Manufacturing method of plasma display panel silver electrode

A production method and plasma technology, which is applied in electrode system manufacturing, cold cathode manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of lowering the working performance of the whole board, serious disconnection problems, and increasing workload, etc., to achieve The effect of reducing the workload of patching lines, reducing production costs and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

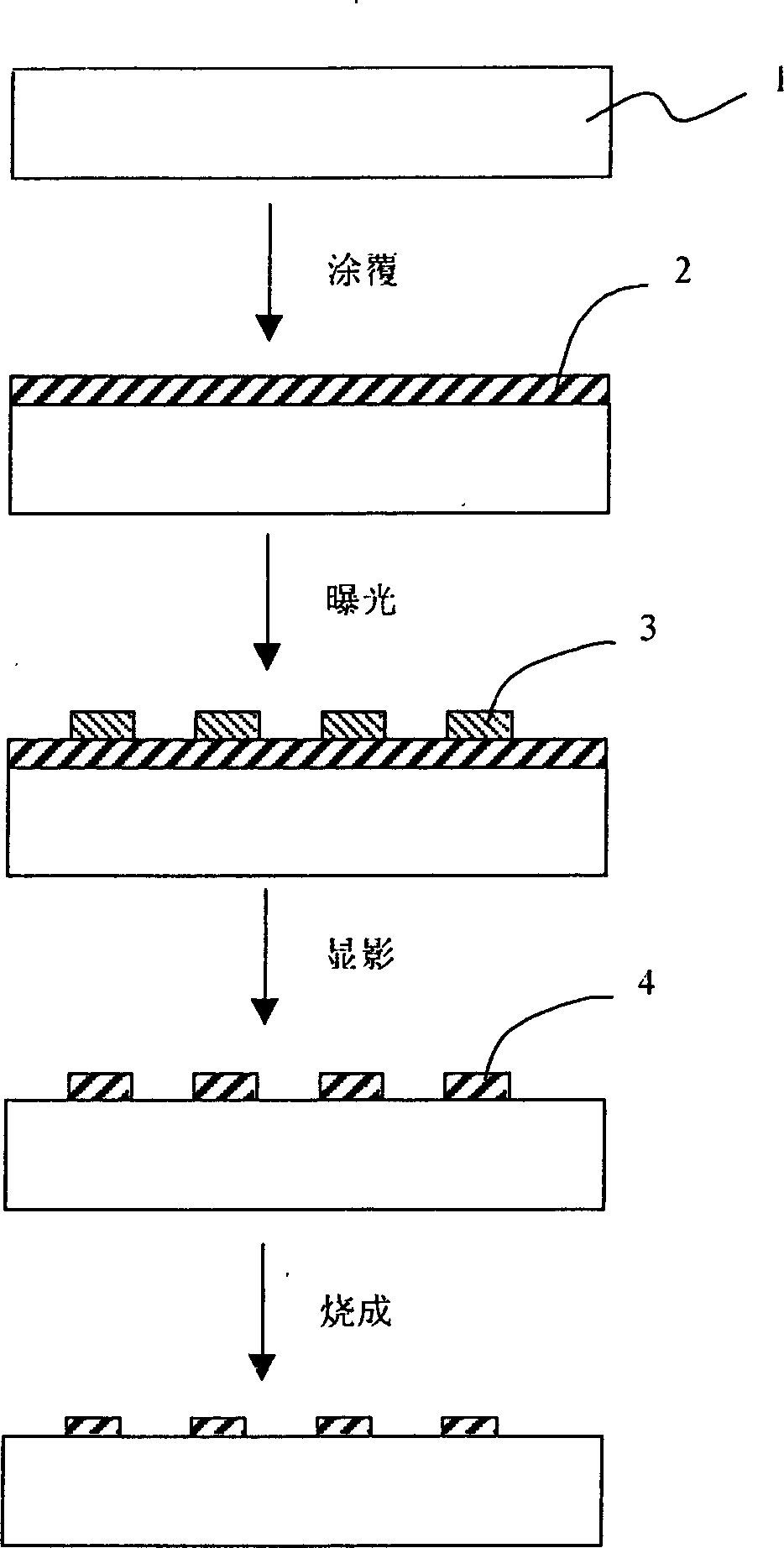

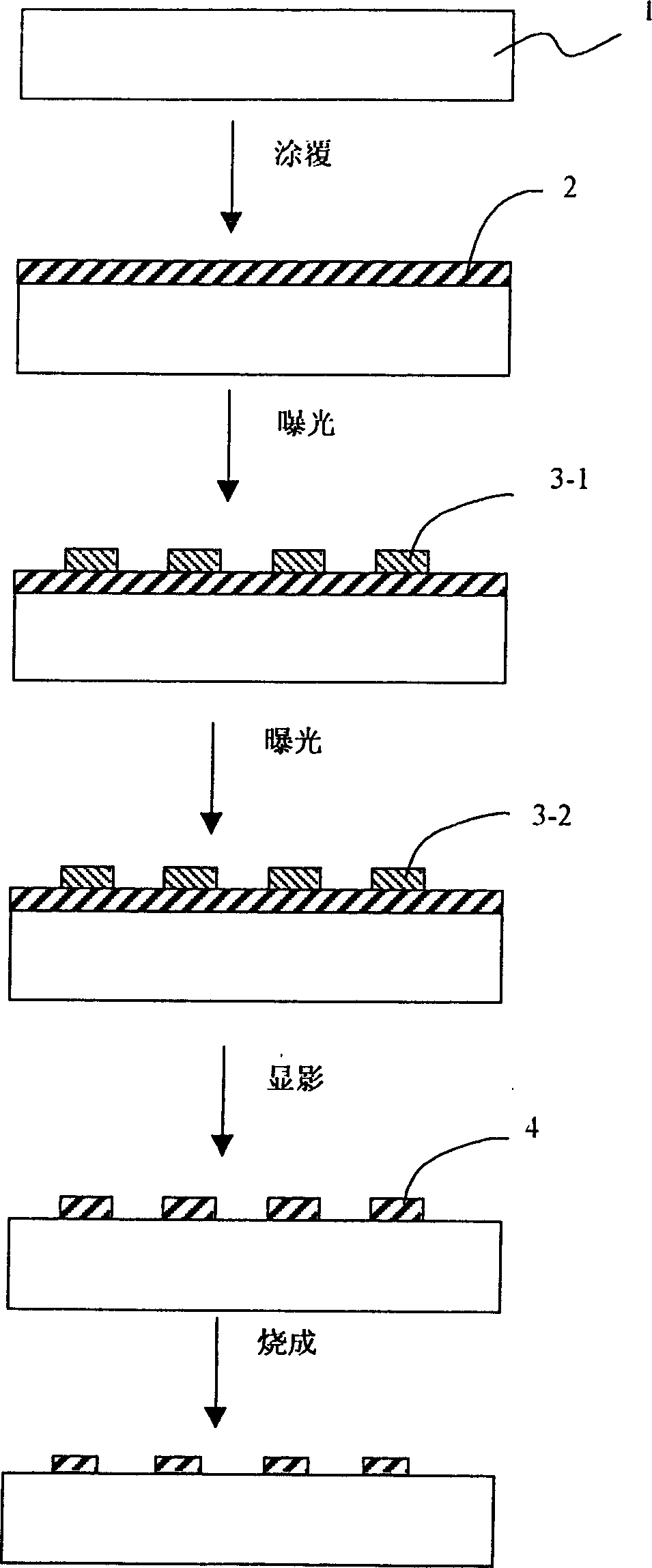

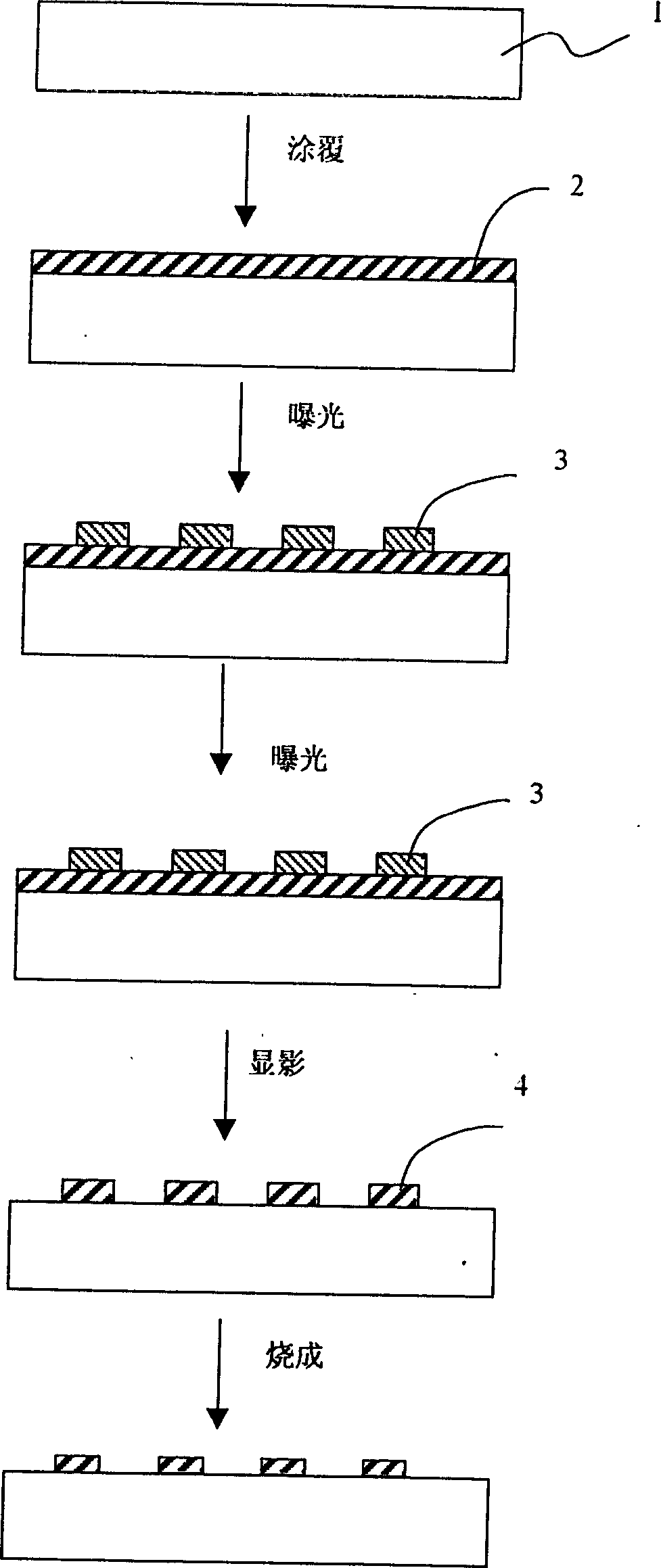

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] figure 2 , 3 It is an explanatory diagram showing a method of double exposure of a photolithographic silver electrode according to the embodiment.

[0021] A negative photosensitive silver paste 2 is uniformly coated on a large area of the entire glass substrate 1 and dried.

[0022] Cover the first mask 3-1 on the negative photosensitive silver layer for the first exposure, and the exposure time is set to t ( t min ≤ t 1 2 t max ) .

[0023] Use the second mask 3-2 to completely coincide with the position of the first exposure through strict registration and then perform the second exposure. The exposure time is still t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com