A horizontal spray ignition device

An ignition device, horizontal technology, applied in the direction of combustion ignition, combustion method, lighting and heating equipment, etc., can solve the problems of lack of oxygen around the ignition head, harmful gas environmental pollution, toxic and combustible gas, etc., to achieve enhanced environmental protection effect, Guarantee the ignition effect and improve the success rate of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

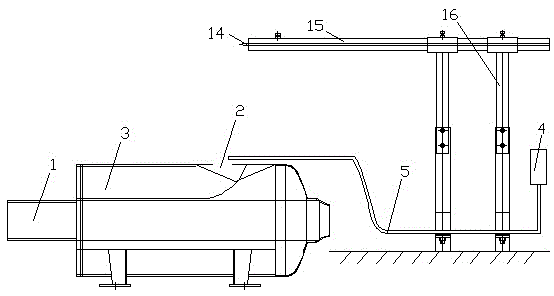

[0028] A horizontal spray ignition device, comprising a central tube 1, an outer cylinder 3 with a nozzle opening 2, an ignition rod 15 with an ignition head 14 and a bracket 16 for fixing the ignition rod 15, the central pipe 1 communicates with the outer cylinder 3, It also includes an oxygen-increasing component, which includes a gas supply device 4 and an air intake pipe 5 , one end of the air intake pipe 5 communicates with the gas supply device 4 , and the other end is placed at the discharge port 2 of the outer cylinder 3 .

[0029] This embodiment is the most basic implementation mode, with a simple structure. The gas supply device 4 can deliver a large amount of air to the bottom of the ignition head 14 through the intake pipe 5, so that sufficient oxygen can be dispersed around the ignition head 14, and the success rate of ignition of the combustible gas can be improved. At the same time, sufficient oxygen can fully burn toxic and combustible gases, enhancing the envi...

Embodiment 2

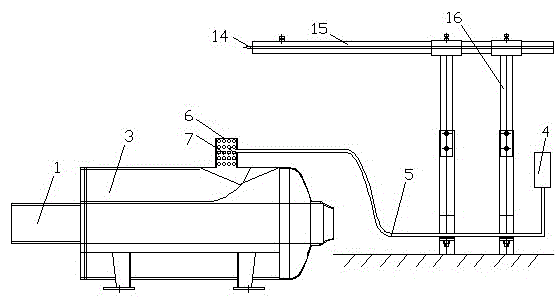

[0031] A horizontal spray ignition device, comprising a central tube 1, an outer cylinder 3 with a nozzle opening 2, an ignition rod 15 with an ignition head 14 and a bracket 16 for fixing the ignition rod 15, the central pipe 1 communicates with the outer cylinder 3, It also includes an oxygen-increasing component, which includes a gas supply device 4 and an air intake pipe 5 , one end of the air intake pipe 5 communicates with the gas supply device 4 , and the other end is placed at the discharge port 2 of the outer cylinder 3 .

[0032] The oxygen-increasing assembly also includes an oxygen dispersion cover 6, and the cover wall of the oxygen dispersion cover 6 is provided with an air circulation hole 7, and the oxygen dispersion cover 6 communicates with the discharge port 2 of the outer cylinder 3, and the air intake pipe 5 located at the discharge port 2 One end stretches in the oxygen dispersion cover 6.

[0033] This embodiment is a preferred implementation mode. The a...

Embodiment 3

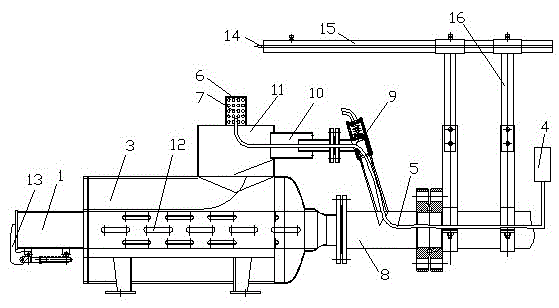

[0035] A horizontal spray ignition device, comprising a central tube 1, an outer cylinder 3 with a nozzle opening 2, an ignition rod 15 with an ignition head 14 and a bracket 16 for fixing the ignition rod 15, the central pipe 1 communicates with the outer cylinder 3, It also includes an oxygen-increasing component, which includes a gas supply device 4 and an air intake pipe 5 , one end of the air intake pipe 5 communicates with the gas supply device 4 , and the other end is placed at the discharge port 2 of the outer cylinder 3 .

[0036] The oxygen-increasing assembly also includes an oxygen dispersion cover 6, and the cover wall of the oxygen dispersion cover 6 is provided with an air circulation hole 7, and the oxygen dispersion cover 6 communicates with the discharge port 2 of the outer cylinder 3, and the air intake pipe 5 located at the discharge port 2 One end stretches in the oxygen dispersion cover 6.

[0037] It also includes a shunt pipe 8 communicated with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com