Ring hoop hold-down device for drum pedal

A hoop, pedal technology, applied in the direction of instruments, percussion instruments, music auxiliary equipment, etc., can solve problems such as inability to firmly clamp, poor, design limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention will be described in detail with reference to the drawings.

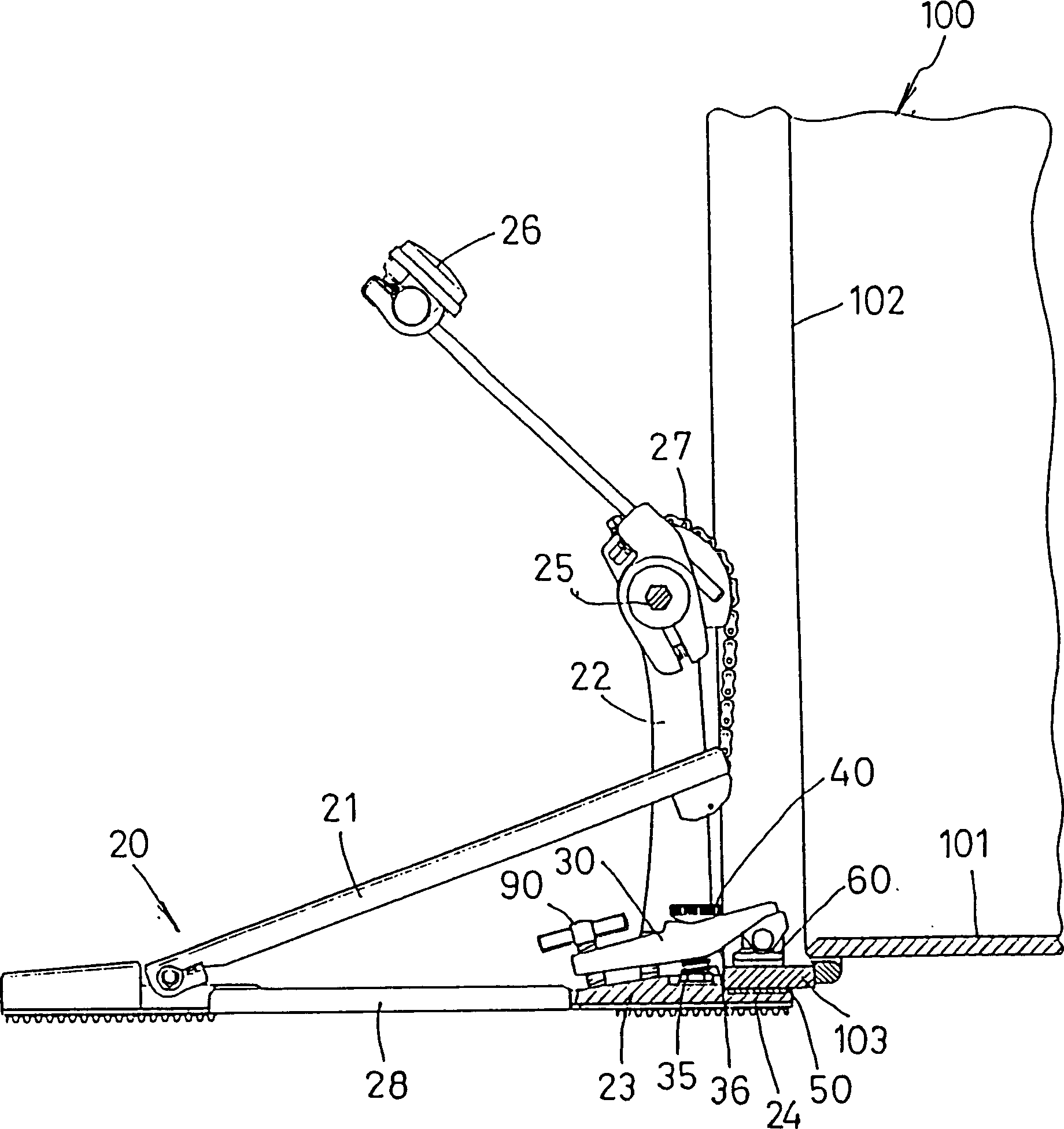

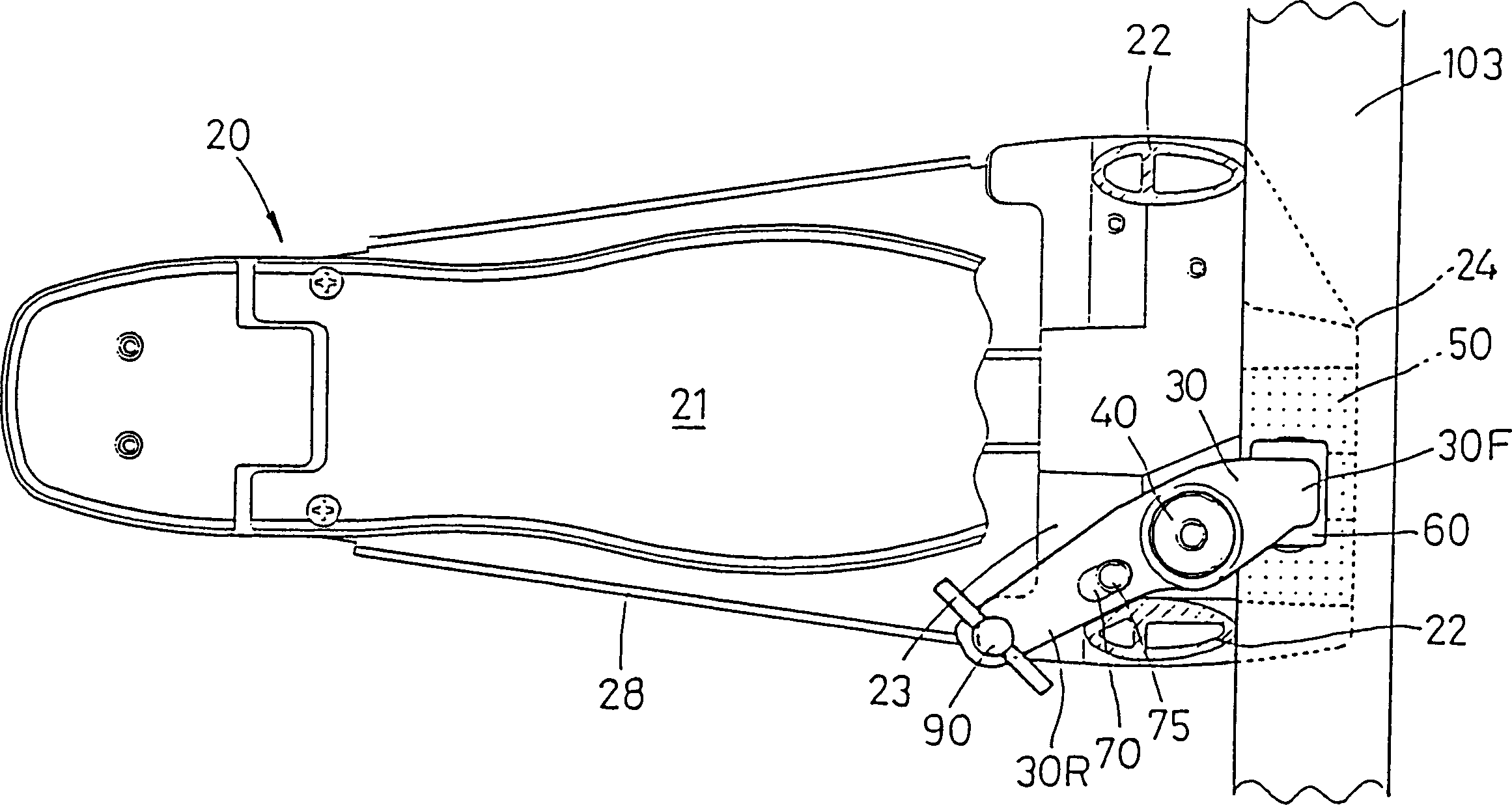

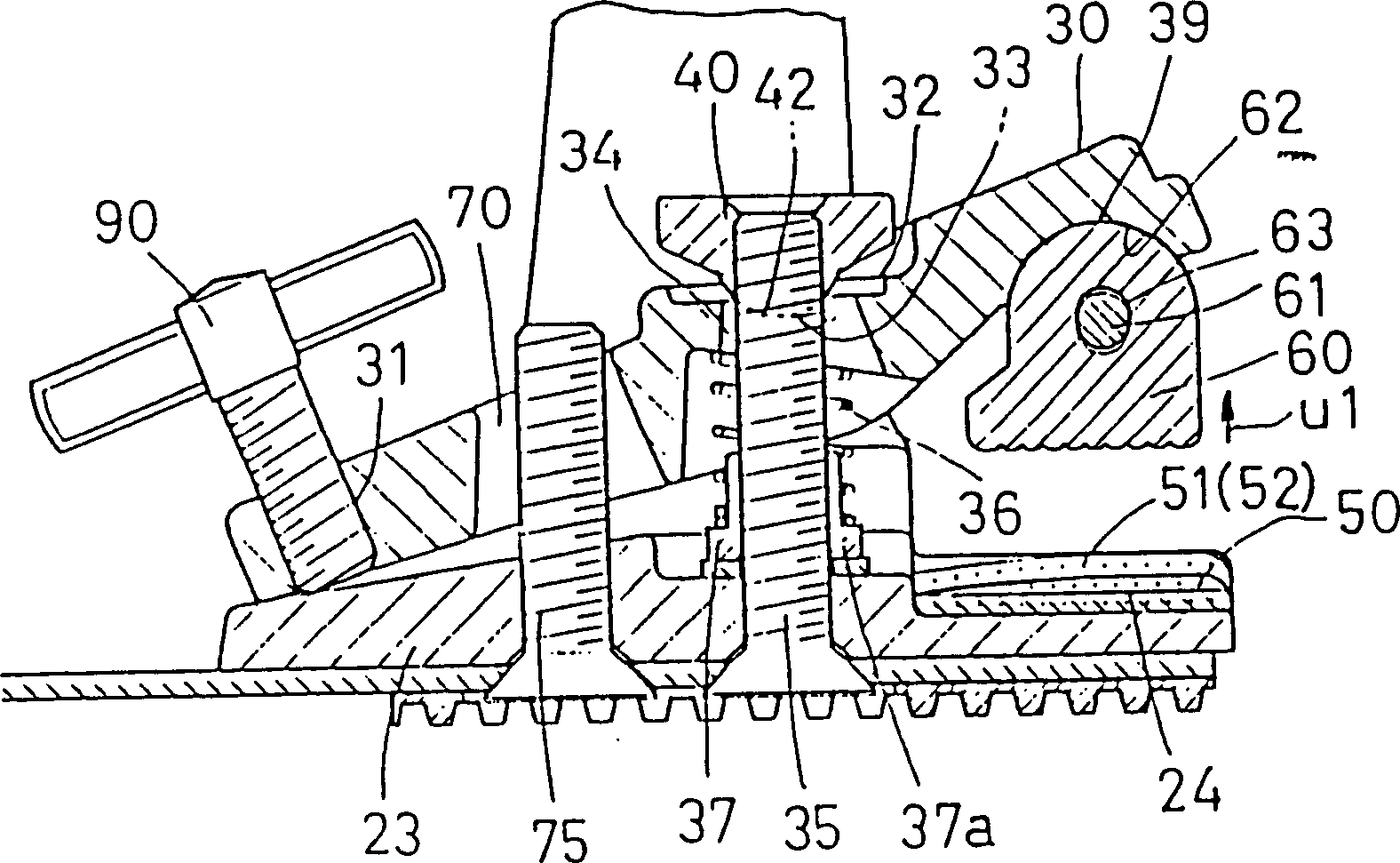

[0045] figure 1 The bass drum 100 shown has the same Figure 13 The description of the same structure, and the label 101 is a drum shell, 102 is a drum head, and 103 is a drum hoop. In addition, the illustrated drum pedal device 20 itself is also known in the past, and the label 21 is a drum pedal, 22 is a pillar, 23 is a pillar base on which the above-mentioned pillar 22 is erected, and 24 is a hoop at the front of the above-mentioned pillar base 23. Receiving part, 25 is the rotary shaft straddling the above-mentioned pillar 23, 26 is the beater installed on the above-mentioned rotary shaft 25, and 27 is a chain member that utilizes the pedal 21 to move the rotary shaft 25 up and down.

[0046] The hooping device of the present invention, as shown in the accompanying drawings, is provided between the front part of the hoop clip body 30 supported on the pillar base 23 of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap