Plain bearings

A bearing and bearing axis technology, applied in sliding contact bearings, bearings, bearings in rotary motion, etc., can solve the problems of fast wear of plastic lining materials, excessive sagging of doors, etc., and achieve the effect of avoiding polishing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring now to the drawings, wherein like technical features are indicated by like reference numerals.

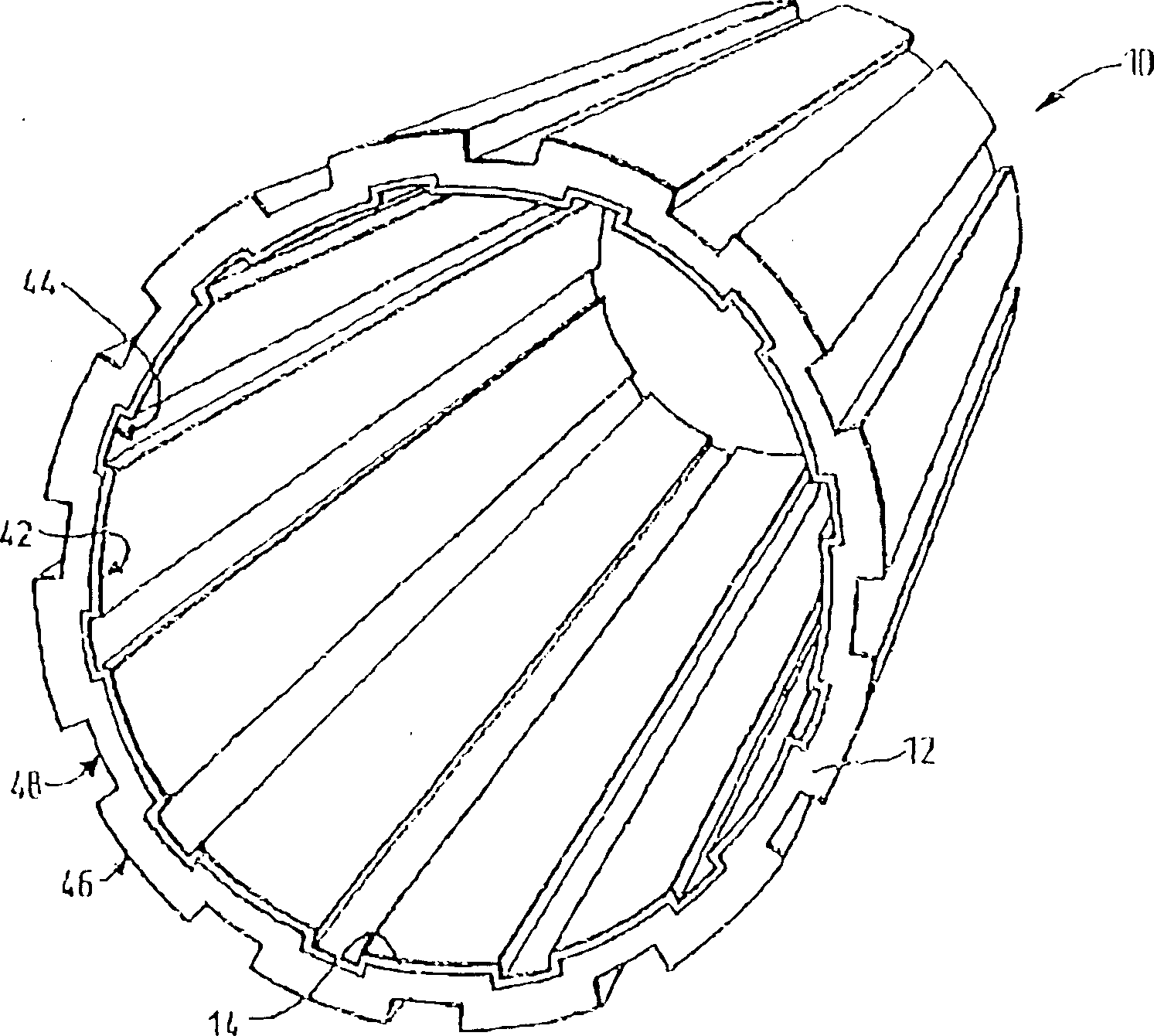

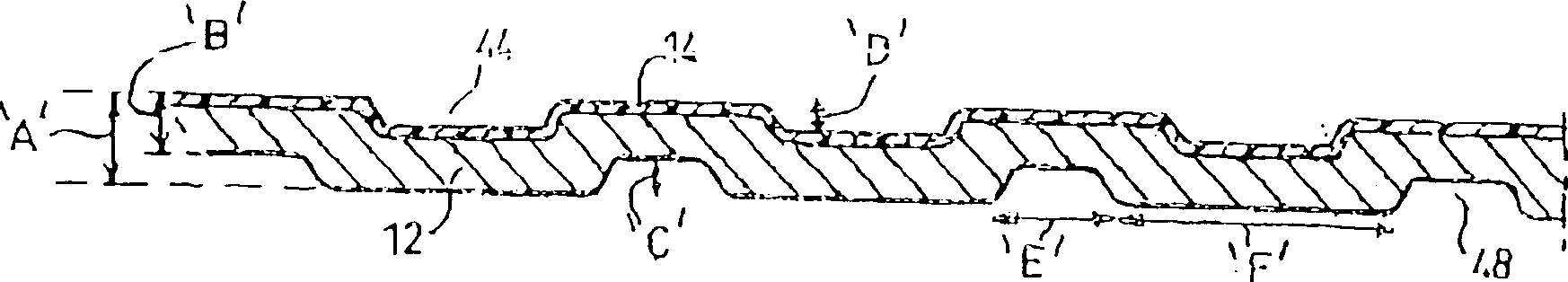

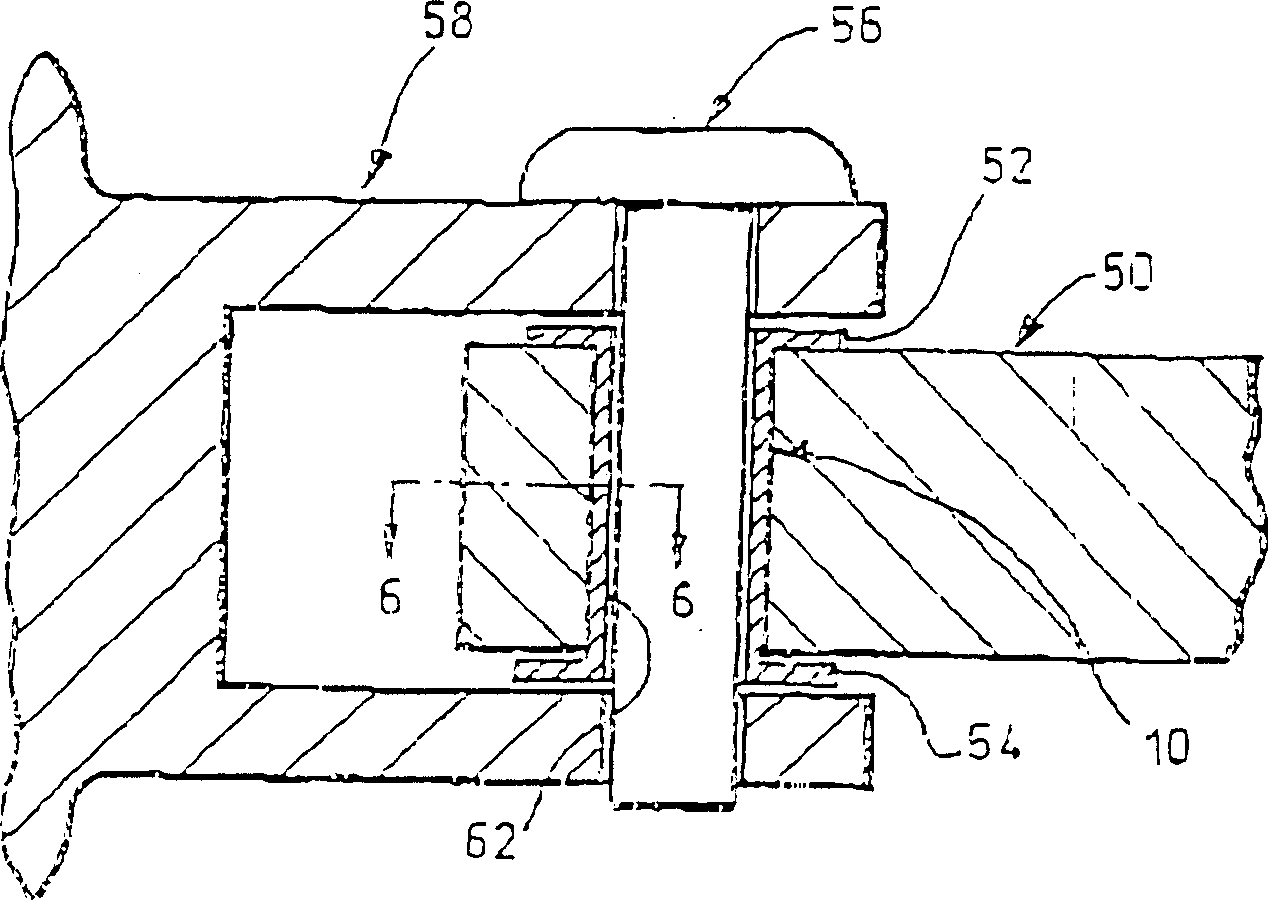

[0027] figure 1 A perspective view of the bearing bush 10 of the present invention is given. The liner is made from a flat strip of material (not shown) having a steel backing 12 and a plastic liner material 14 attached on one side thereof. In order to form corrugated material 40 (see Figure 5 with Image 6 ), it is necessary to make the flat strip material on the rollers 20,22 (see Figure 4 ) between. Rollers 20, 22 rotate about axes 24, 26, respectively, and have cooperating grooves 28, 30 and ridges 32, 34, wherein the ridges of one roller are receivable in grooves of the other roller. As the rollers approach each other, the incoming flat strip is deformed so that a corrugated structure 36 along the wall thickness of the flat strip is obtained. Thus, the corrugated strip 40 includes raised ridges 42 having the liner 14 thereon, each ridge 42 being separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com