Heater for preventing carburetor from icing up

A carburetor and heater technology, applied to carburetors, machines/engines, engine components, etc., can solve the problems of increased assembly operation steps, increased number of parts, poor performance, etc., so as to suppress fuel evaporation and prevent icing , the effect of inhibiting icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

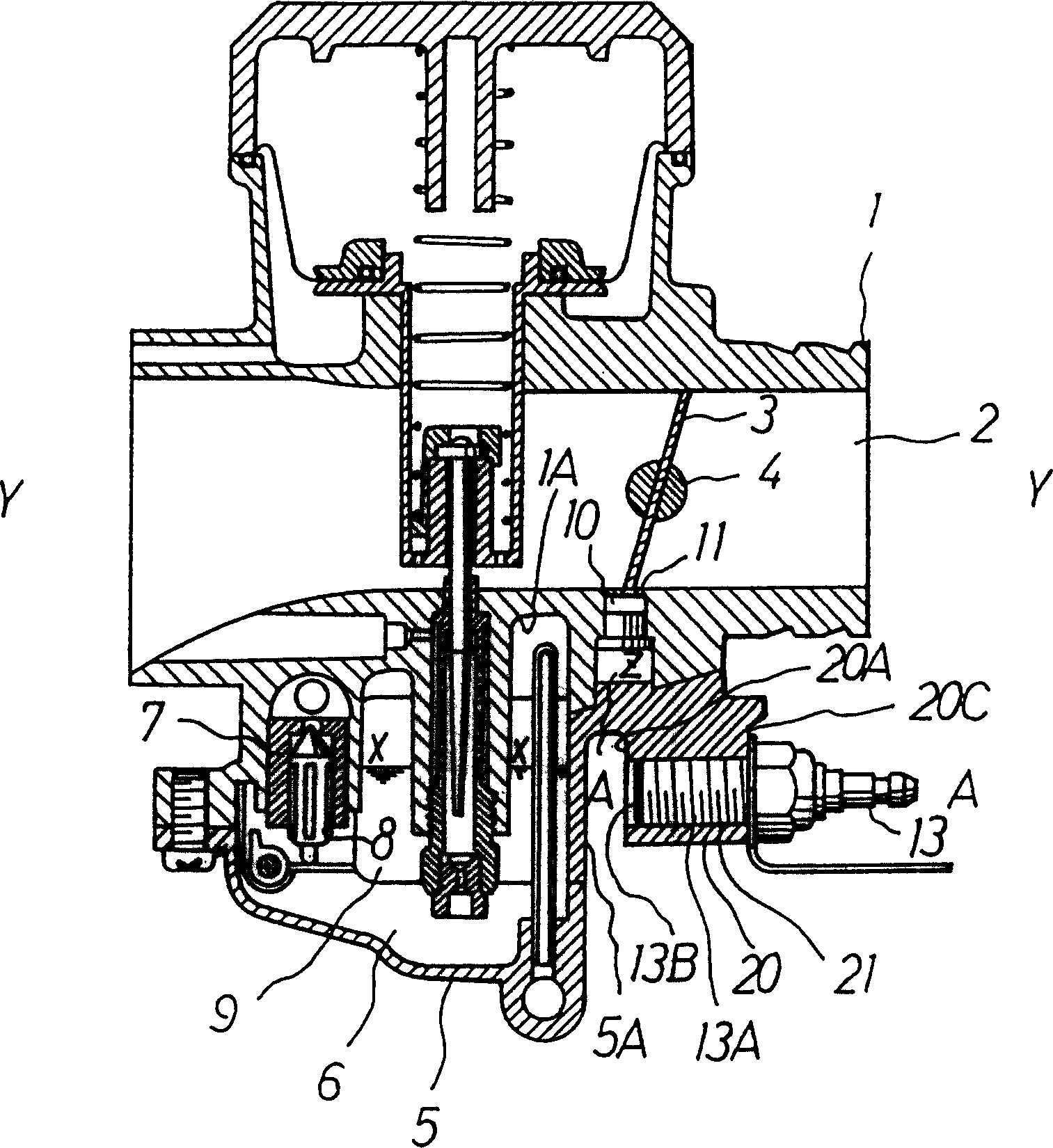

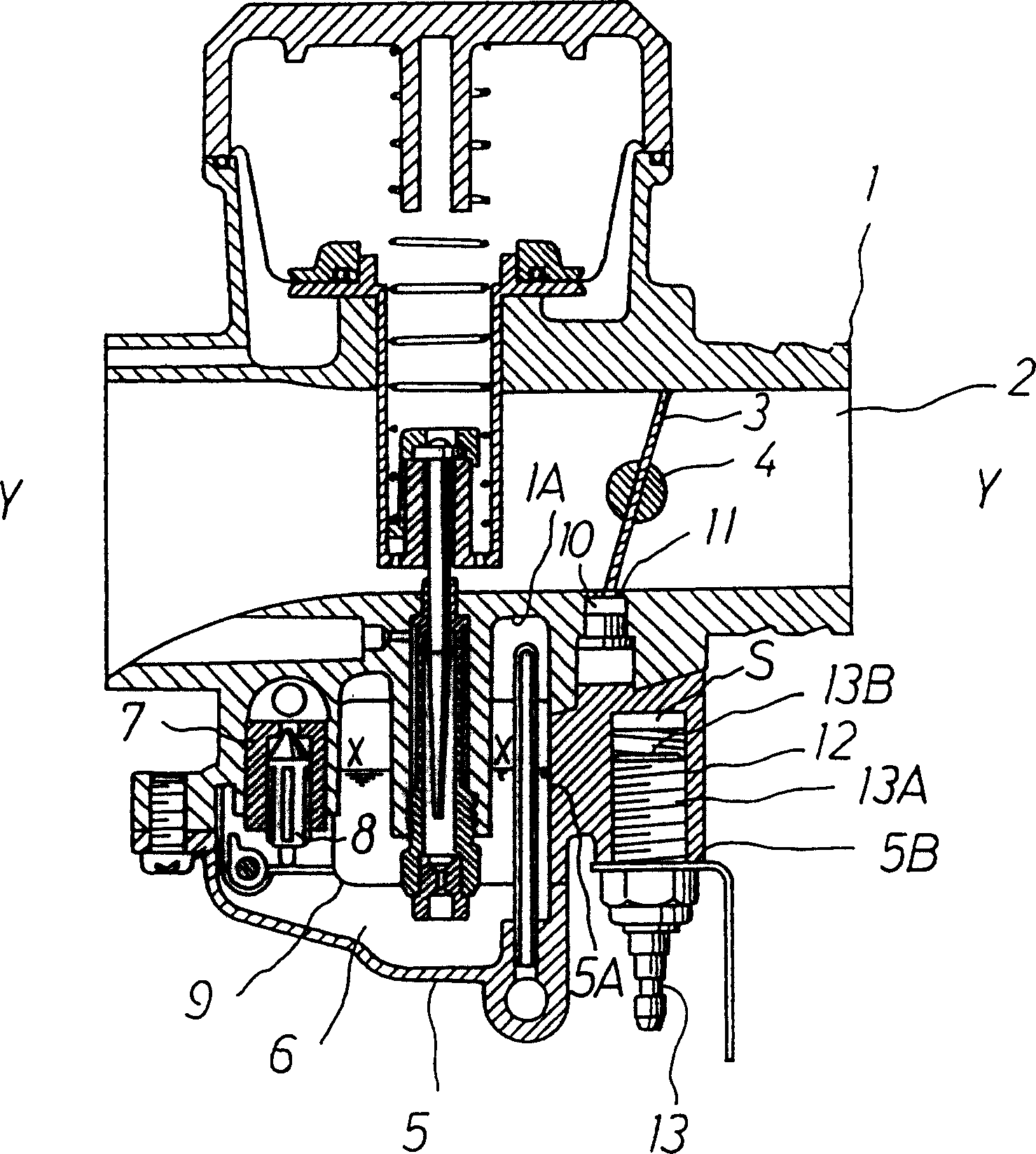

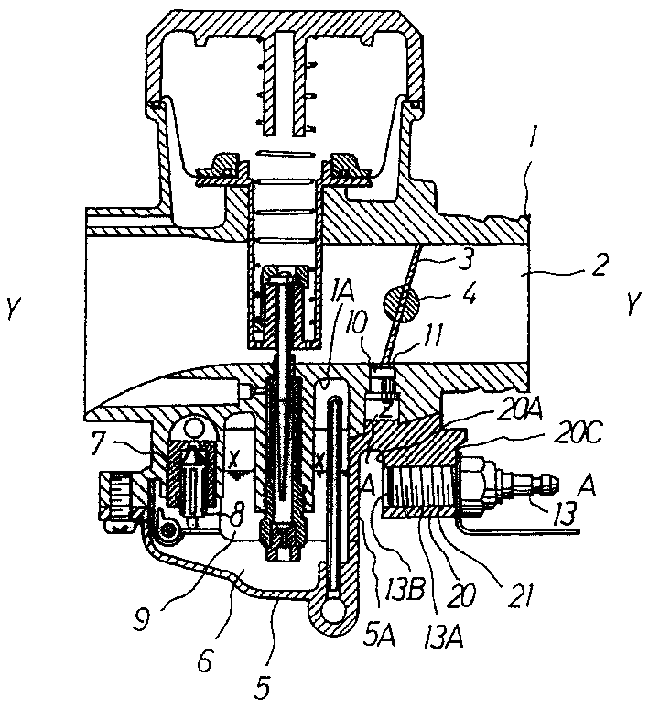

[0032] Below, according to figure 1 One of the anti-freezing heaters of the carburetor of the present invention is explained

[0033] Example.

[0034] for with figure 2 The same symbols are used for the same structural parts, and descriptions are omitted.

[0035] 20 is a heater mounting seat integrally formed with the float chamber main body 5, and the heater mounting seat 20 is formed parallel to the long axis Y-Y of the suction passage 2 and the fuel liquid level X-X in the float chamber.

[0036] Furthermore, a space Z is formed between the front end portion 20A of the heater mount 20 and the side wall 5A of the float chamber main body 5 .

[0037] Further, in this heater mounting base 20 , a heater mounting hole 21 is perforated from the rear end portion 20C toward the front end portion 20A, and a female thread is formed therein.

[0038] The heater mounting hole 21 is preferably formed as close to the bypass chamber 10 as possible.

[0039] Furthermore, the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com