Belt polishing machine

A technology of grinding machine and electric motor, which is applied in the direction of portable grinding bed, grinding/polishing equipment, grinding machine, etc., which can solve problems such as limitations and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

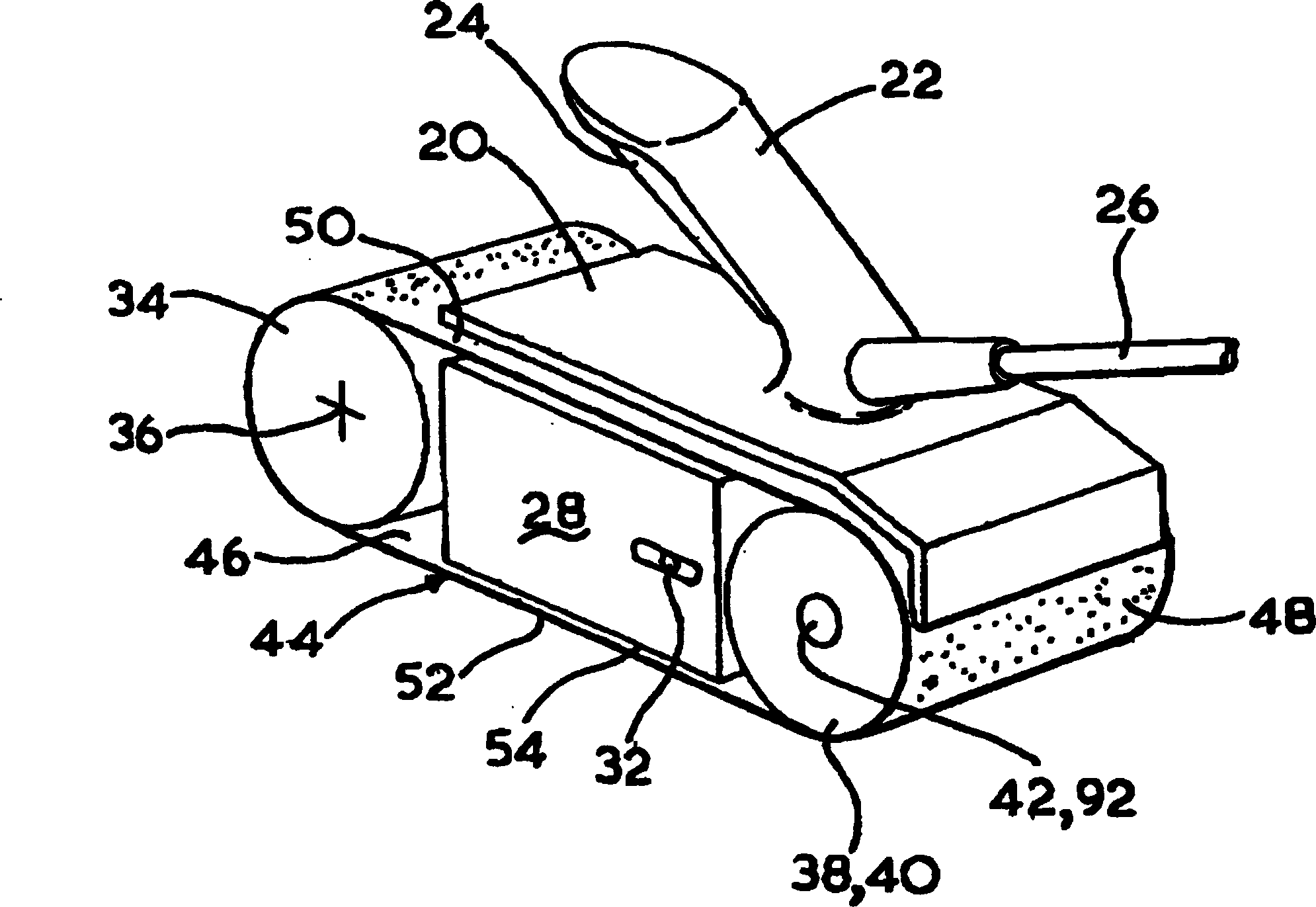

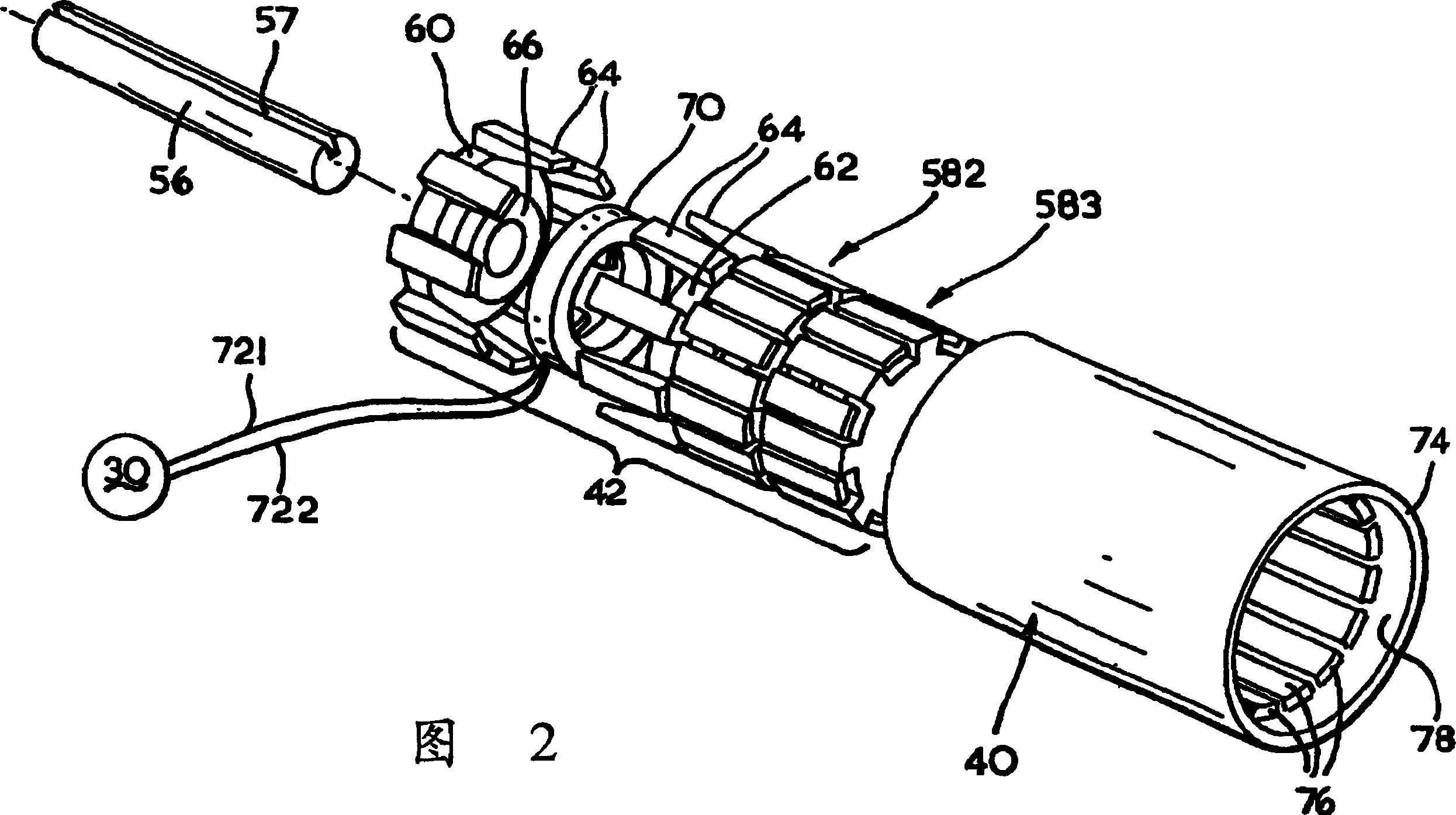

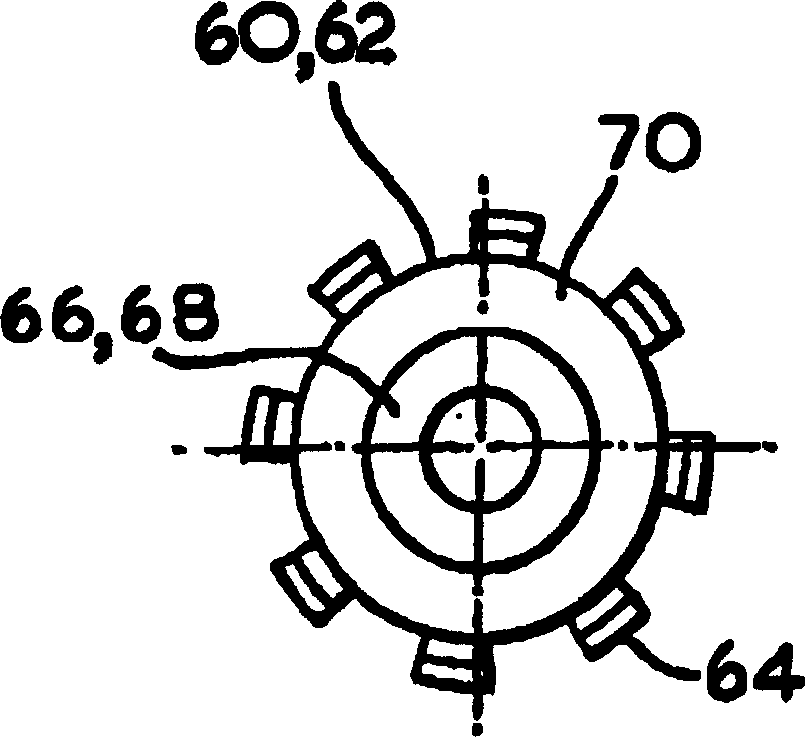

[0039] With reference to the accompanying drawings in particular figure 1 As shown, the belt sander includes a body part (20) having a handle (22), an electric trigger switch (24) located on said handle (22), and a rear end of the handle (22) into the body The input cable (26) in the part (20) and capable of transmitting current is connected to the main part (20) and includes a housing (28) with a power module (30) and a tension adjuster (32) of the belt, The driven roller (34) rotatably arranged on the shaft (36), the shaft mounted on the tensioner side of the belt, the driving roller (38) formed by the drum of the rotor of the motor, is rotated by the rotor The outer drum (40) surrounds the motor's stator (42), which is connected to the main body part (20) as is the shaft (36) connected to the belt tensioner (32) on the same side of the same side; the sandpaper belt (44) surrounding and supported by the driving roller (38) and the driven roller (34), wherein the housing (28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com