Nail magazine for power nailer

A nail cartridge and nail driving technology, applied in the field of nail cartridges, can solve the problems of expensive, bulky nail driving machine, difficult to use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

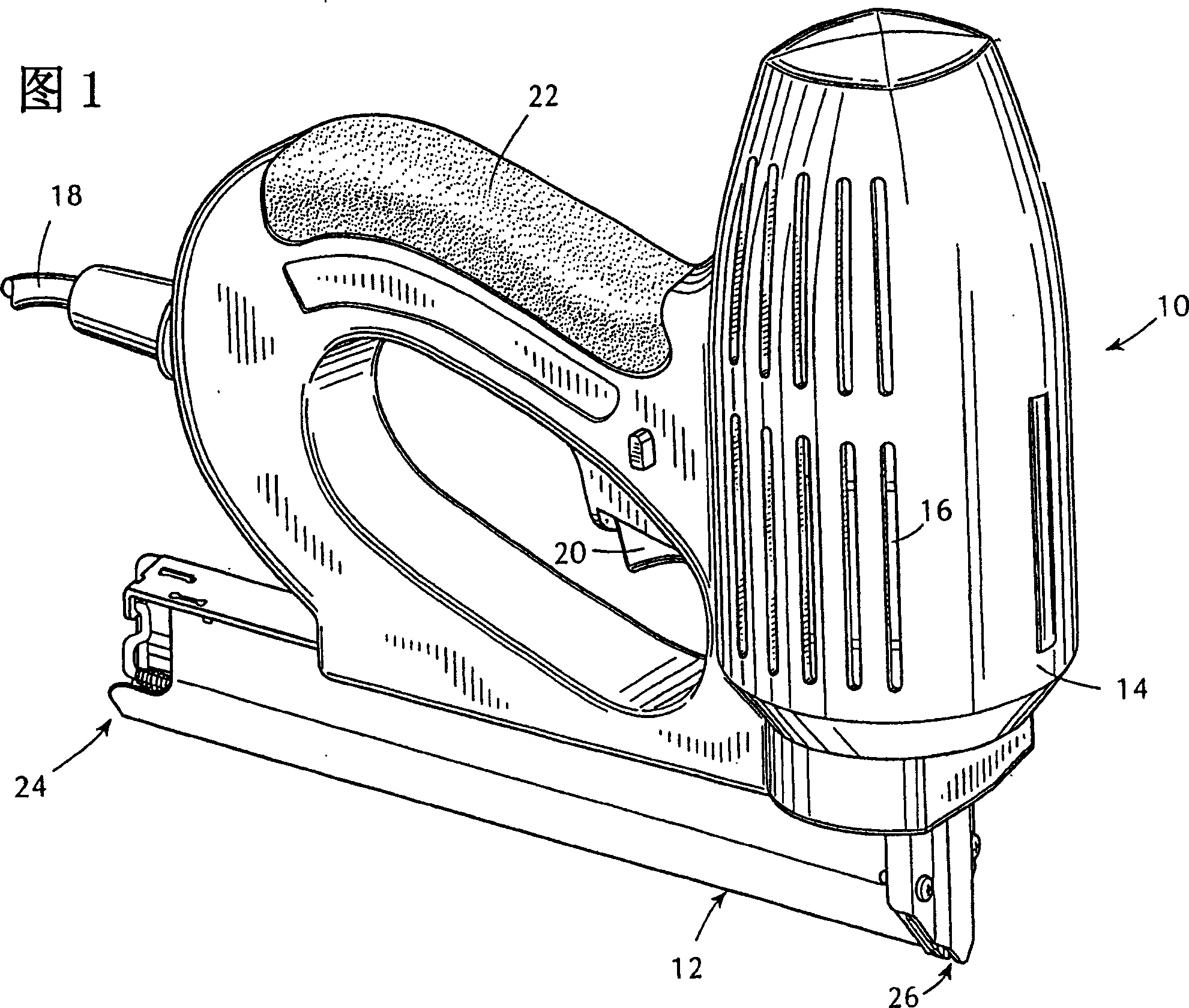

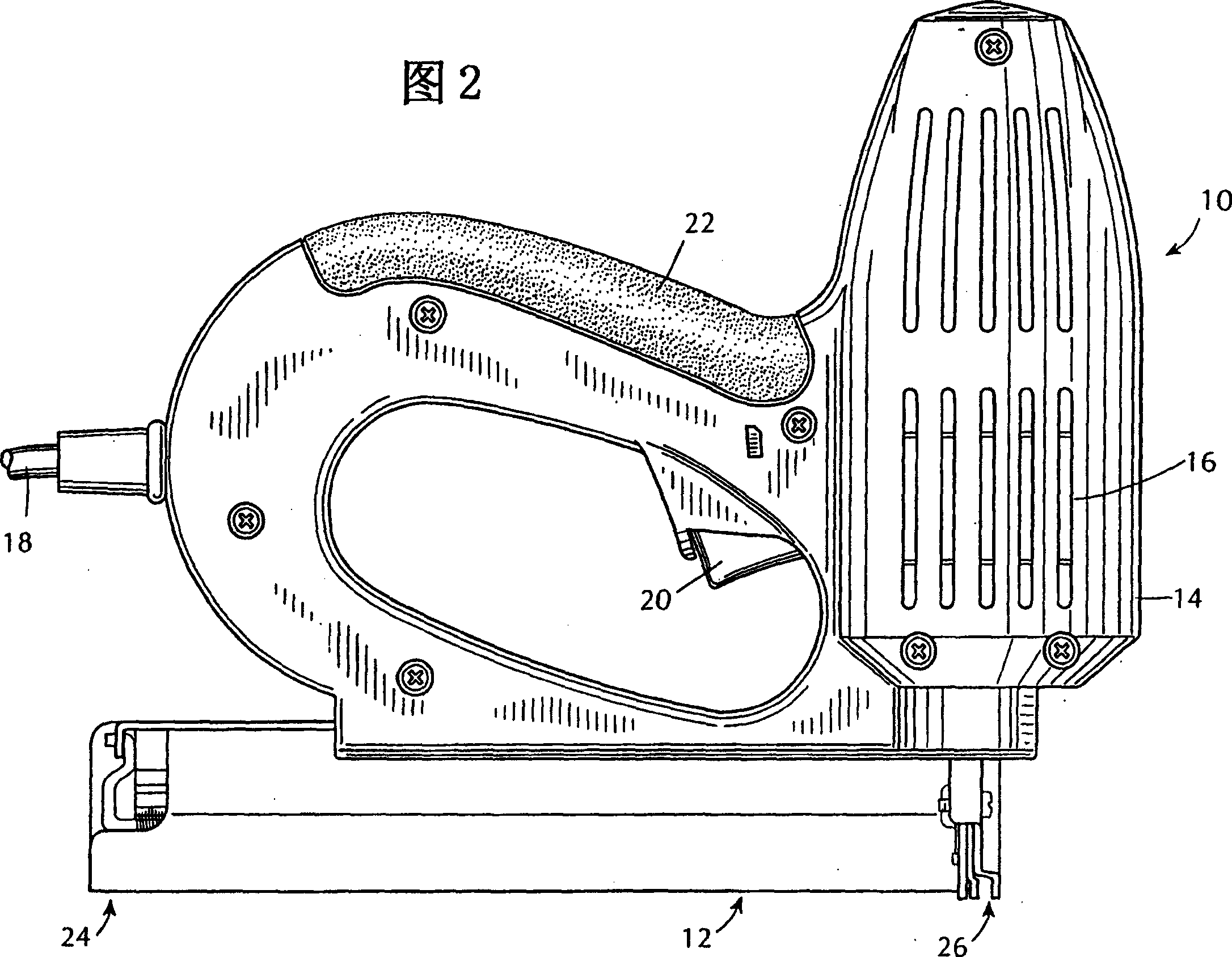

[0017] Referring now to FIG. 1, there is shown an electric nailer 10 incorporating a staple cartridge 12 constructed in accordance with the present invention. The nailer 10 has a housing 14 containing a conventionally constructed drive head 16 therein. Power is supplied to the head 16 from a power supply line 18 . A conventional trigger mechanism (trigger) 20 is provided on the handle 22 for operating the power head and driving the nails within the cartridge 12 . The power head 16 is provided with a solenoid arrangement or electric motor to reciprocate a hammer or so-called "machete" in known manner, acting on top of the nails in the magazine 12 to drive the nails into the workpiece.

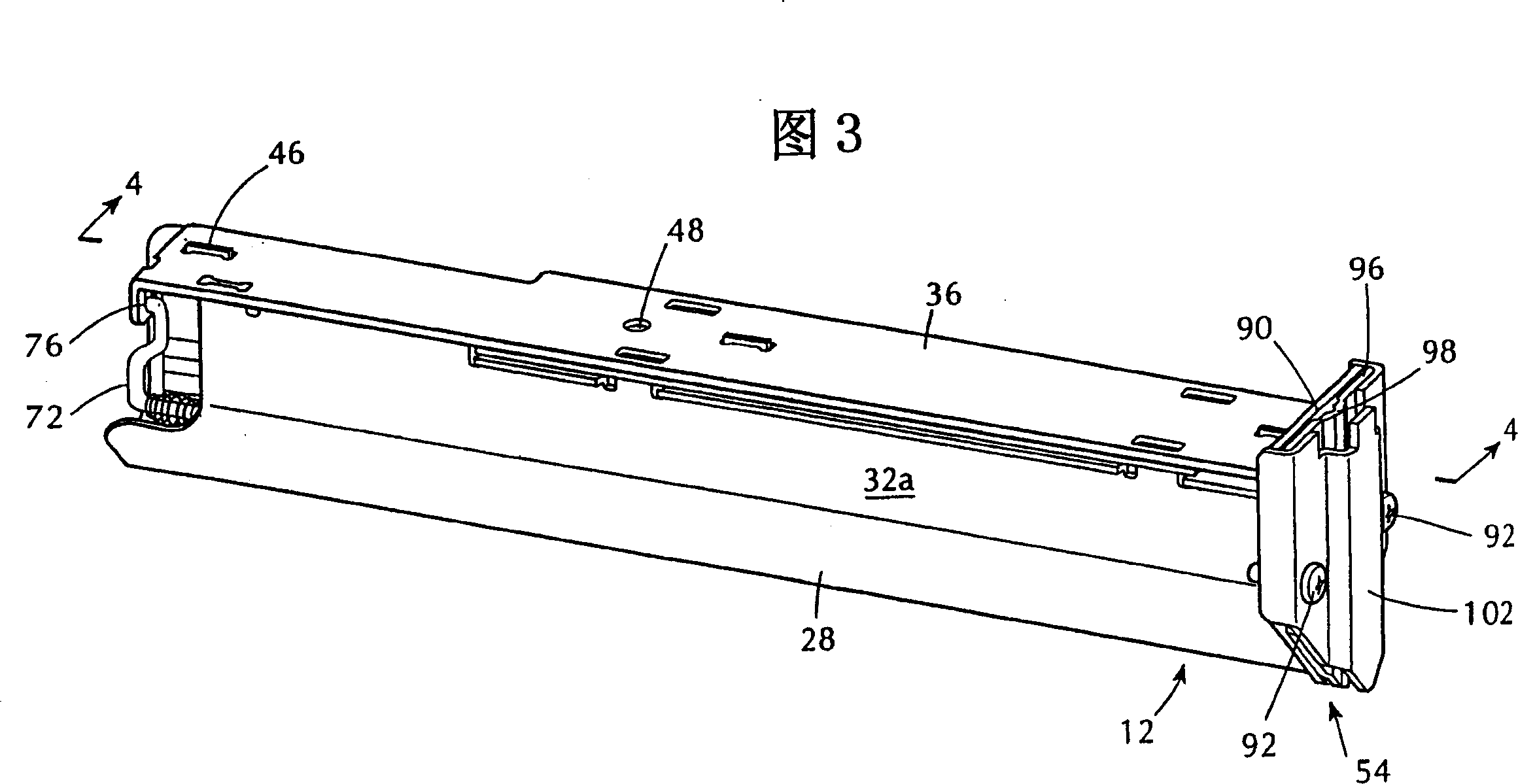

[0018] The staple cartridge 12 has a staple loading rear end and a front end 26 located below the power head 16 . As can be seen from Figure 7, the staple cartridge 12 has a housing 28, the housing as Figure 5 and 6 There is shown a generally V-shaped face 30 and two parallel side walls 32a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com