Technology for preparing electrostatic-type full-light switch for miniature machine

A technology of an all-optical switch and a manufacturing method, applied in the field of optoelectronics, can solve the problems of increased volume and cost, increased optical exchange pressure, low speed, etc., and achieves the effects of easy mass production, low manufacturing cost, and simple operation and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

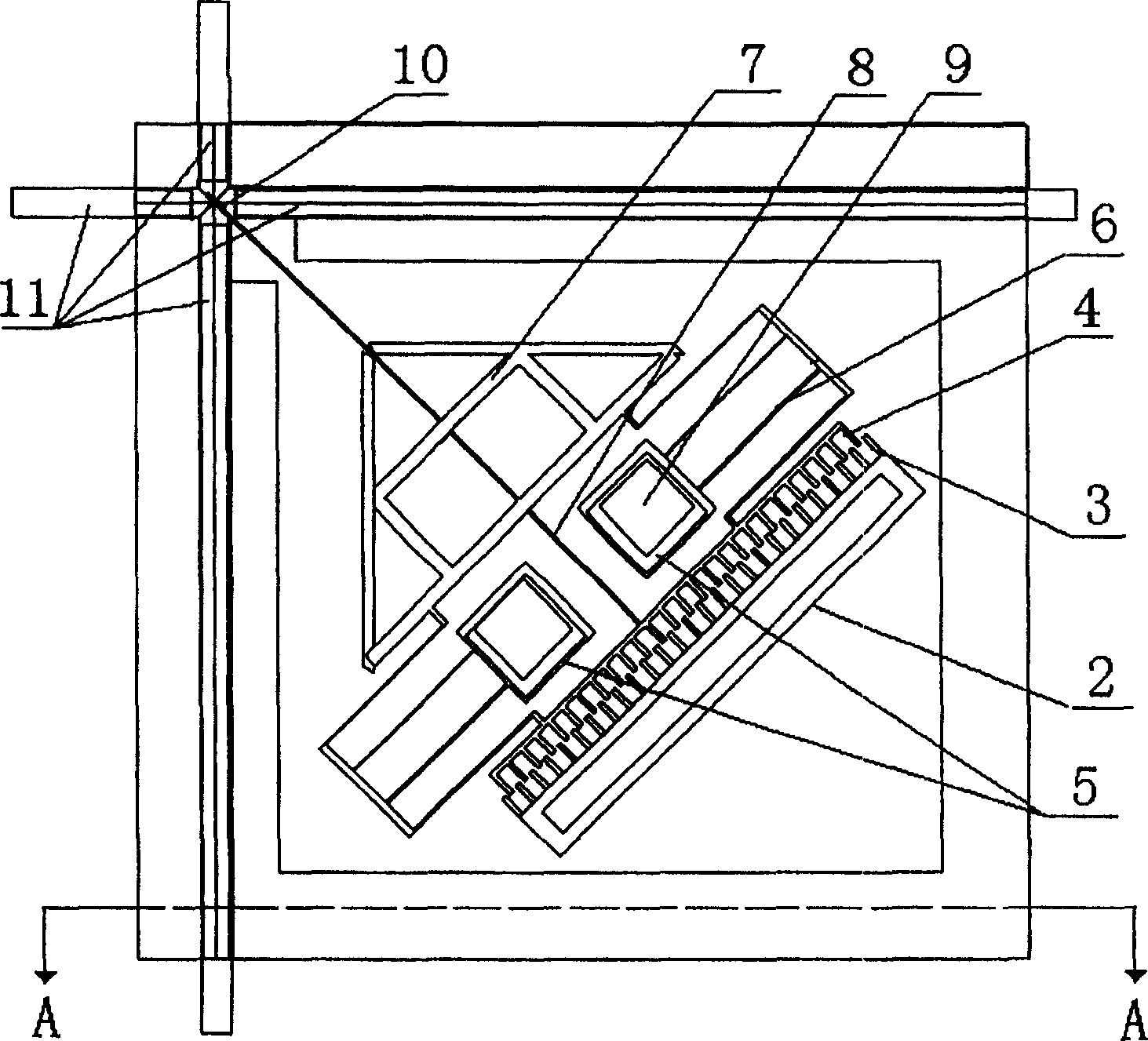

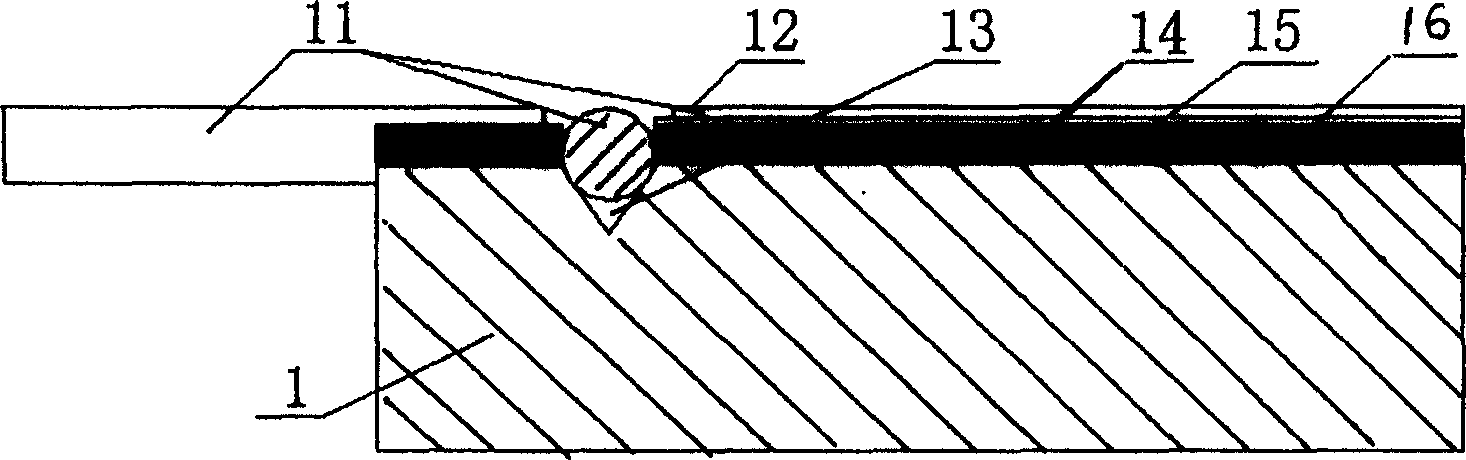

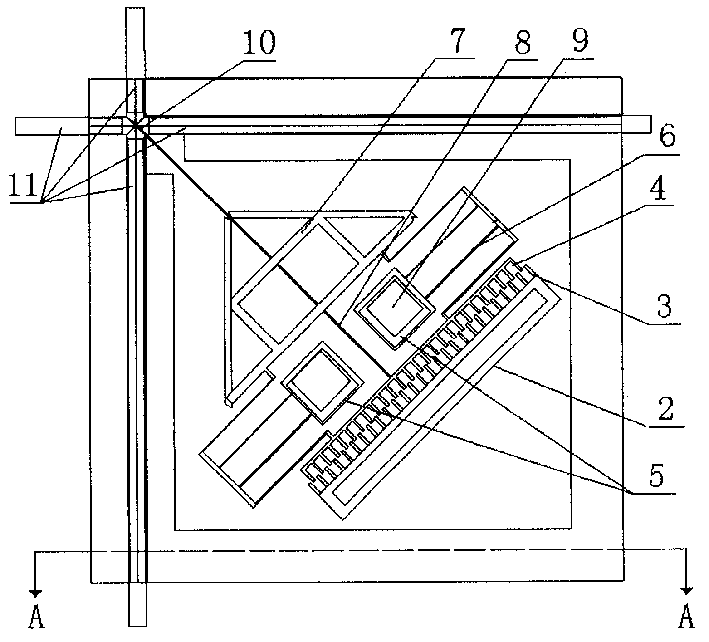

[0021] refer to figure 1 , figure 2 , the present invention takes the following steps:

[0022] (1) utilize a commercially available general-purpose diffusion furnace to diffuse a layer of boron-concentrated layer 14 on an N-type monocrystalline silicon 1 substrate. The thickness of the embodiment diffusion-concentrated boron layer 14 is 100,000 Å. A self-stopping layer etched by the method, and at the same time a P ++ The n-junction serves as electrical isolation between the fixed-tooth drive electrode 2 and the movable-tooth drive electrode 5 .

[0023] (2) Coat one layer of AZ1450 type photoresist 15 on the concentrated boron layer 14, the thickness of the embodiment coating photoresist 15 is 8000 Å, and bake 15 minutes at temperature 100 ℃ with oven.

[0024] (3) Place an electrode mask plate on the photoresist 15, expose it to the position on a conventional exposure machine for 10 seconds, and then put it in a developing solution with a ratio of tetramethylammonium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com