Acoustic touchscreen constrted directly on cathode ray tube

A touch screen, sound technology, applied in the input/output process of data processing, instruments, mechanical mode conversion, etc., can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

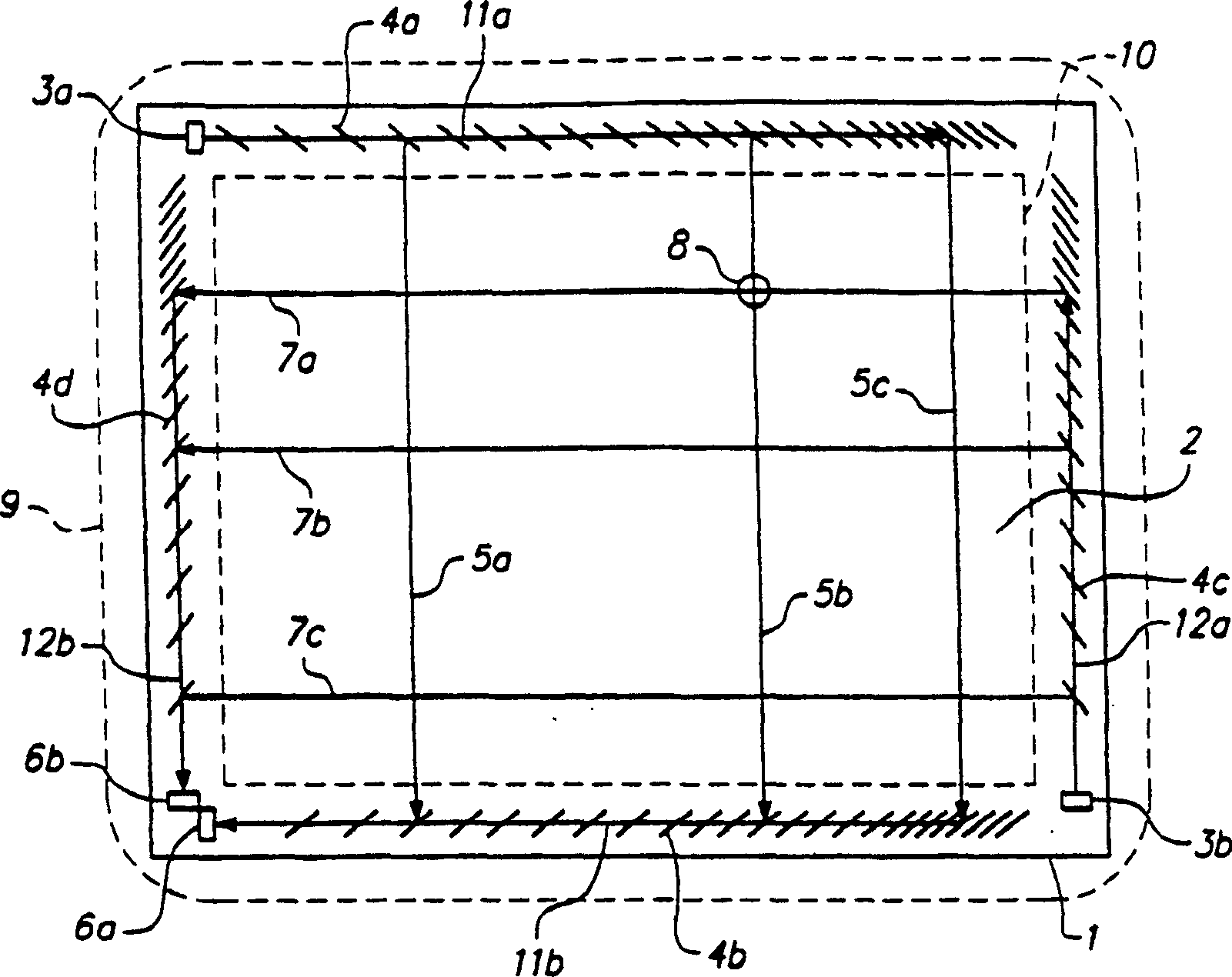

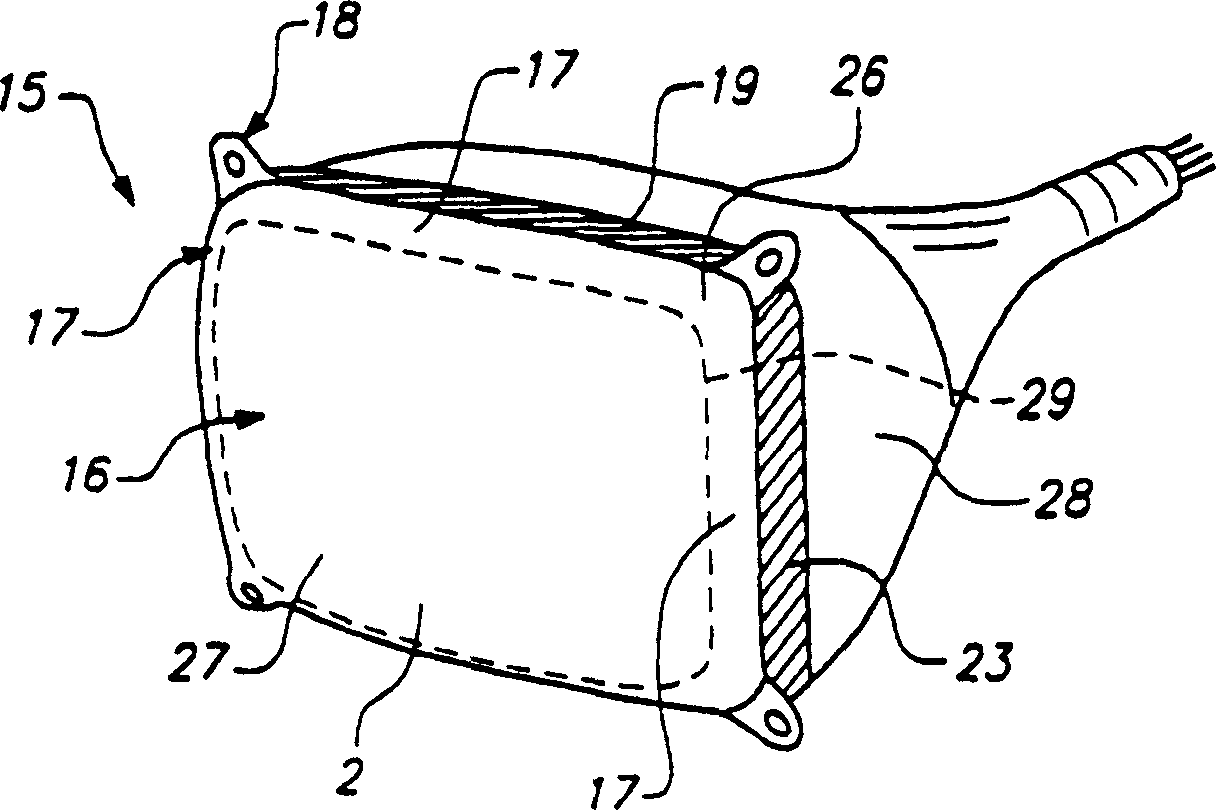

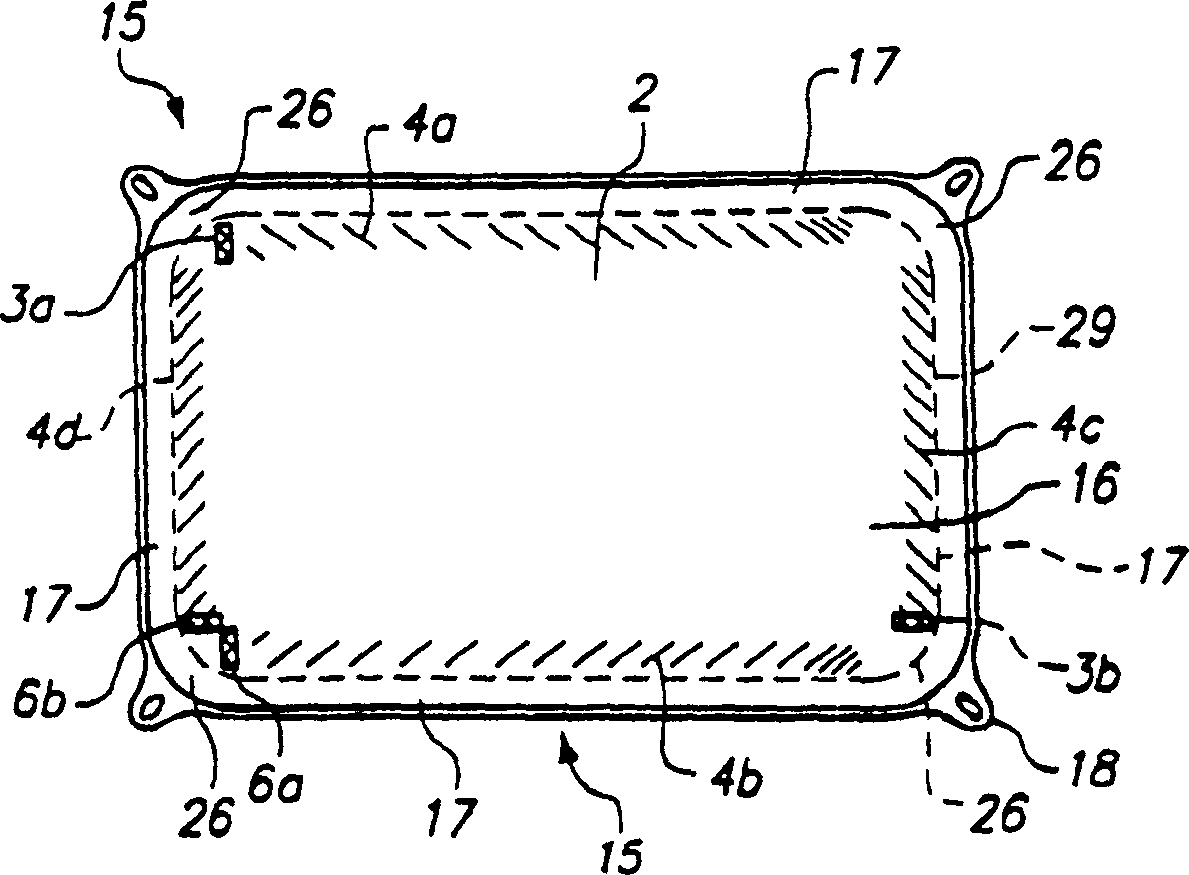

Embodiment Construction

[0061] The sensor typically applied to sound touch screens is a wedge sensor, as disclosed in Davis-Cannon et al., US 5,739,479 (1998), which is incorporated herein by reference. Therefore, this description specifically refers to wedge sensors, although our invention is not limited to wedge sensors. Other sensors may also be used, such as the interdigital sensor of Kent, US 5,708,461 (1998), as shown in Figure 4, which is incorporated herein by reference. Figure 4 here shows a cross-sectional view of a wedge sensor 20 mounted on the surface of the touch screen 1, and with a piezoelectric element 21 as a component, a coupling wedge 22, made of plastic, such as poly (methyl) Acrylate) (PMMA). The wedge shape 22 is adhered to the surface of the touch screen 1 by an adhesive, such as a UV curable adhesive, so that one is connected to the other audibly. The piezoelectric element 21 is mounted on the back of the coupling wedge 22 and is electrically connected to the electronic controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com