Helical antenna manufacturing apparatus and method thereof

A technology for helical antennas, manufacturing devices, applied in the direction of helical antennas, antenna supports/mounting devices, antennas, etc., capable of solving problems such as low antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following detailed description, preferred embodiments of the invention are shown and described simply by way of illustration of the best mode contemplated by the inventors for carrying out the invention. It should be understood that the present invention is capable of various modifications without departing from the scope of the present invention. Accordingly, the drawings and description are to be regarded as illustrative rather than restrictive.

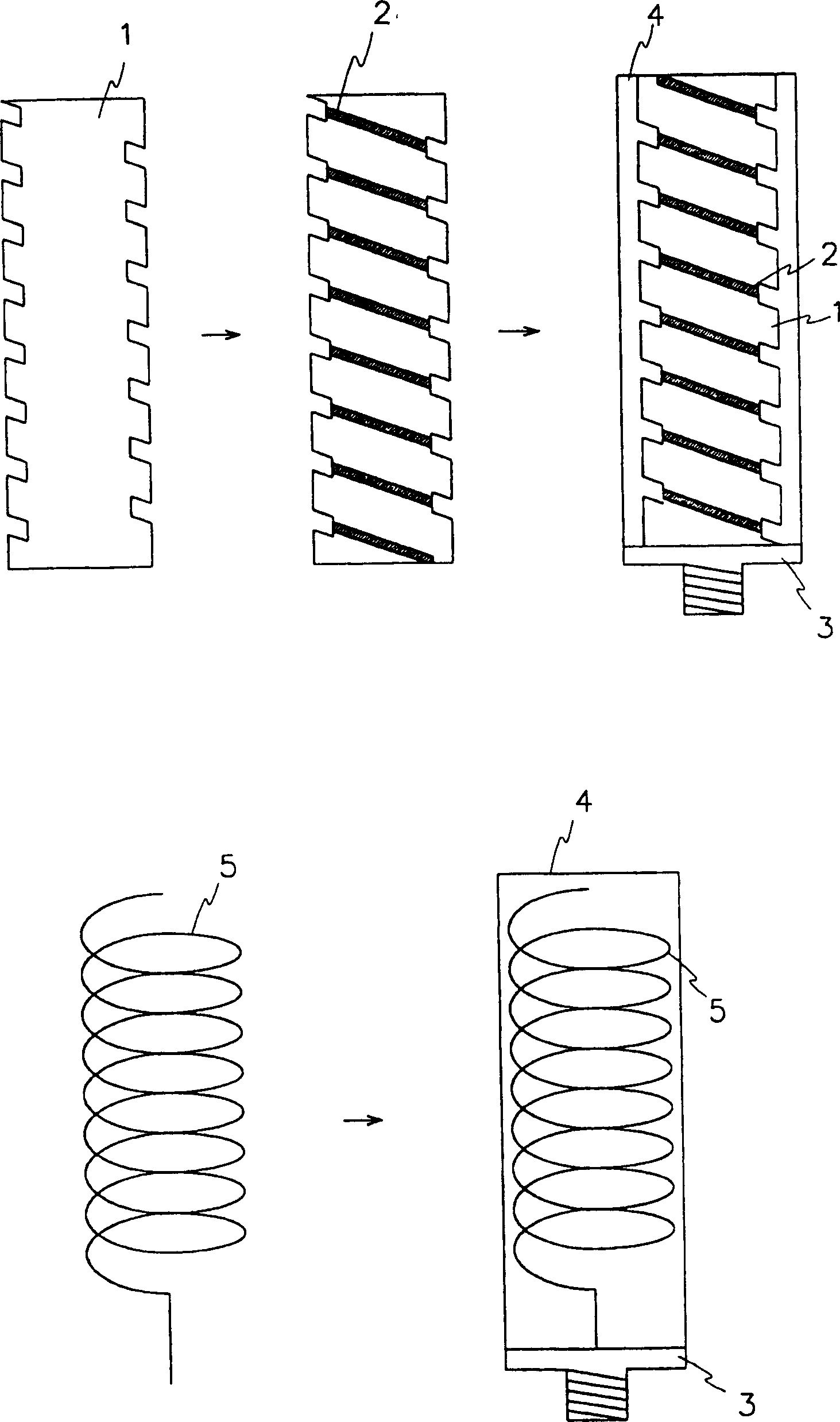

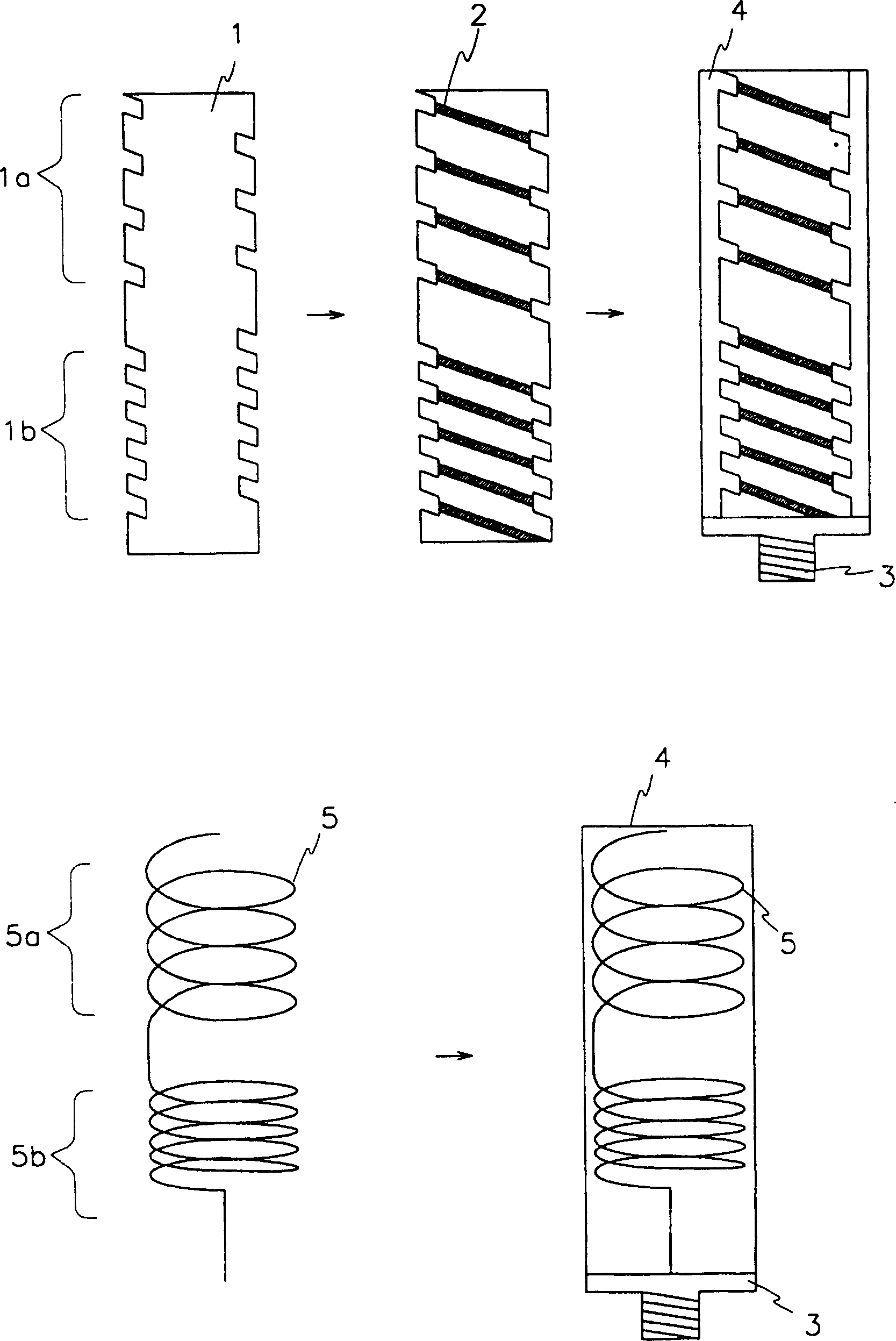

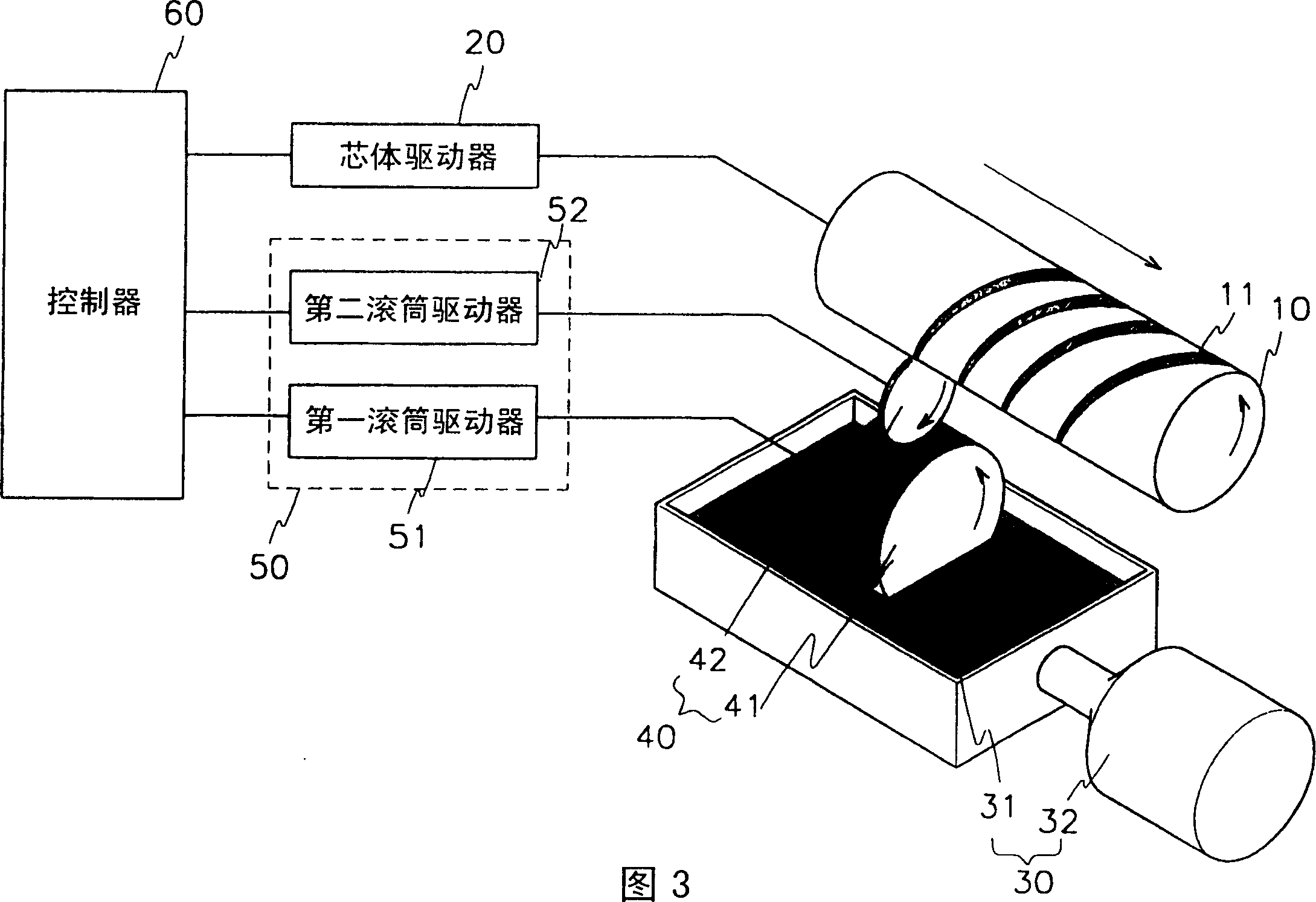

[0062] Fig. 3 shows a schematic diagram of a helical antenna manufacturing apparatus according to a preferred embodiment of the present invention. Figure 4 A detailed schematic diagram of the helical antenna manufacturing apparatus shown in FIG. 3 is shown.

[0063] As shown in Figure 3, according to the helical antenna manufacture device of the first preferred embodiment of the present invention comprises core body 10; The core body driver 20 of rotating core body 10; Provide the adhesive glue provider 30 of conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com