Virtual positioning method for optical multiple-parameter measurement

A technology of parameter measurement and positioning method, which is applied in the field of virtual positioning, can solve problems such as complex body shapes, and achieve the effect of rapid adjustment and high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

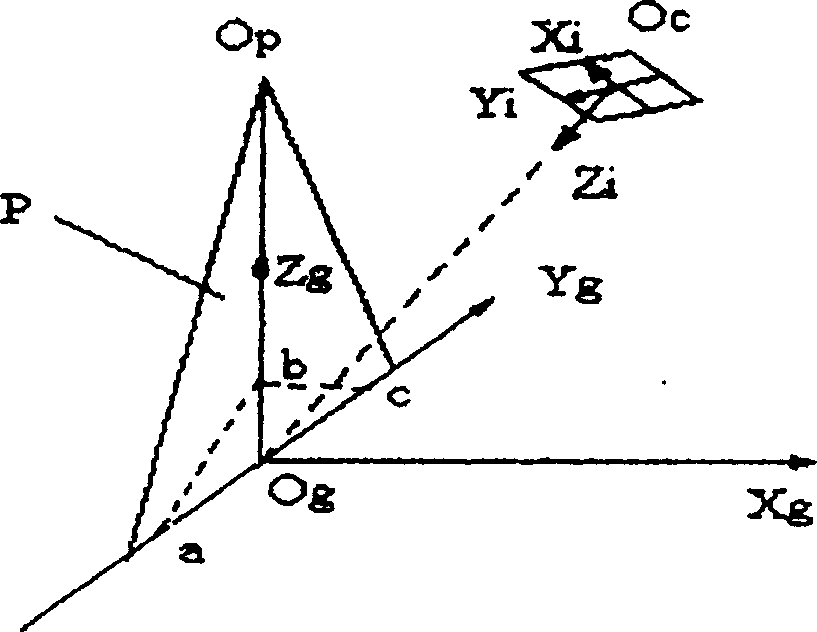

[0014] In the present invention, according to the measurement principle of the two-dimensional vision sensor, its imaging formula is given. This formula is a mathematical expression for mapping the Yg-Zg plane coordinates of the object space to the Xi-Yi coordinates of the image plane:

[0015]

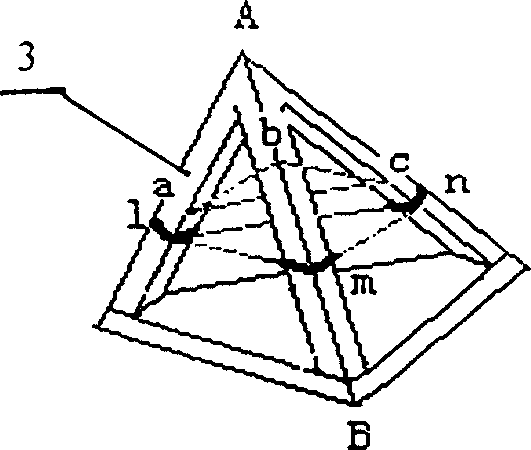

[0016] for figure 1 In the line structured light model shown in , if a triangle Δabc is imagined on the object space Yg-Zg plane, then a corresponding triangle Δa'b'c' is virtualized on the image plane Xi-Yi through formula calculation. The virtual positioning technology uses this principle to virtualize the ideal position (ideal triangle) of the regular tetrahedron in space on the image plane of the two-dimensional vision sensor corresponding to the two-dimensional vision sensor, and displays the ideal triangle on the computer screen. Draw on it and let it stay fixed.

[0017] The realization of the ideal triangle Δabc in the present invention is obtained by measuring and calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com