Continuous underground wall constructing method with linked tubular pile and its special linked tubular pile hole former

An underground diaphragm wall and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in stabilizing trench walls, constructing underground diaphragm walls, and multiplying investment, and achieves low sinking resistance , good anti-seepage effect and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

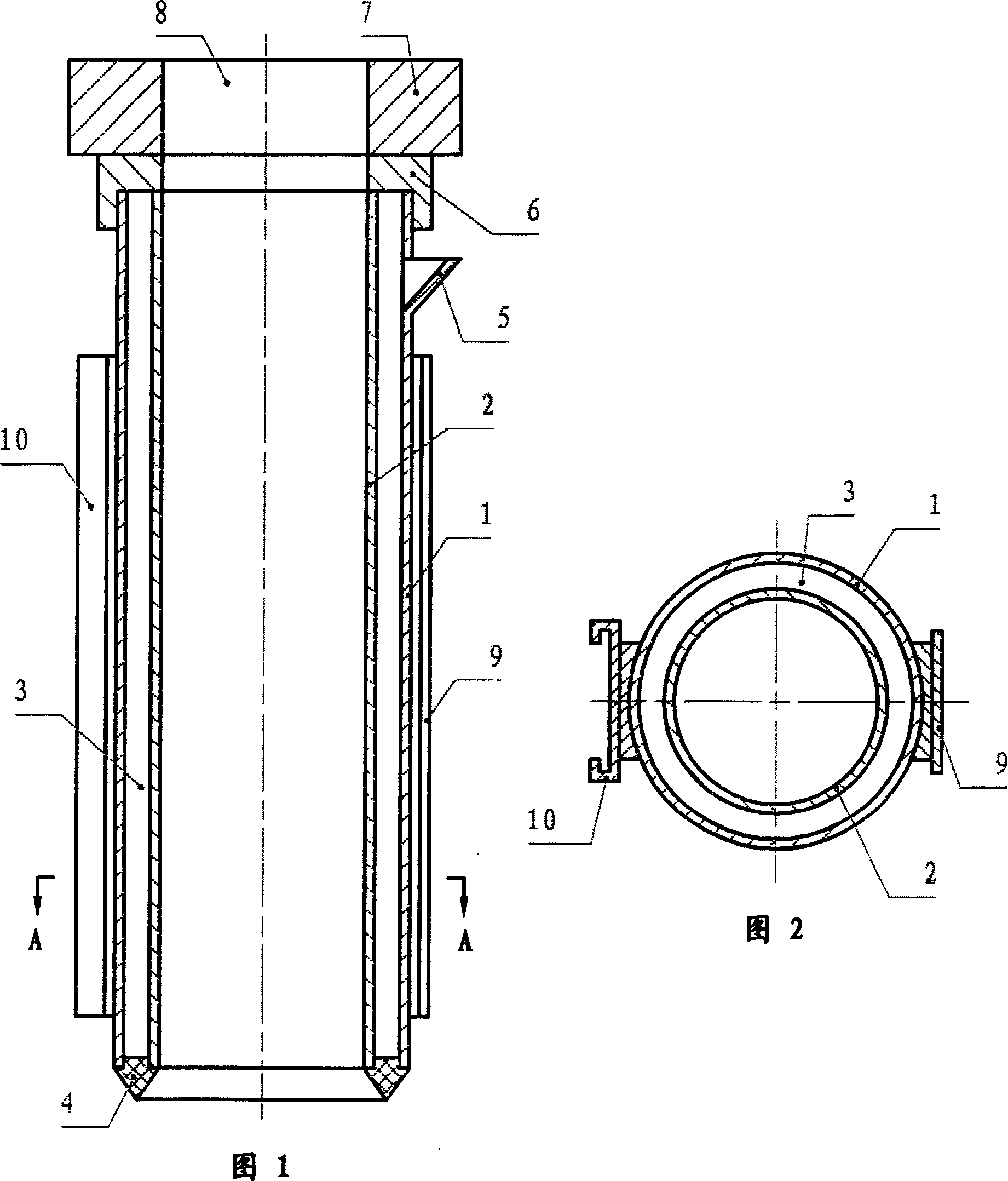

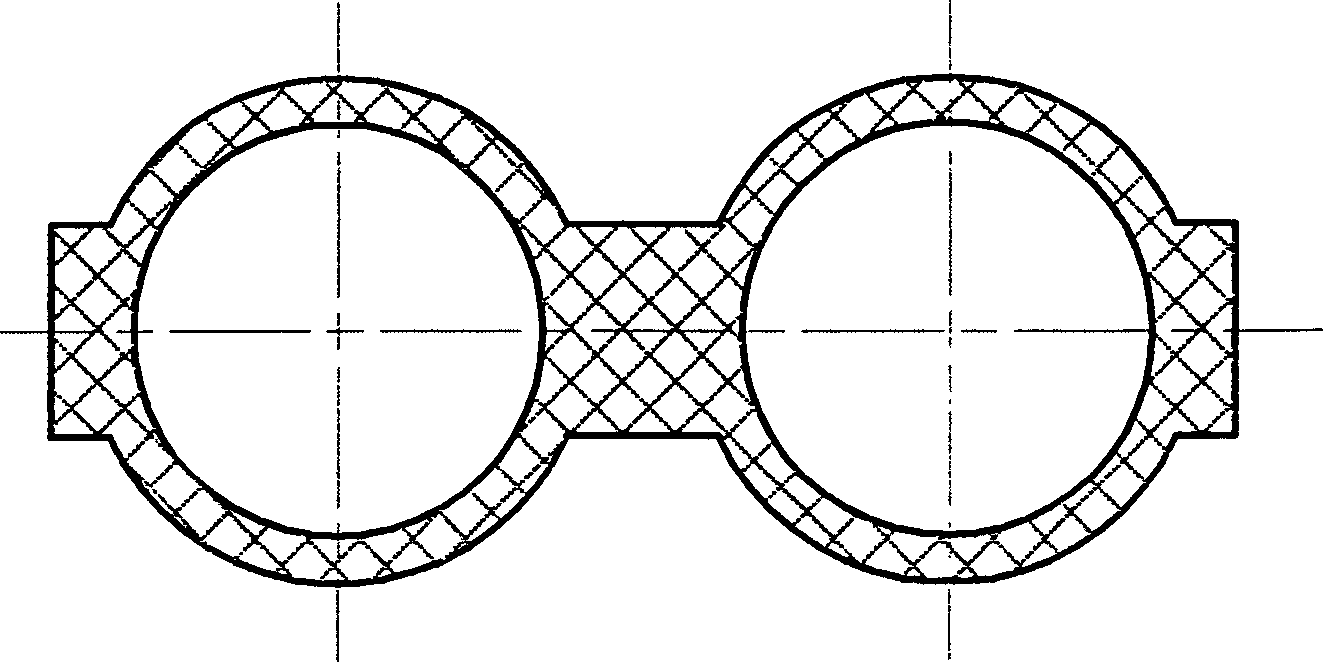

[0020] The essence of the implementation method of the present invention is to combine the cast-in-place concrete tubular piles into one body to form an underground continuous wall by using the jointed tubular pile hole forming device with male and female guides. The method is as follows:

[0021] (A) Install ring-shaped supporting pile shoes 4 with cutting surfaces at the bottom of the cylinder cavity 3 of all combined cylinder pile hole formers;

[0022] (B) Place the first combined tube pile hole forming device upright at the construction position and apply pressure on the vibrating head 7, so that the combined tube pile hole forming device sinks to the soft soil layer at the design depth, and the displaced soil Discharge from the mud outlet 8 of the conjoined barrel pile hole forming device;

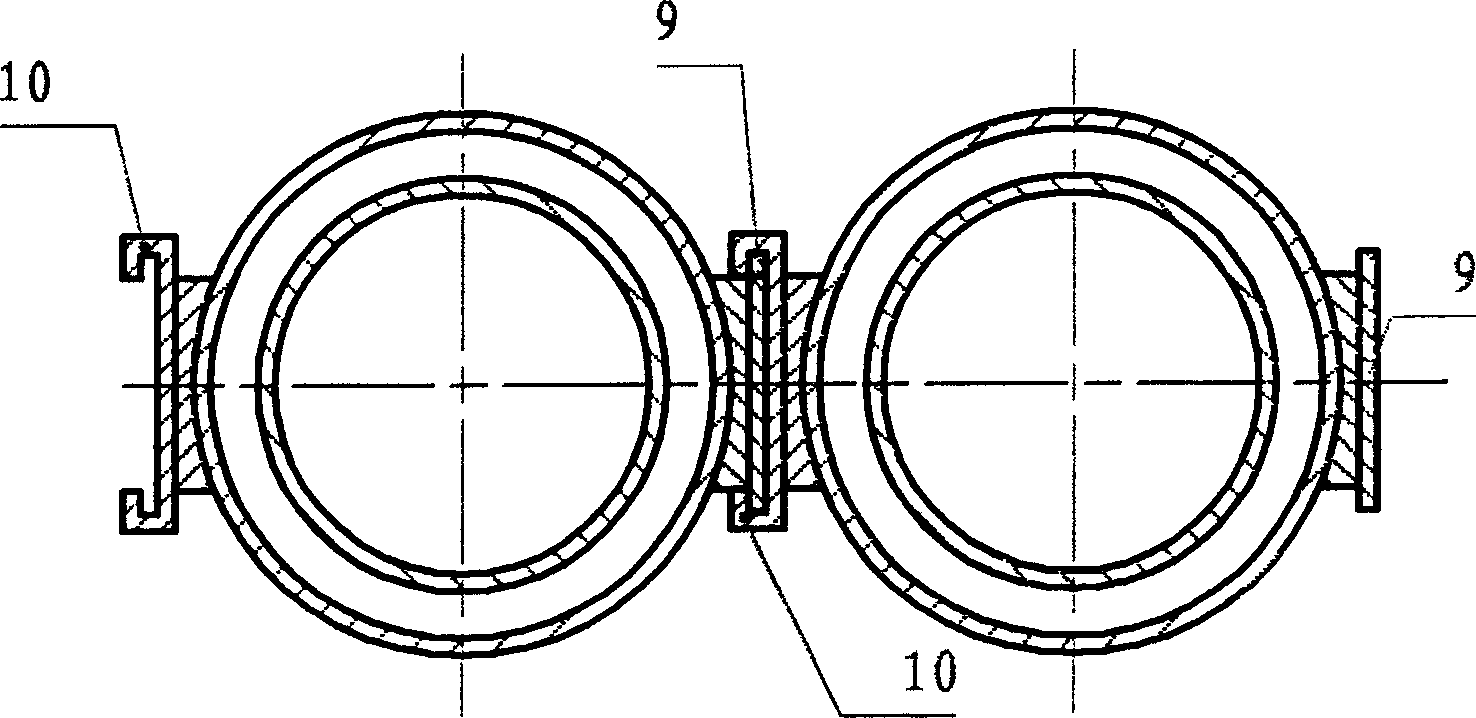

[0023] (C) Connect and position the male connector 9 on the second conjoined cylindrical pile hole former with the female connector 10 of the first conjoined cylindrical pile hole fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com