Supersonic method of detecting the fixed-point liquid level in container

A technology for detecting containers and ultrasonic waves, which is applied in the direction of instruments, measuring devices, liquid level indicators, etc., and can solve problems that affect the popularization and application of detection methods, poor reliability, troublesome installation of detection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

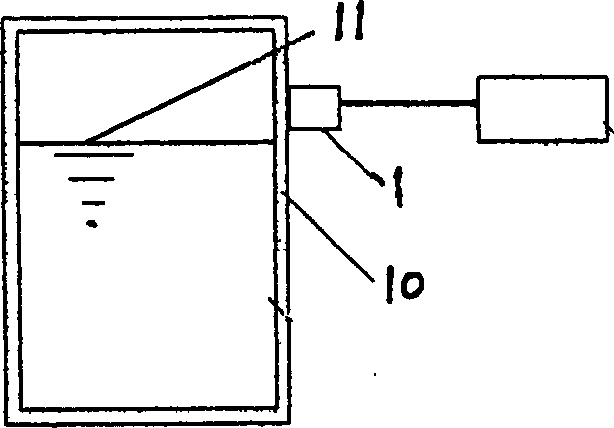

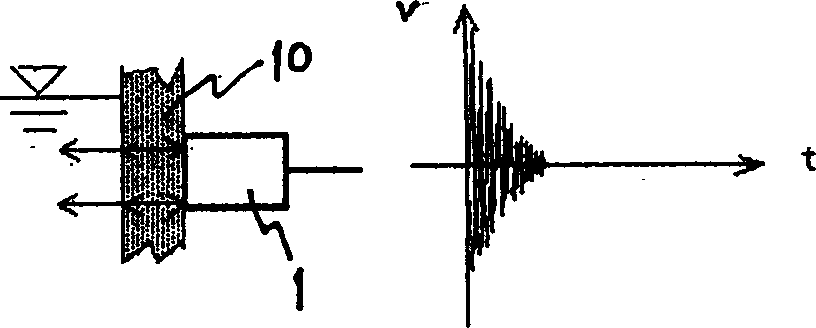

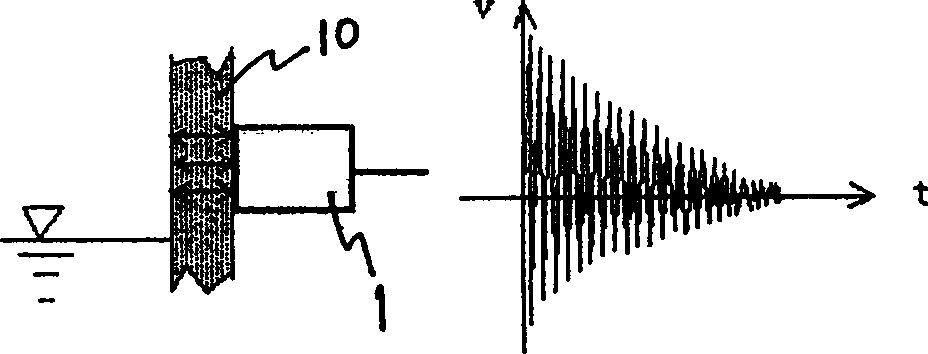

[0013] refer to Figure 1 to Figure 9 , the method of the present invention is carried out according to the following steps: 1.1 utilizes the ultrasonic sensor 1 that is coupled on the outer wall of the container to transmit high-frequency pulsed ultrasonic waves in the container through the container wall 10; 1.2 detects the ultrasonic residual vibration energy in the container wall 10 with the ultrasonic sensor 1 signal, that is, to measure the change of the aftershock energy signal; 1.3 compare the actually measured aftershock energy signal and attenuation characteristics with the pre-set standard eigenvalues of the aftershock energy signal to determine whether the liquid level 11 in the container has reached Control point; 1.3.1 When the measured residual vibration energy lasts for a short time, the residual vibration energy signal decays quickly, that is, the liquid level 11 reaches or exceeds the measurement control point; 1.3.2 When the measured residual vibration ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com