Ink jet recording method, ink set, and recorded matter using them

An inkjet recording method and technology for recording media, which are applied in the directions of inks, applications, household appliances, etc., can solve problems such as inability to place transparent resins, increase in cost, and enlargement of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] (1) Modulation ink set

[0153] An ink composition composed of the following components was prepared as an ink set. Each ink composition was prepared in the following order. That is, the pigment, dispersant and water are mixed, placed in a sand mill (manufactured by Yaskawa), and dispersed with glass beads [diameter=1.7mm; dosage: 1.5 times (weight) of the mixture] for two hours, and then Take out the glass microspheres and prepare a pigment dispersion.

[0154] Next, mixing ingredients other than the pigment and the dispersant as an ink solvent, and while stirring the above-mentioned pigment dispersion liquid, the above-mentioned ink solvent was slowly added dropwise, and stirred at room temperature for 20 minutes. It was filtered through a 5 μm membrane filter to prepare an ink composition for inkjet recording.

[0155] The compounding components of each ink composition are shown below.

[0156] (a) Black ink composition

[0157] Carbon black MA7 (Mitsubishi Chem...

Embodiment 2

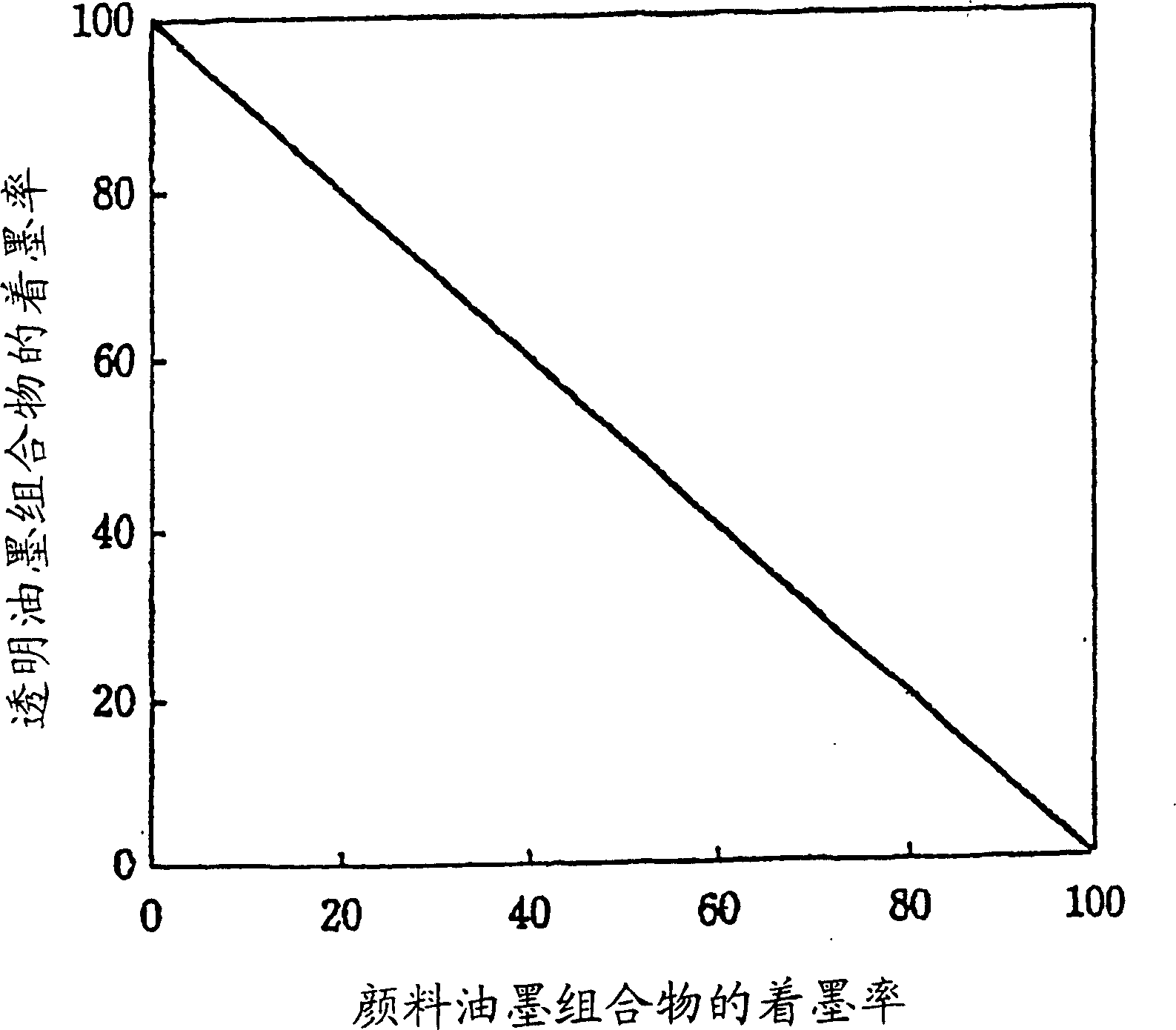

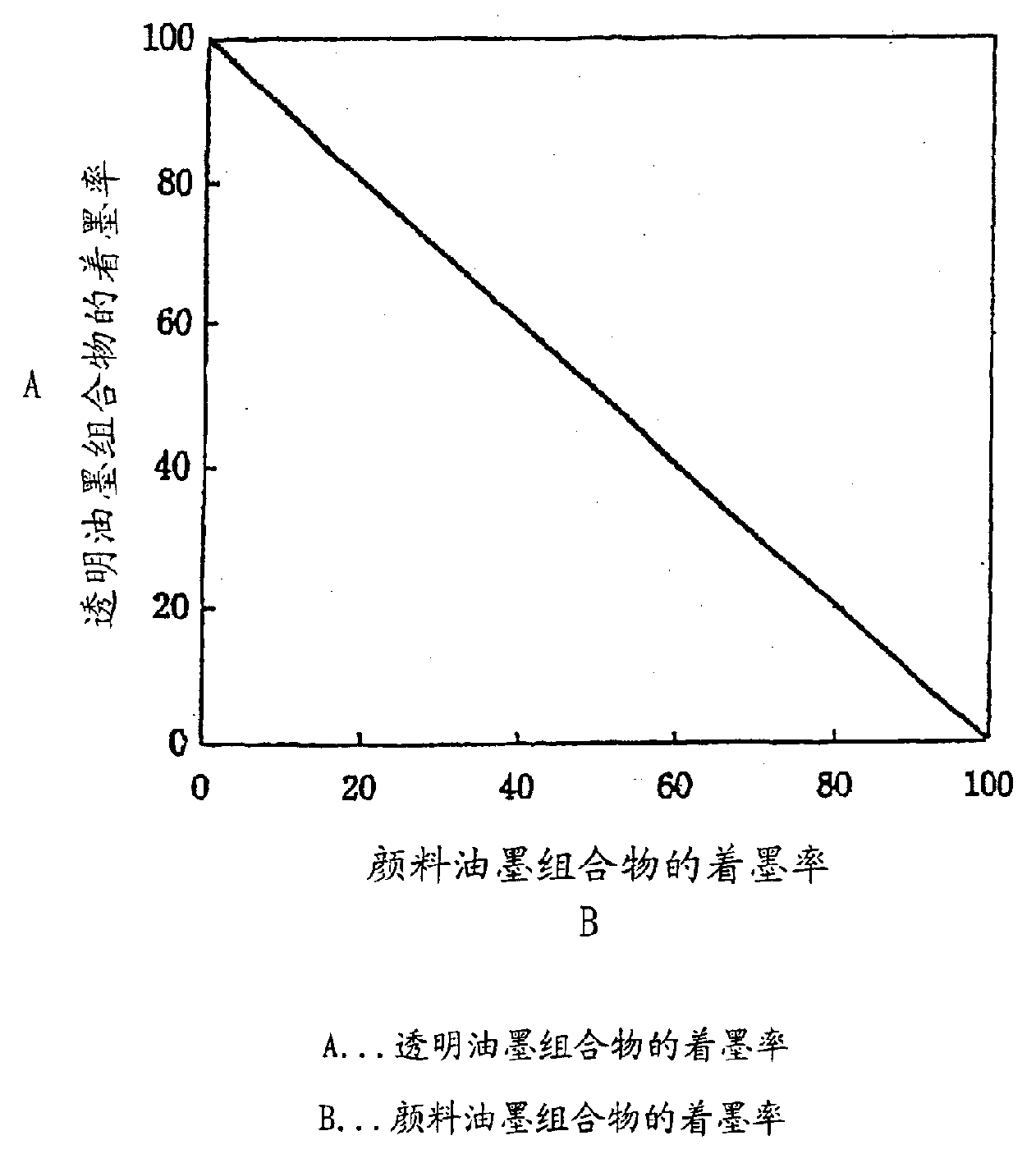

[0213] In an inkjet printer (PM-770C; manufactured by Seiko Epson Co., Ltd.), an ink cartridge containing five pigment ink compositions (all five colors) and one clear ink composition composed as shown below was installed. Adjust the ejection amount of the transparent ink so that when the ink coverage of the pigment ink composition is low, increase the ejection amount of the transparent ink composition; when the ink coverage of the pigment ink composition is high, reduce the ejection of the transparent ink composition Specifically, adjust the ink coverage ratios of the two ink compositions to the values (10 modes) shown in Table 4, and form the corresponding ink coverage on the recording medium (dedicated glossy film; manufactured by Seiko Epson Co., Ltd.). rate printed images. In this process, the pigment ink composition and the transparent pigment composition are ejected from the print head to form an image during the same process. The glossiness of the obtained image was...

Embodiment 3 and comparative example 3

[0287] In addition to changing the single-color pigment ink composition to a mixed-color (multiple) pigment ink composition, the recording methods of Example 2 and Comparative Example 2 were used to obtain the gloss ratio. The results are shown below. At this time, as in the case of using a single-color ink composition, when printing, when the ink coverage of the pigment ink composition (all mixed color ink compositions) is high, reduce the ink coverage of the transparent ink composition; when the pigment ink composition When the ink coverage of the transparent ink composition is low, increase the ink coverage of the transparent ink composition. And the gloss ratio at this time is the maximum / minimum value of the gloss when the ink coverage ratio of the printed pigment ink composition is 1:1 (dual-color) or 1:1:1 (three-color) in one pass. value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com