Pulverized coal concentration regulating device

A technology of concentration adjustment and pulverized coal, which is applied in the direction of adjusting fuel supply, combustion method, and control of combustion, and can solve problems such as poor ignition effect, changes in ventilation volume and pressure, and adverse effects on ignition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

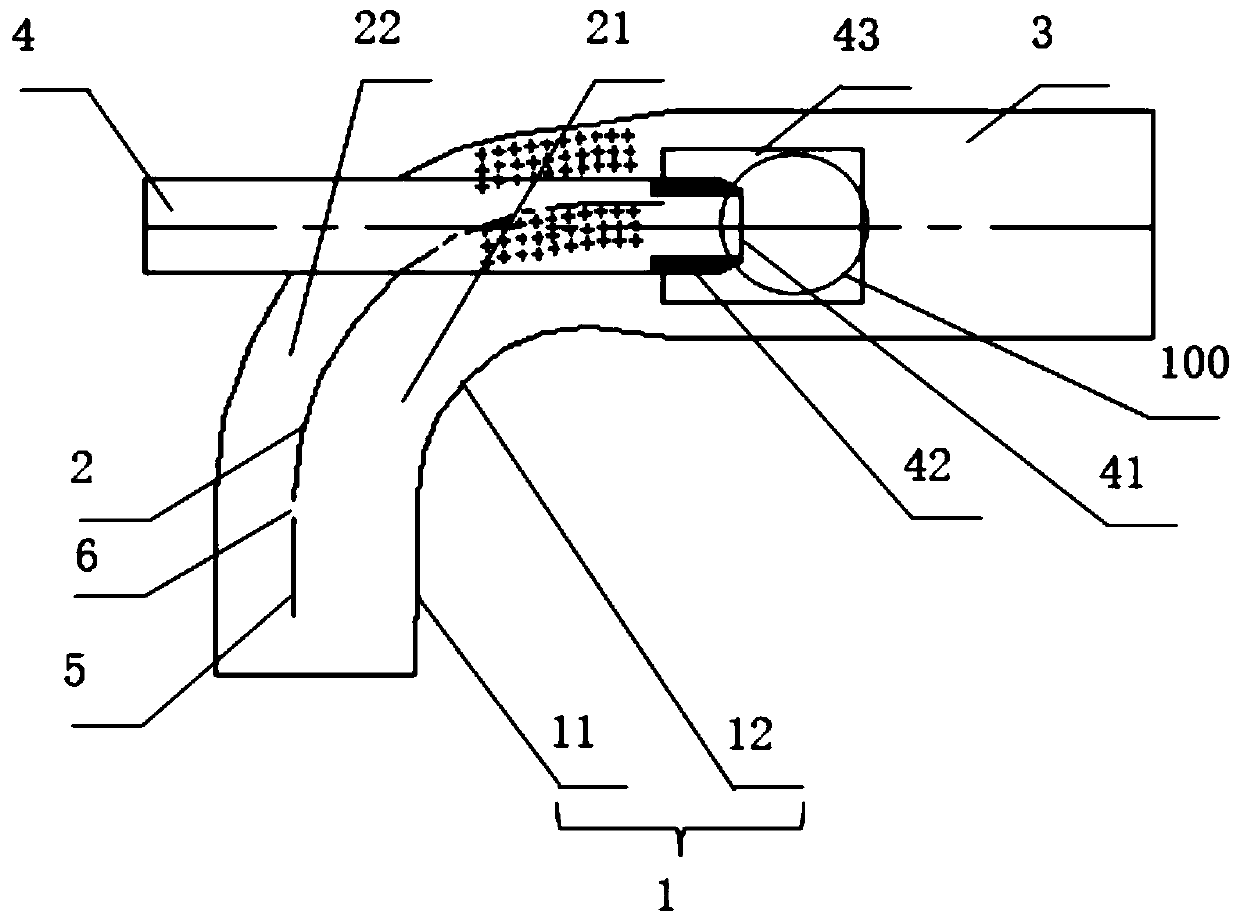

[0035] The invention provides a pulverized coal concentration adjustment device, such as figure 1 As shown, the pulverized coal concentration regulating device includes a pulverized coal pipe 1, a combustion chamber 3, an igniter 4 and a regulating plate 5, the combustion chamber 3 is installed at the end of the pulverized coal pipe 1, and the pulverized coal pipe 1 is used to feed the combustion chamber The pulverized coal airflow is conveyed in the body 3, and the pulverized coal airflow burns in the combustion chamber 3. The igniter 4 is connected to the combustion chamber 3, and the end of the igniter 4 is inserted into the combustion chamber 3 for ignition and combustion. The pulverized coal in the cavity 3 realizes ignition; the adjusting plate 5 is arranged in the inner cavity of the pulverized coal pipe 1, and is rotatably connected to the inner wall of the pulverized coal pipe 1, so that the amount of pulverized coal entering the conveying inner chamber 21 can be contr...

Embodiment 2

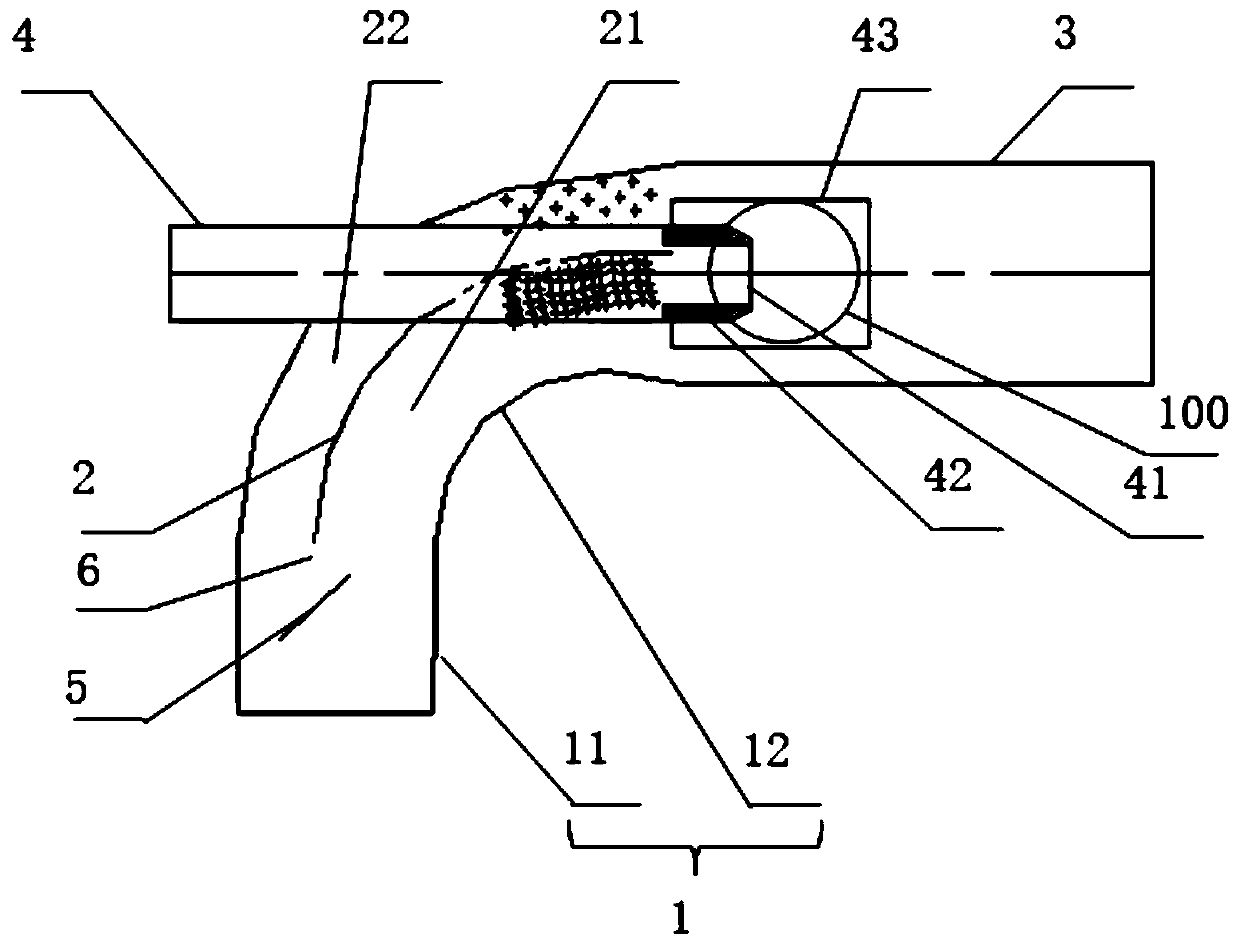

[0043] In this example, if Figure 4 As shown, the difference between the pulverized coal concentration adjustment device and the first embodiment is that the first embodiment changes the distribution ratio of the pulverized coal in the conveying inner chamber 21 and the outer chamber 22, and then controls the amount of concentrated coal powder entering the core ignition area 100, The rotating shaft in the pulverized coal regulating device provided in this embodiment is arranged in the delivery outer cavity 22 of the elbow 12 to change the distribution relationship of the pulverized coal input inside the outer cavity 22 .

[0044] In this embodiment, when the operating condition of the pulverized coal burner changes, if the splitter plate is rotated to change the distribution of pulverized coal in the outer chamber 22, the pulverized coal in the outer chamber 22 will be distributed to the pulverized coal in the core ignition area 100. The amount is increased to adapt to change...

Embodiment 3

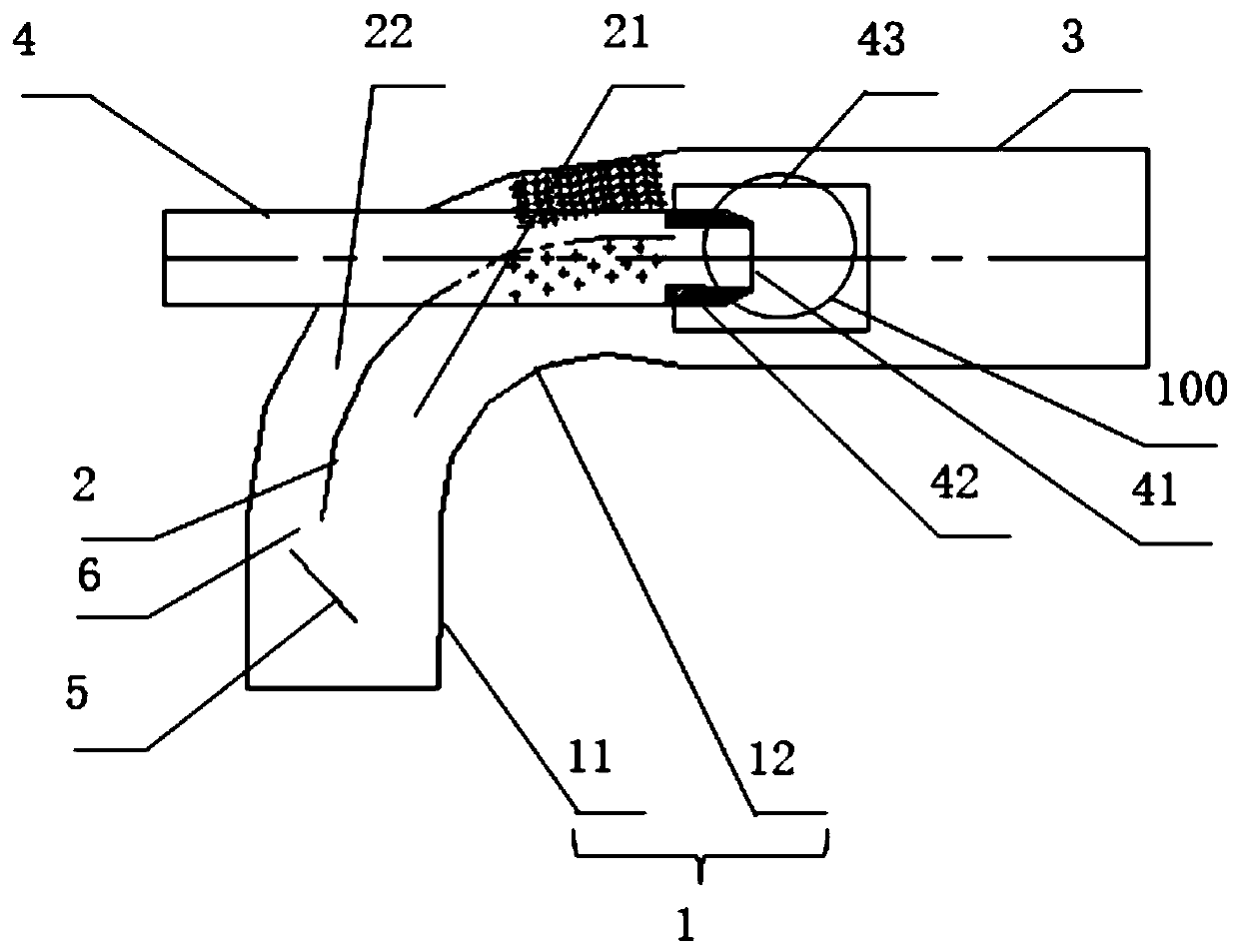

[0046] In this example, if Figure 5 As shown, the difference between the pulverized coal concentration adjustment device and the first embodiment is that the first embodiment changes the distribution ratio of the pulverized coal in the conveying inner chamber 21 and the outer chamber for conveying, and then controls the amount of concentrated pulverized coal entering the core ignition area 100. The rotating shaft in the pulverized coal regulating device provided in the embodiment is set in the conveying cavity 21 of the elbow 12 to change the distribution relationship of pulverized coal inside the input cavity 21 .

[0047] In this embodiment, when the operating condition of the pulverized coal burner changes, if the splitter plate is rotated to change the distribution of pulverized coal in the delivery cavity 21, the pulverized coal in the delivery cavity 21 will be distributed to the coal in the core ignition area 100. The amount of powder is increased to adapt to changes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com