Ignitor

An ignition device and injection nozzle technology, used in combustion ignition, intermittent spark ignition, igniter with fuel, etc., can solve the problems of complex structure, unavoidable foreign matter entry and adhesion, etc. failure, the effect of maintaining ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

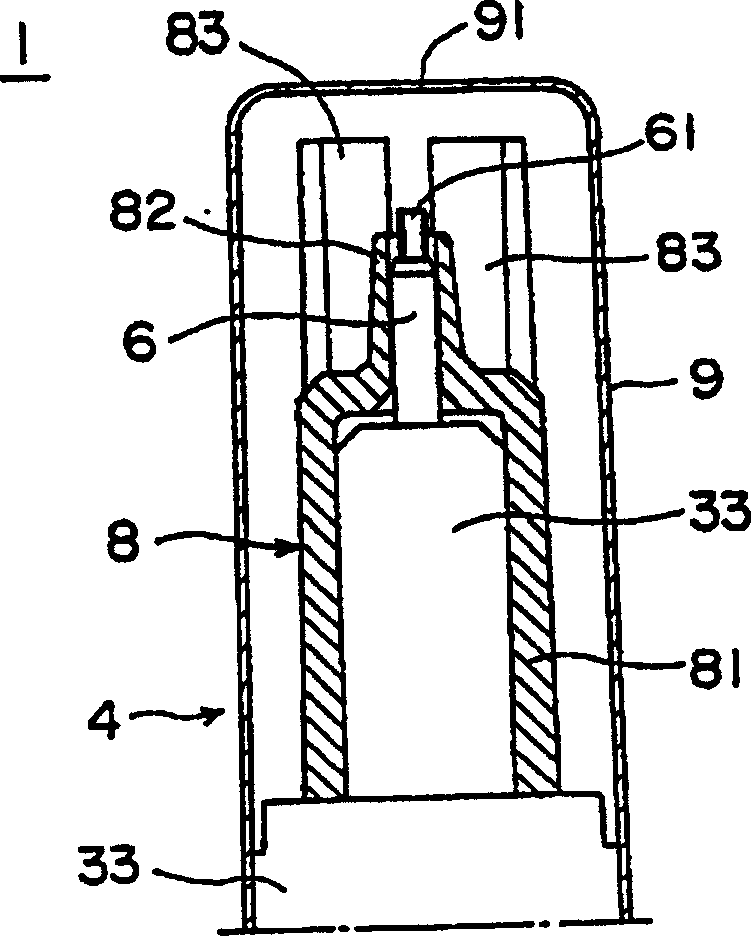

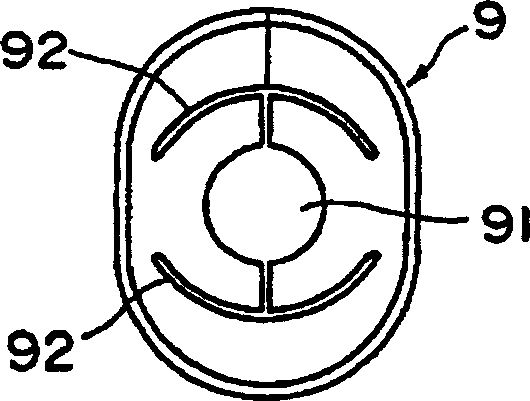

[0024] Now refer to the attached drawings in more detail and see first Figure 4 , It shows the ignition electrode 1 as a preferred embodiment of the ignition device according to the present invention. The ignition electrode (ignition device) 1 is composed of a pressure tank part 2 for containing high-pressure gas such as butane, a main body part 3 having a control device 5 (control knob) for completing the ignition operation, and a main body part 3 The part 3 is formed by the electrode part 4 extending forward.

[0025] The pressure tank part 2 of the ignition electrode 1 is composed of a cylindrical tank body 21 with a bottom, a blocking device 22 for blocking the opening of the tank body 21 and a tank cover 23. The blocking device 22 is equipped with a known valve mechanism 7 for supplying air to the blocking device 22. This valve mechanism 7 has a nozzle device 71 in its central part, and the nozzle device 71 is opened and closed by a generally L-shaped lever 72 installed at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com