Non-return valve and non-return valve assembly

A one-way valve and component technology, used in lift valves, control valves, pump components, etc., can solve problems such as disturbing the fluid flow path, reducing the overall efficiency of the compressor, loud noise, etc., to prevent noise and minimize fluid flow interference. , the effect of improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] According to the present invention, the one-way valve is formed in the shape of a spiral leaf spring, and the fluid flow interference caused when the one-way valve is opened is minimized, so that it can reduce noise and increase fluid efficiency.

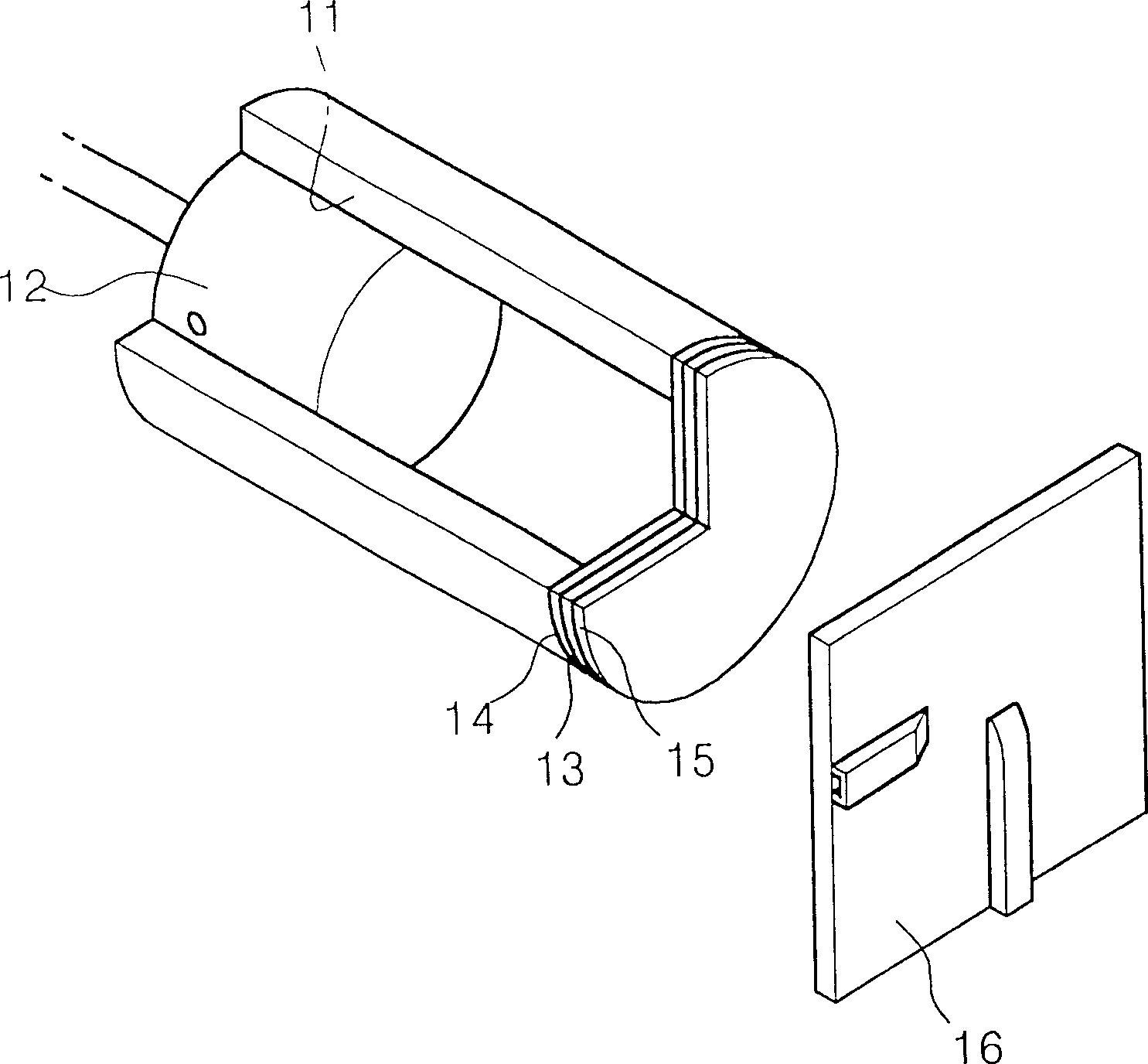

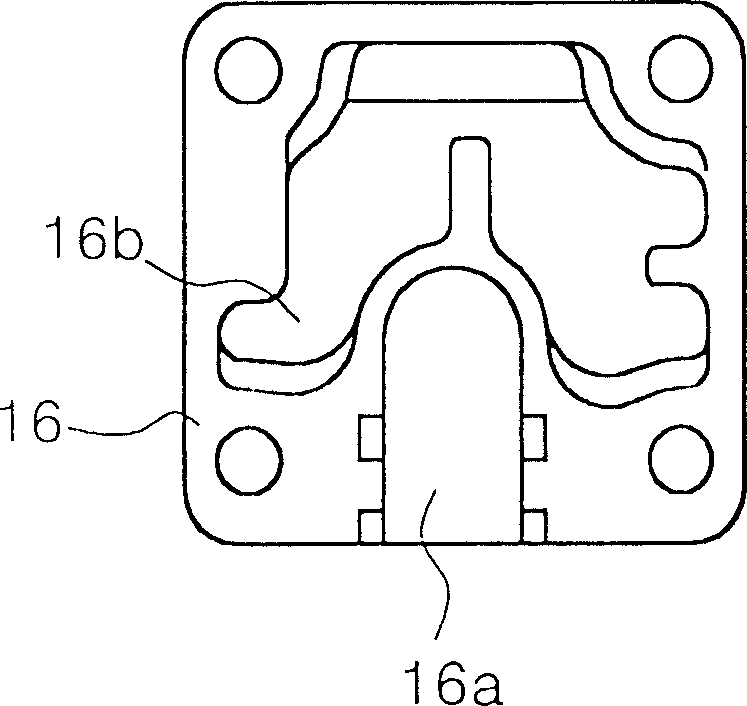

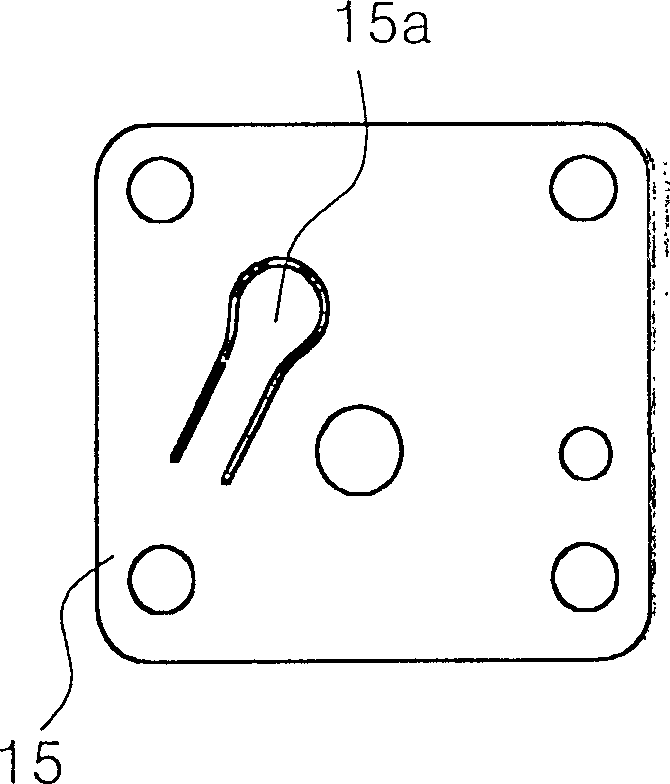

[0037] The preferred embodiments shown in the drawings will be described in detail below. Similar symbols in the figures indicate corresponding components.

[0038] Fig. 4 is a structural diagram of a one-way valve of a preferred embodiment of the present invention.

[0039] As shown in Figure 4, the one-way valve of the present invention is formed as a spiral leaf spring 20, so that when the fluid flows in one direction, because the parts of the device are partially overlapped and compressed, the fluid flow is prevented; and when the fluid flows in the other direction At this time, the valve stretches open to promote fluid flow.

[0040] Fig. 5 shows the operation of the check valve of the above-mentioned structure.

[0041] Fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap