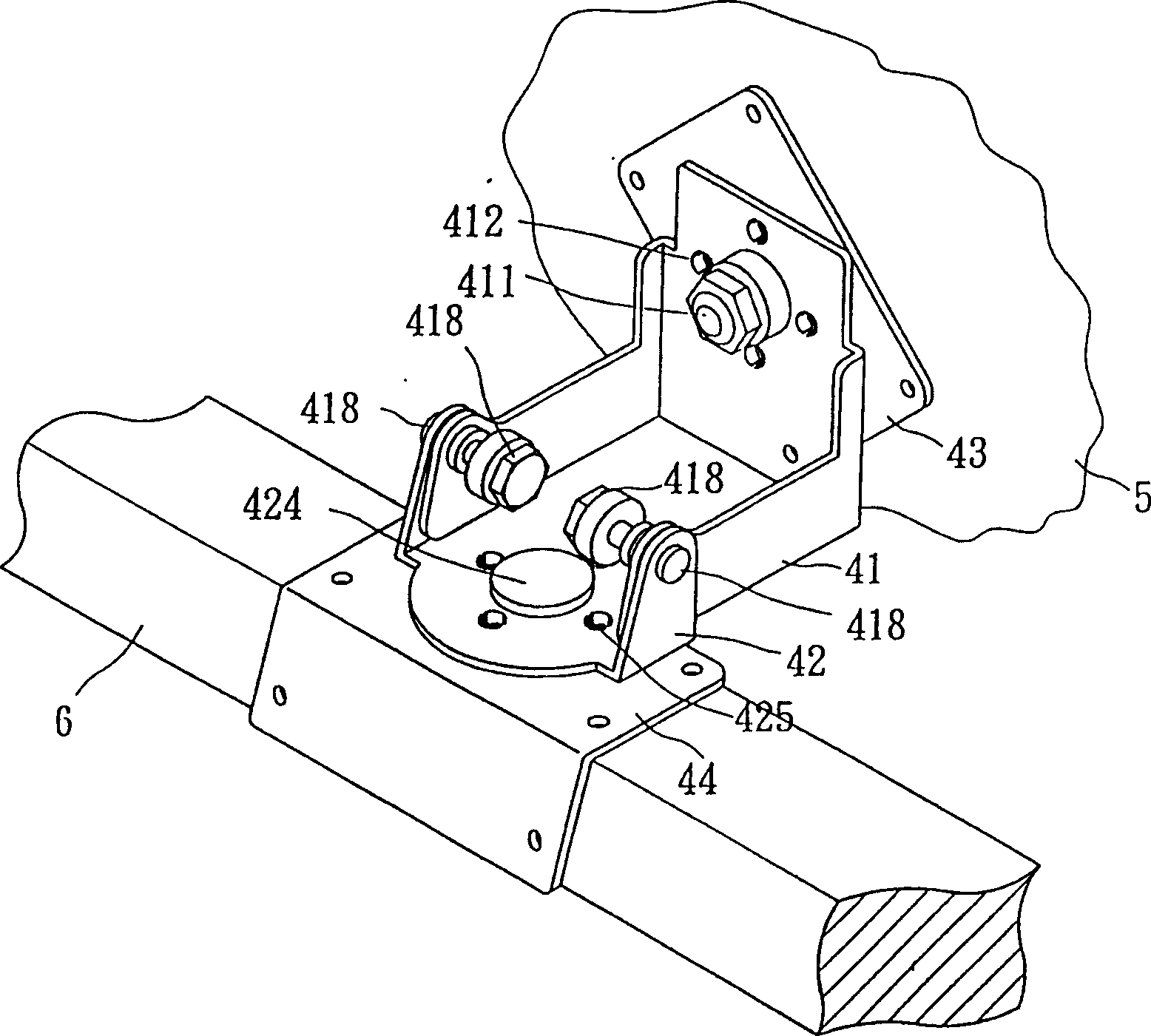

[0023] refer to figure 2 , The triaxial pivot structure 4 of the present invention includes an upper connecting plate 41 , a lower connecting plate 42 , an upper rotating plate 43 and a lower rotating plate 44 .

[0024] The upper connecting plate 41 is provided with a shaft hole 410 in the middle of its plate surface, and a first pivot 411 is combined on the shaft hole 410. The first pivot 411 is perpendicular to the upper connecting plate 41, and the upper connecting plate 41 is in the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com