Air bubble mixed light-weight earth

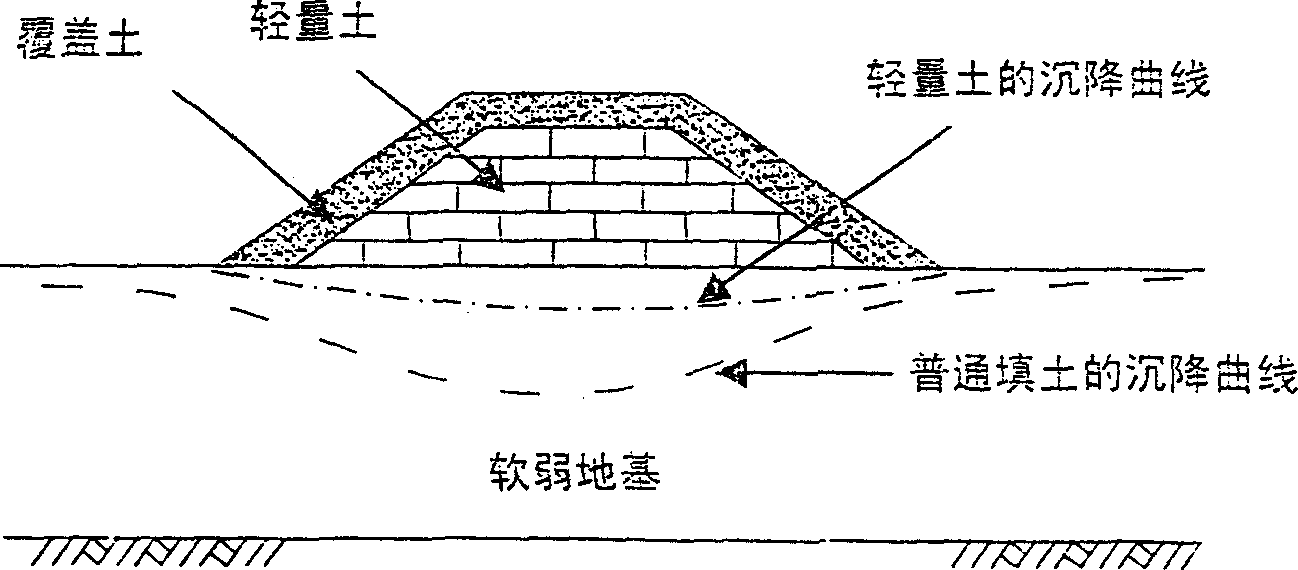

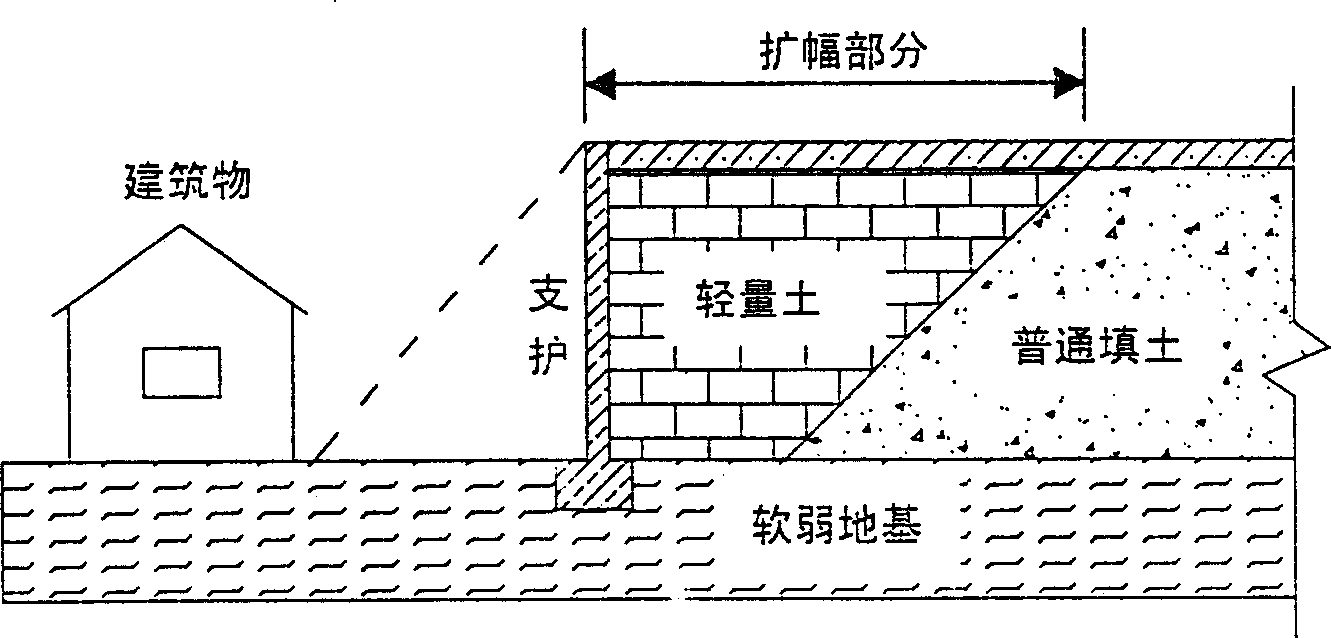

A lightweight soil and air bubble technology, applied in the fields of soil protection, climate sustainability, sustainable waste treatment, etc., can solve the lack of effective means and measures for the control and inspection of the construction weight of concealed projects, and the inconvenience of traffic and safe pipelines. Due to the safety of force and the difficulty of ordinary filling to meet the engineering requirements, the effect of ensuring anti-sliding stability, shortening the engineering period and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

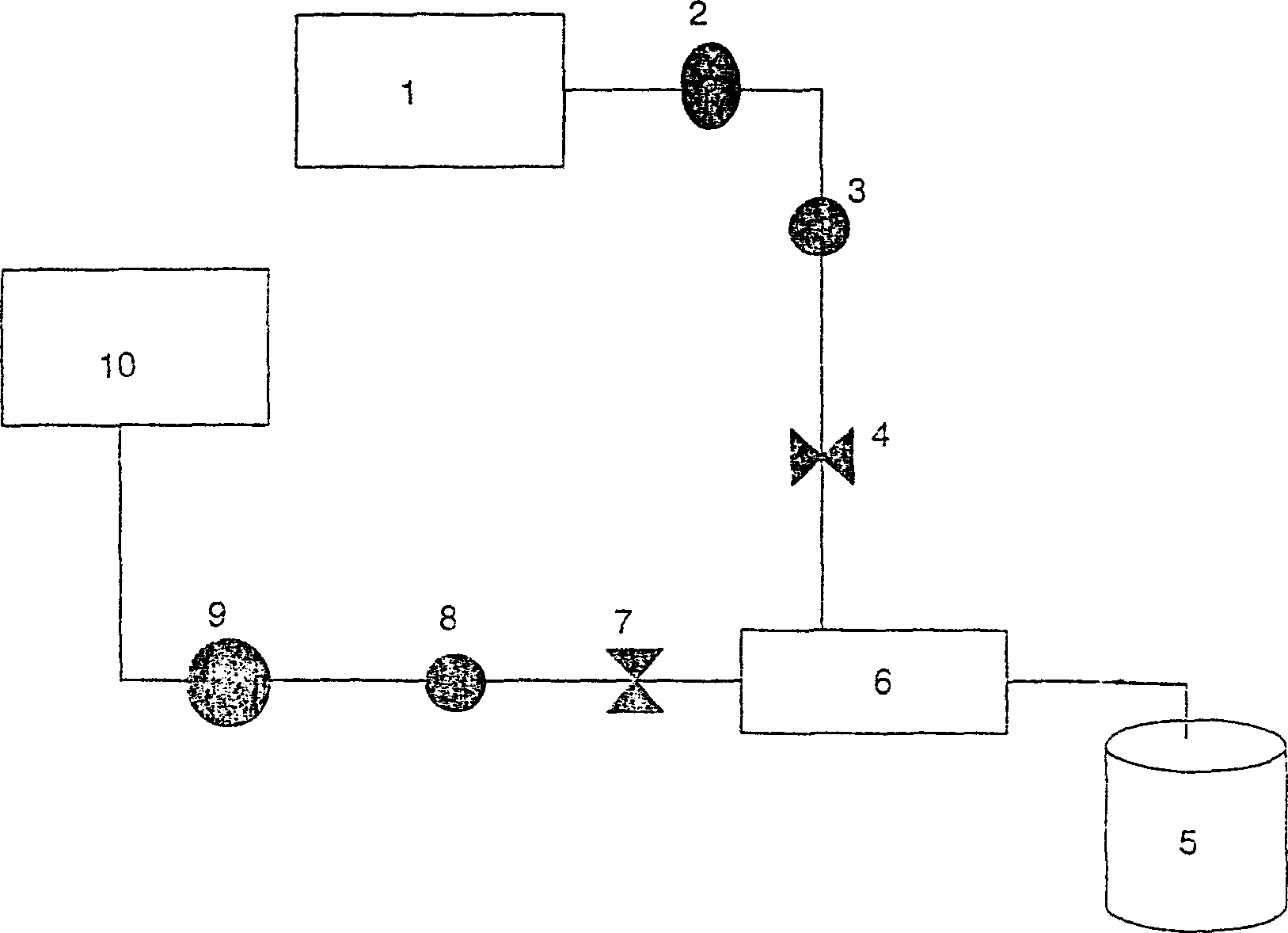

[0028] Clay, water, air bubbles, and cement are put into the mixing processor and mixed evenly together to make air bubble mixed lightweight soil. Take 100 kg of mixed material, the weight ratio of each component

[0029] Clay 78%

[0030] 32.5 # Cement 12%

[0031] Bubbles 1%

[0032] water 9%

[0033] Put the above clay, water and cement into the mixing processor and mix and stir to make the raw material soil slurry. Bubbles are obtained by foaming the foaming solution through a foaming device. Put the air bubbles into the mixing processor to mix and stir with the raw material soil slurry to make air bubble mixed lightweight soil slurry. Use a pump to press the air-bubble mixed lightweight soil slurry to the construction work surface for pouring construction to form lightweight fill.

[0034] Cured under the standard conditions of standard atmospheric pressure, temperature 18-20°C and humidity 100%, the wet density of 28 days is 1.02g / cm 3 , Unconfined compressive st...

Embodiment 2

[0036] Silt, water, air bubbles, and cement are put into the mixing processor and mixed evenly together to make air bubble mixed lightweight soil. Take 100 kg of mixed material, the weight ratio of each component

[0037] Silt 84%

[0038] 32.5 # Cement 15%

[0039] Bubbles 1%

[0040] Put the above silt and cement into the mixing processor and mix and stir to make the raw material soil slurry. Bubbles are obtained by foaming the foaming solution through a foaming device. Put the air bubbles into the mixing processor to mix and stir with the raw material soil slurry to make air bubble mixed lightweight soil slurry. Use a pump to press the air-bubble mixed lightweight soil slurry to the construction work surface for pouring construction to form lightweight fill.

[0041] Cured under the standard conditions of standard atmospheric pressure, temperature 18-20°C and humidity 100%, the wet density of 28 days is 1.0g / cm 3 , Unconfined compressive strength 258kPa. It is suita...

Embodiment 3

[0043]Sand, water, air bubbles, and cement are put into the mixing processor and mixed evenly together to make air bubble mixed lightweight soil. Take 100 kg of mixed material, the weight ratio of each component

[0044] Sand 70%

[0045] 32.5 # Cement 20%

[0046] Bubbles 1%

[0047] water 9%

[0048] The above-mentioned sand, water and cement are put into a mixing processor for mixing and stirring to make raw material soil slurry. Bubbles are obtained by foaming the foaming solution through a foaming device. Put the air bubbles into the mixing processor to mix and stir with the raw material soil slurry to make air bubble mixed lightweight soil slurry. Use a pump to press the air-bubble mixed lightweight soil slurry to the construction work surface for pouring construction to form lightweight fill.

[0049] Cured under the standard conditions of standard atmospheric pressure, temperature 18-20°C and humidity 100%, the wet density of 28 days is 0.76g / cm 3 , Unconfined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com