Temperature adjusting and controlling method for minitype experiment period and special apparatus therefor

An experimental section, miniature technology, applied in the field of temperature adjustment and temperature control, can solve the problems of large energy consumption, low temperature control accuracy, and long time required to achieve fast temperature adjustment speed, wide temperature adjustment range, and high temperature control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

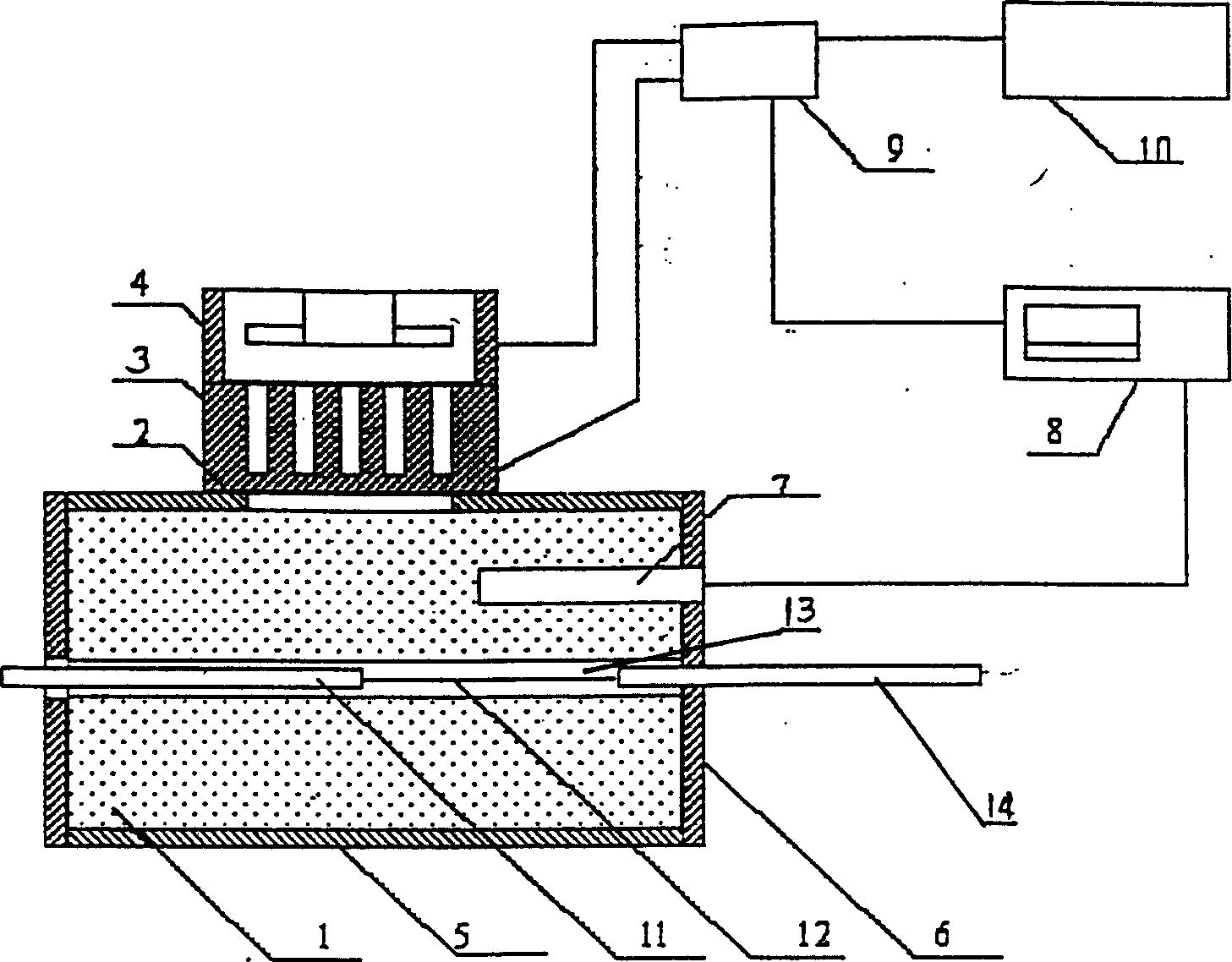

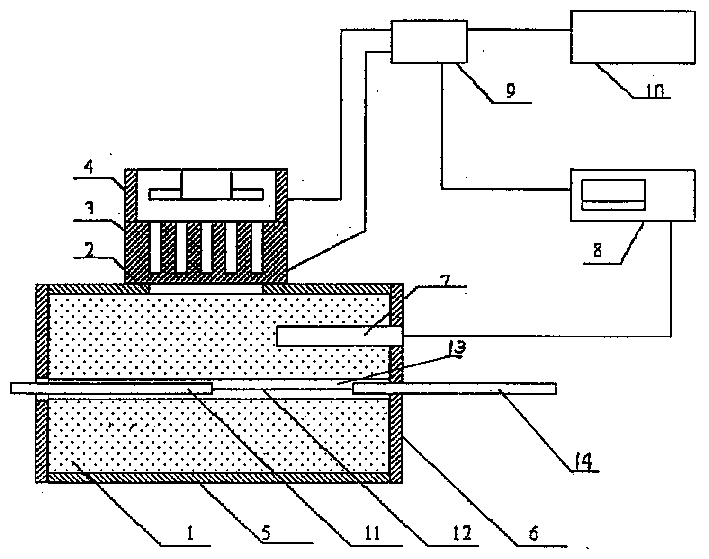

[0021] Attached figure 1 Make a device suitable for temperature regulation and temperature control in the micro-experiment section, take a rectangular copper plate with a length of 180mm as the metal body 1, and its cross-sectional area is 50mm×50mm; punch a hole with a diameter of 4mm in the middle along the long side direction as the metal body 1. Place the experimental section flow channel 13 of the experimental section, insert a pre-cooling / heating pipe 11 in the experimental section flow channel 13, and the front end of the tube is exposed outside the metal body 1, and the end is connected with a diameter of 0.1mm-4mm for the experiment The capillary tubes 12 are connected, and the rear end of the capillary tube is connected with a glass tube 14 for metering. A flat semiconductor cooler 2 is installed between the top of the metal body 1 and the radiator 3 with fins, or a cooling fan 4 can also be installed on the radiator 3 . The metal body 1 is covered with thermal insu...

Embodiment 2

[0023] On the device of embodiment 1, a flat semiconductor refrigerator 2 is adorned on the bottom surface of metal body 1 again; Radiator fin outside is equipped with cooling fan 4, and temperature sensor 7 is contained in the hole that is opened on metal body 1, The conventional temperature control instrument 8 controls the switching direction and switching time of the DC power supply 10 through the temperature control circuit 9 . When the temperature of the metal body 1 is higher than the set temperature of the temperature control instrument 8, the side of the semiconductor refrigerator 2 attached to the metal body 1 is the cold end, and the side close to the radiator is the hot end. The body 1 cools down; when the temperature of the metal body 1 is lower than the set temperature, by changing the connection direction of the DC power supply 10, the side of the semiconductor refrigerator 2 attached to the metal body 1 becomes the hot end, thereby heating the metal body 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com