Sliding slot heat treatment device

A heat treatment device and heat treatment chamber technology, applied in lighting and heating equipment, furnace components, furnace types, etc., can solve the problems of high heat treatment device height and hot gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

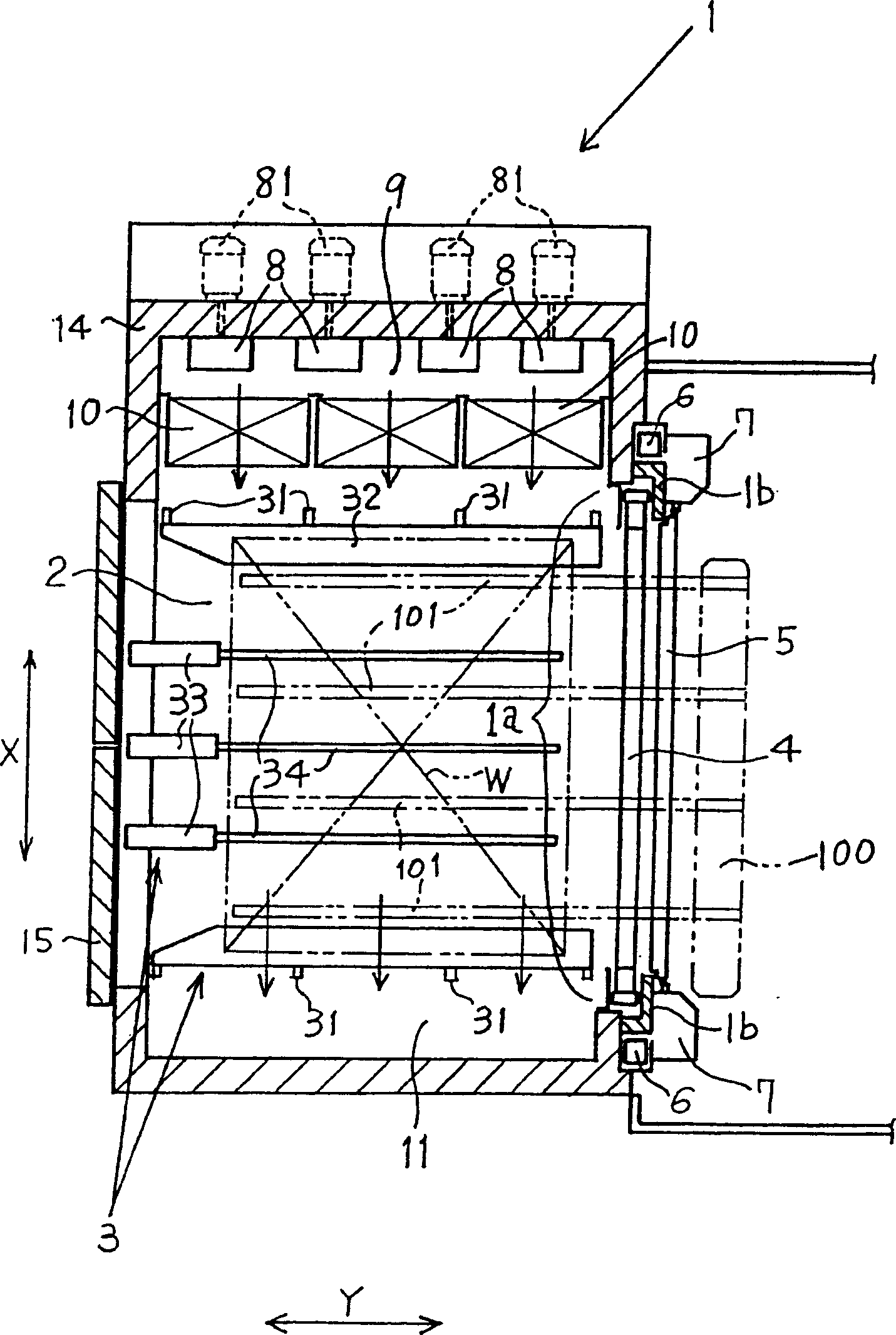

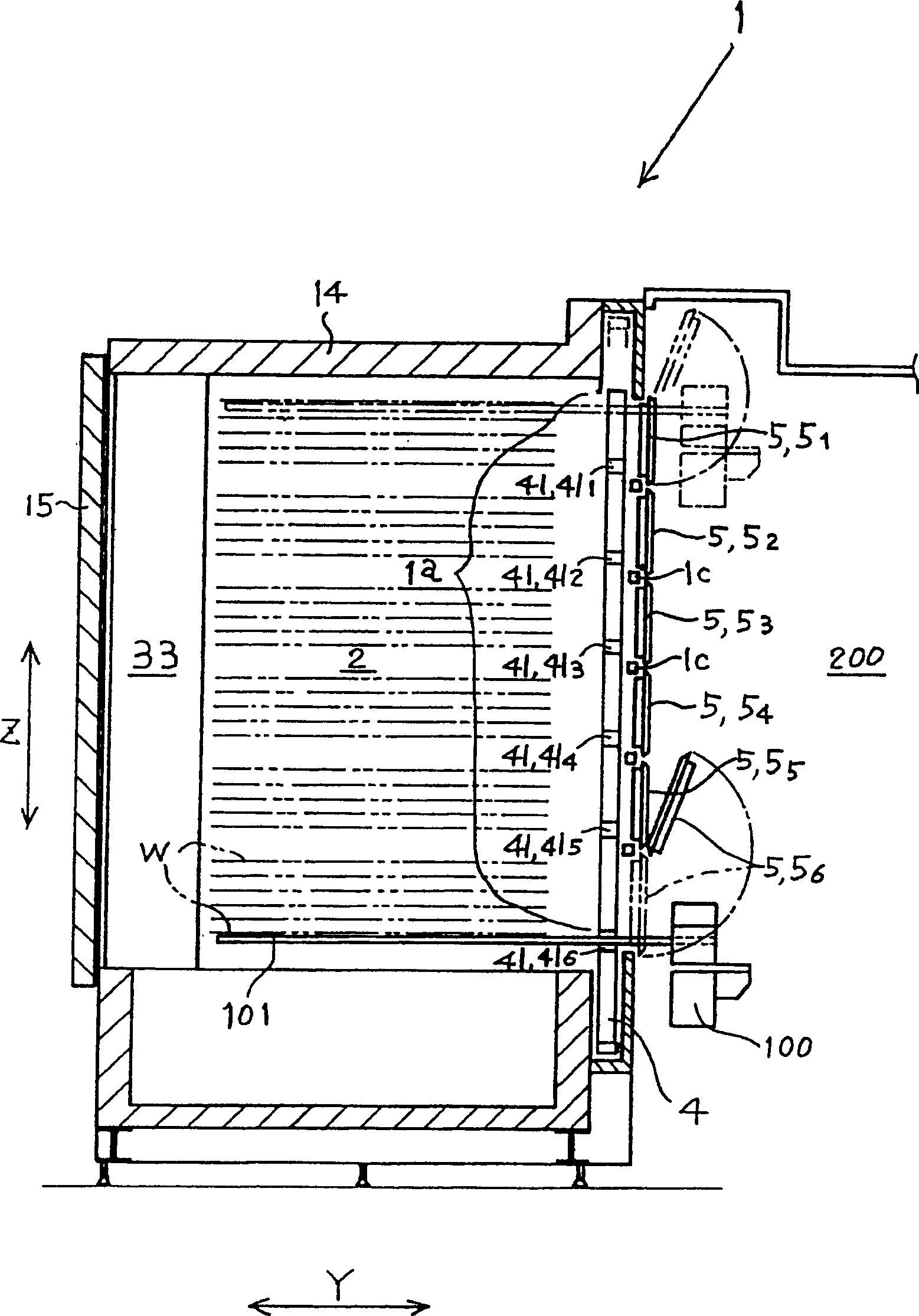

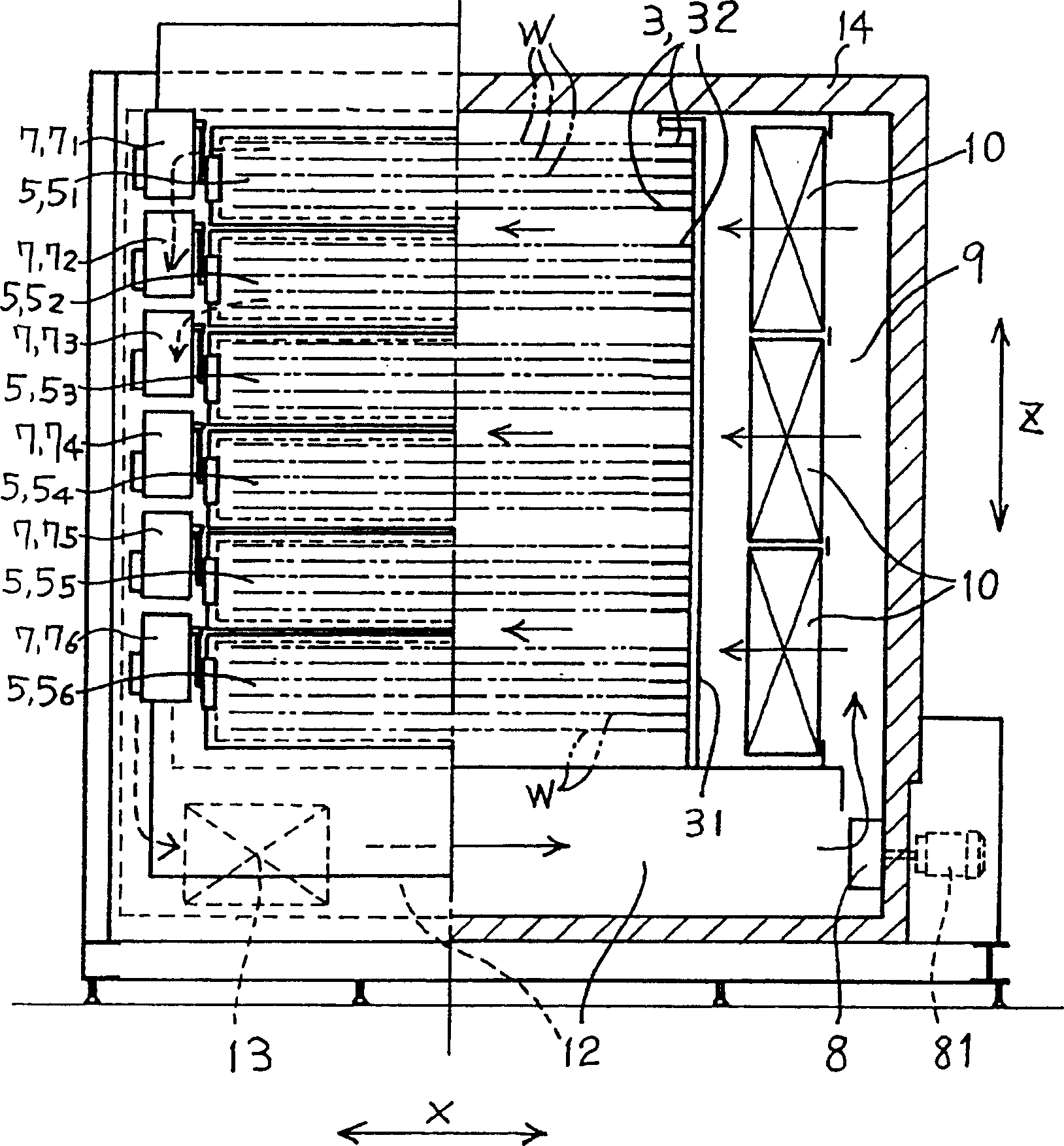

[0030] Figure 1 ~ Figure 3 An example of the overall structure of a heat treatment apparatus commonly called a purification furnace as a heat treatment apparatus to which the present invention is applied is shown.

[0031] The heat treatment apparatus 1 is a kind of workpiece W such as a glass substrate that is processed in a LCD substrate or a PDP manufacturing flow as a flat plate-shaped object to be processed with a support body 3 as a support device installed in the heat treatment chamber 2. , and from the opening face 1a that is formed on one side of the heat treatment chamber as the opening of the heat treatment chamber 2 in this example to take and place the device for heat treatment one by one, wherein as a multilayer, it is 31 layers in this example, and it has as a slit The shielding plate 4, the small door 5, the lifting mechanism 6, and the opening and closing mechanism 7 of the parts.

[0032] There are air-conditioning parts on both sides of the width X directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com