Medium-speed coal-mill direct-firing pulverizing combustion system for burning high-moisture lignite

A technology of combustion system and coal pulverizer, applied in combustion method, combustion equipment, block/powder fuel preparation, etc., can solve problems such as difficulty in adjusting means, and achieve the effect of ensuring ignition and combustion performance and improving drying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

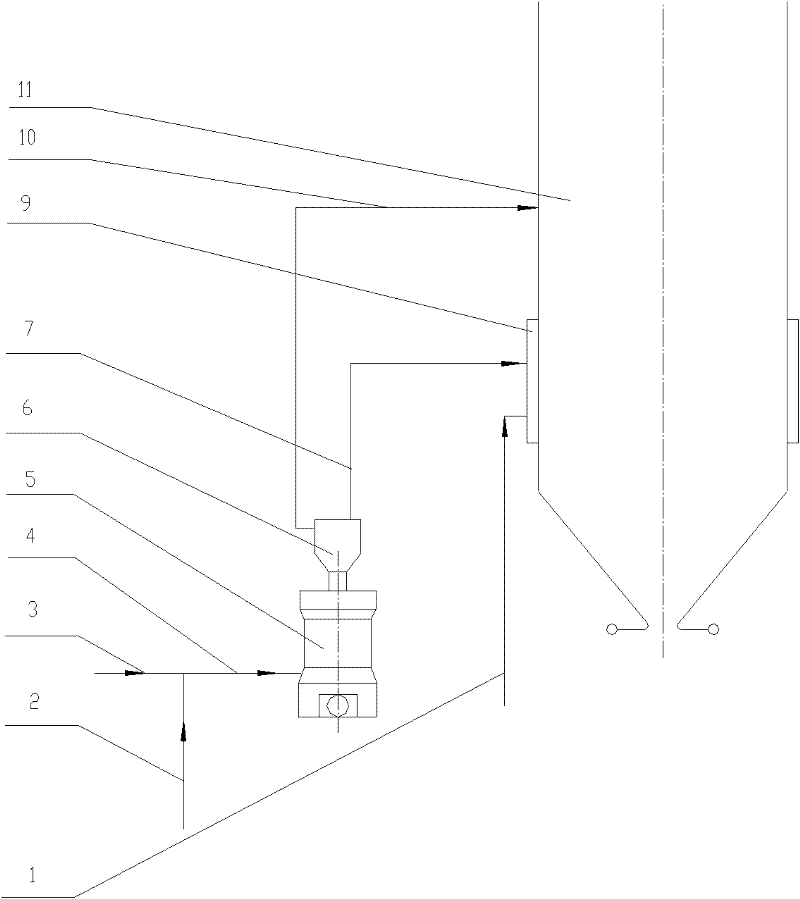

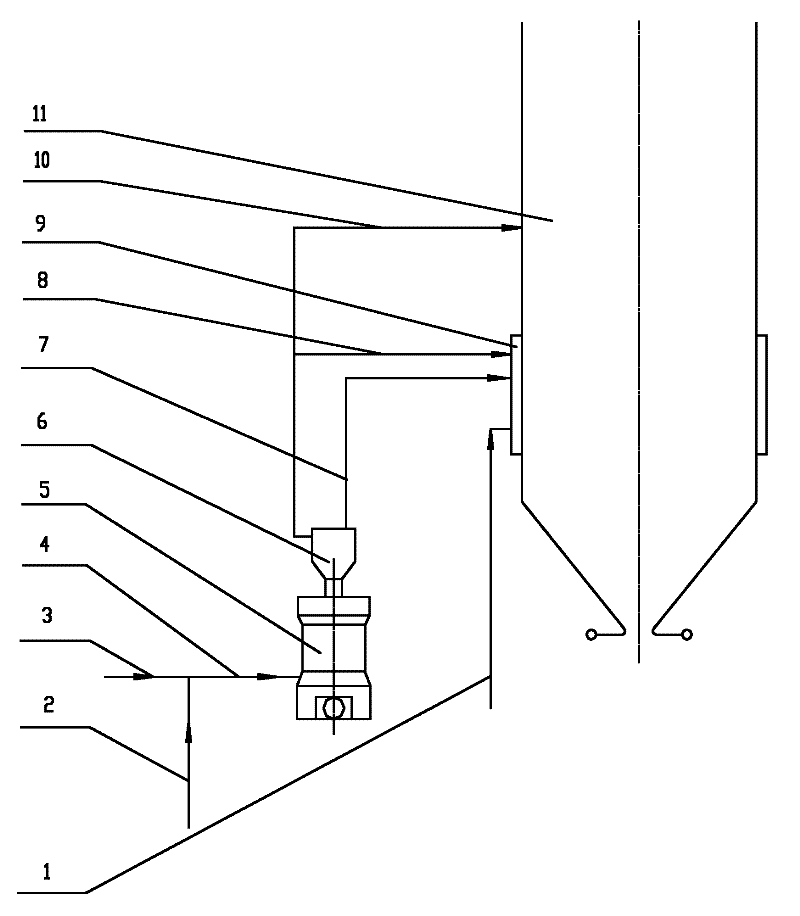

[0014] Embodiment 1: see figure 1 , the present invention includes a burner 9 arranged on the furnace 11 and a primary secondary air 1 connected to the burner 9, a medium-speed coal mill 5 is arranged outside the furnace 11, and the hot primary air 3 is mixed with the temperature-regulating air 2 to form After the drying air 4 is sent to the medium-speed coal mill 5, the outlet of the medium-speed coal mill 5 is provided with a pulverized coal concentrator 6, and the pulverized coal concentrator 6 separates the primary air-powder air flow into two phases, thick and thin, and sends them to the furnace 11 to participate in the process. combustion. The said dense-phase airflow is sent into the furnace 11 through the burner 9 as the primary wind powder airflow 7, and the rest of the light-phase airflow is directly sent into the upper part of the furnace 11 as OFA or SOFA10. Supplement the lack of secondary air momentum caused by the increase of primary air volume, so that a reaso...

Embodiment 2

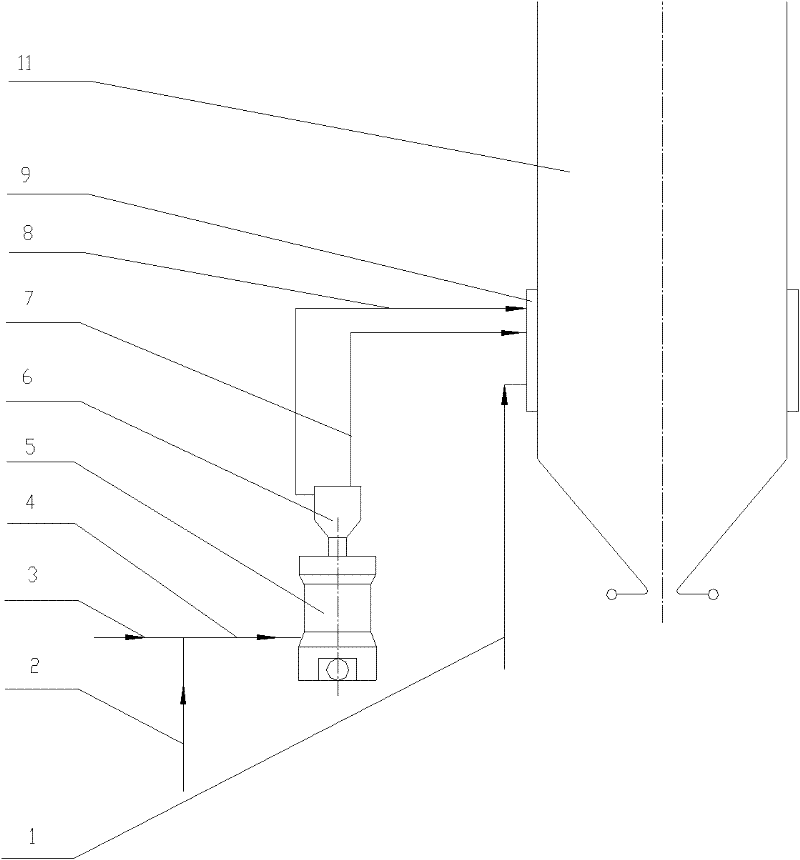

[0015] Example 2, see figure 2 , The dense-phase airflow of this embodiment is sent into the furnace 11 through the burner 9 as the primary wind powder airflow 7, and the remaining light-phase airflow is sent into the furnace chamber through the burner 9 as the secondary air 8. Supplementing the amount of oxygen required in the later stage of combustion and the lack of momentum of the secondary air caused by the increase of the primary air volume make the furnace organize a reasonable combustion dynamic field. Other connections are the same as in Embodiment 1.

[0016] The present invention divides one stream of air at the outlet of the original coal mill into two streams of thick and thin, the purpose of which is to increase the air volume at the inlet of the coal mill to solve the drying problem of high-moisture lignite, and at the same time reduce the primary air flow rate through the separation of the pulverized coal concentrator. And the primary wind speed is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com