Connector for printed circuit board

A technology for printed circuit boards and connectors, applied in the field of connectors, can solve the problems of increasing manufacturing costs, increasing the number of components, and complex inventory control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

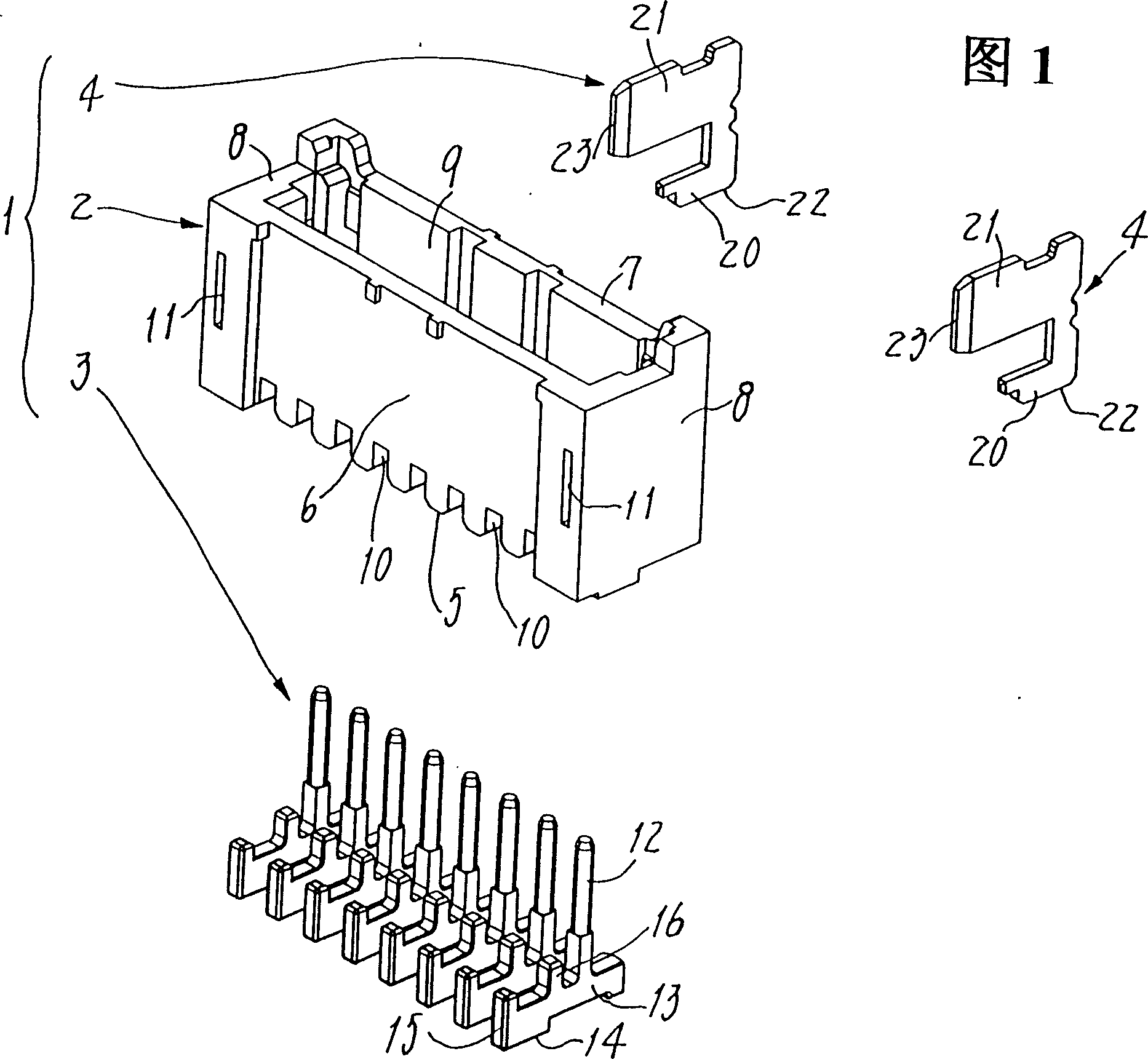

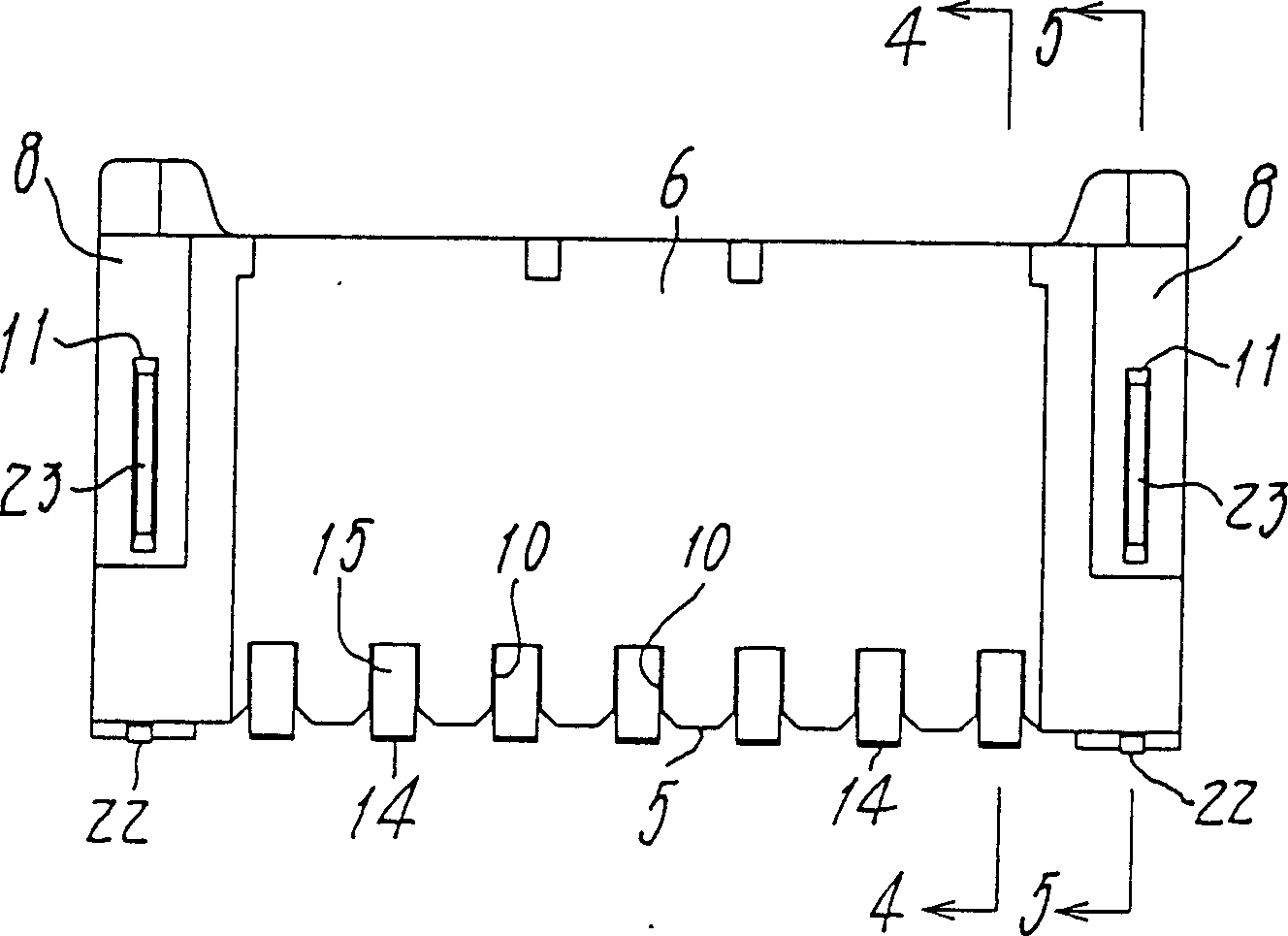

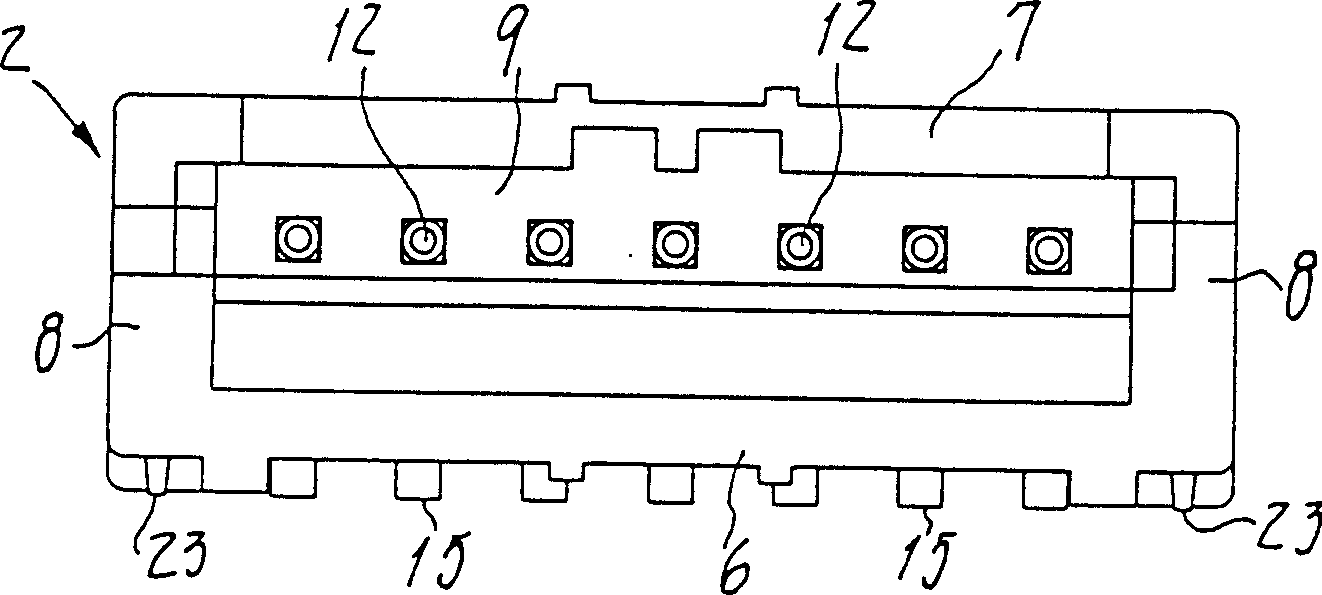

[0032] Some preferred embodiments of the invention will now be described with reference to the accompanying drawings.

[0033] 1 to 5 show a connector 1 provided here as a plug for a printed circuit board. The connector 1 has an insulating shell 2, a row of contacts 3 kept at a regular interval in the shell, and reinforcing metal sheets 4 fixed on both sides of the shell.

[0034] The casing 2 is an elongated box made of insulating material and has an opening facing upward. The opening in the box is defined between the bottom 5 , the front wall 6 , the rear wall 7 and the opposite side walls 8 and 8 . The open top 9 of the housing serves as a spout for a mating connector (not shown). Slot-shaped cutouts 10 are formed in the bottom 5 at constant intervals to engage with the contacts 3 respectively. Apertures 11 and 11 are formed in the side wall 8 to receive and fixedly retain the respective reinforcement metal 4 therein.

[0035] The contacts 3 are manufactured by punching...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap