Disperse dye

A technology of disperse dyes and dye monomers, applied in the direction of organic dyes, etc., can solve the problems of overflow dyeing that is prone to match difference or even color flower, poor dyeing head and tail, poor compatibility, etc., to achieve good level dyeing and lifting , Excellent fastness performance and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

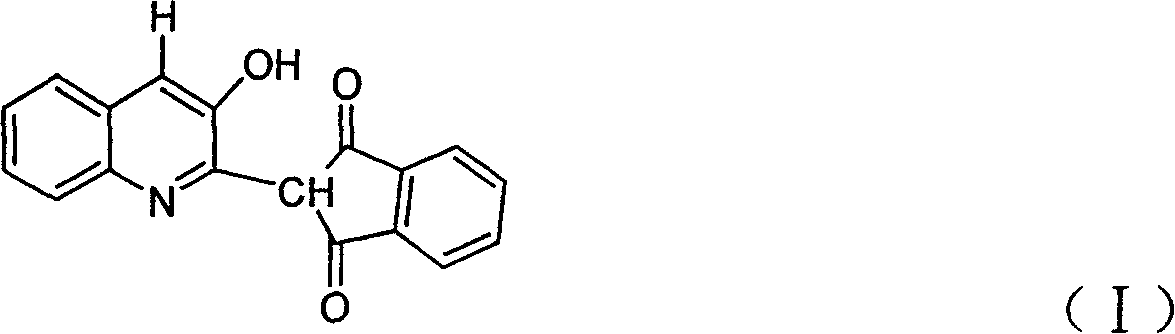

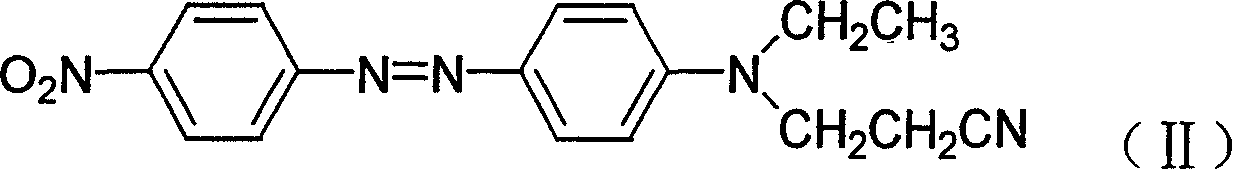

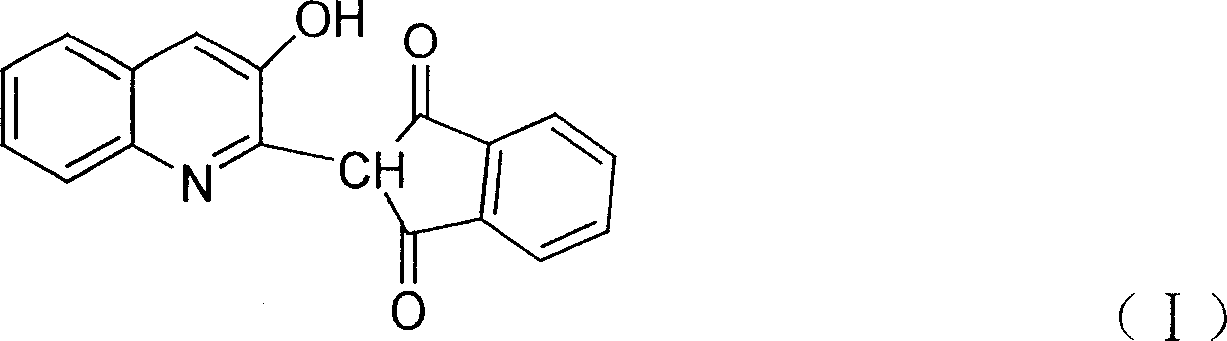

Image

Examples

Embodiment 1~7

[0021] According to the data shown in Table 1, dye monomer A, dye monomer B, auxiliary agent (dispersant methyl naphthalene sulfonate formaldehyde condensate (MF), diffusing agent benzyl naphthalene sulfonate formaldehyde condensate (CNF), Diffusion agent naphthalenesulfonic acid formaldehyde condensate (NNO), sodium ligninsulfonate) is blended with water, ground and dispersed with a grinder, and then spray-dried.

[0022] Example

Embodiment 8~10

[0024] According to the data shown in Table 2, C.I. Disperse Yellow 54 (commercial dye, monomer A content about 55%), C.I. Disperse Orange 25 (commercial dye, monomer B content about 42%), auxiliary agent (dispersant methylnaphthalene Sulfonic acid formaldehyde condensate (MF), diffusing agent benzyl naphthalene sulfonate formaldehyde condensate (CNF), diffusing agent naphthalenesulfonic acid formaldehyde condensate (NNO)) are blended with water, grind and disperse with a grinder, and then spray dry;

[0025] Example

Embodiment 11~14

[0027] According to the data shown in Table 3, C.I. Disperse Yellow 54 (commercial dye, monomer A content about 55%), C.I. Disperse Orange 25 (commercial dye, monomer B content about 42%), auxiliary agent (dispersant methyl naphthalene sulfonate Acid formaldehyde condensate (MF), diffusing agent naphthalenesulfonic acid formaldehyde condensate (NNO), sodium lignosulfonate) are blended directly, and ground until uniformly dispersed.

[0028] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com