Gas turbine

A gas turbine, hot gas technology, applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of cooling air loss pressure, no solution provided, unable to return to the combustion chamber, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

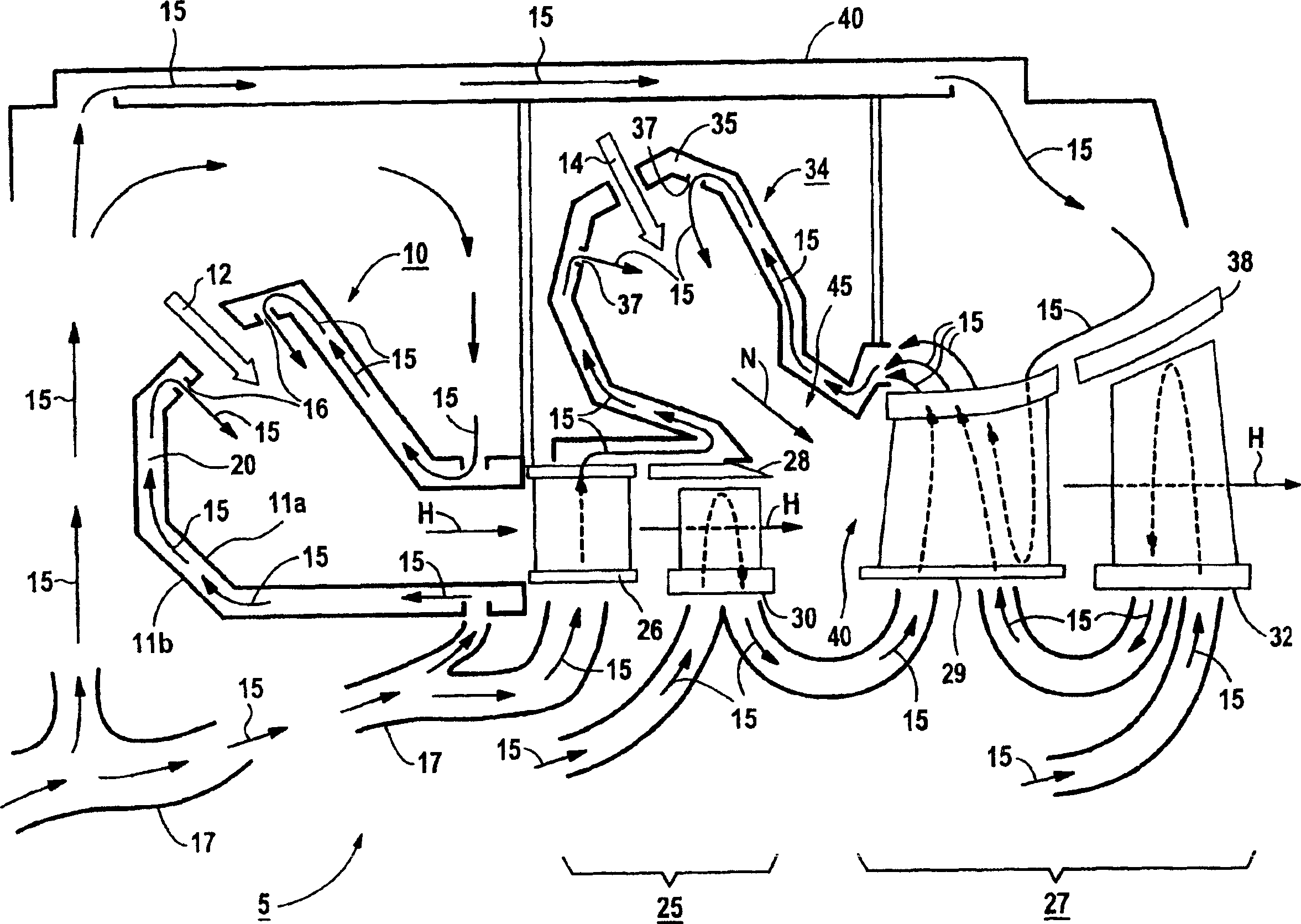

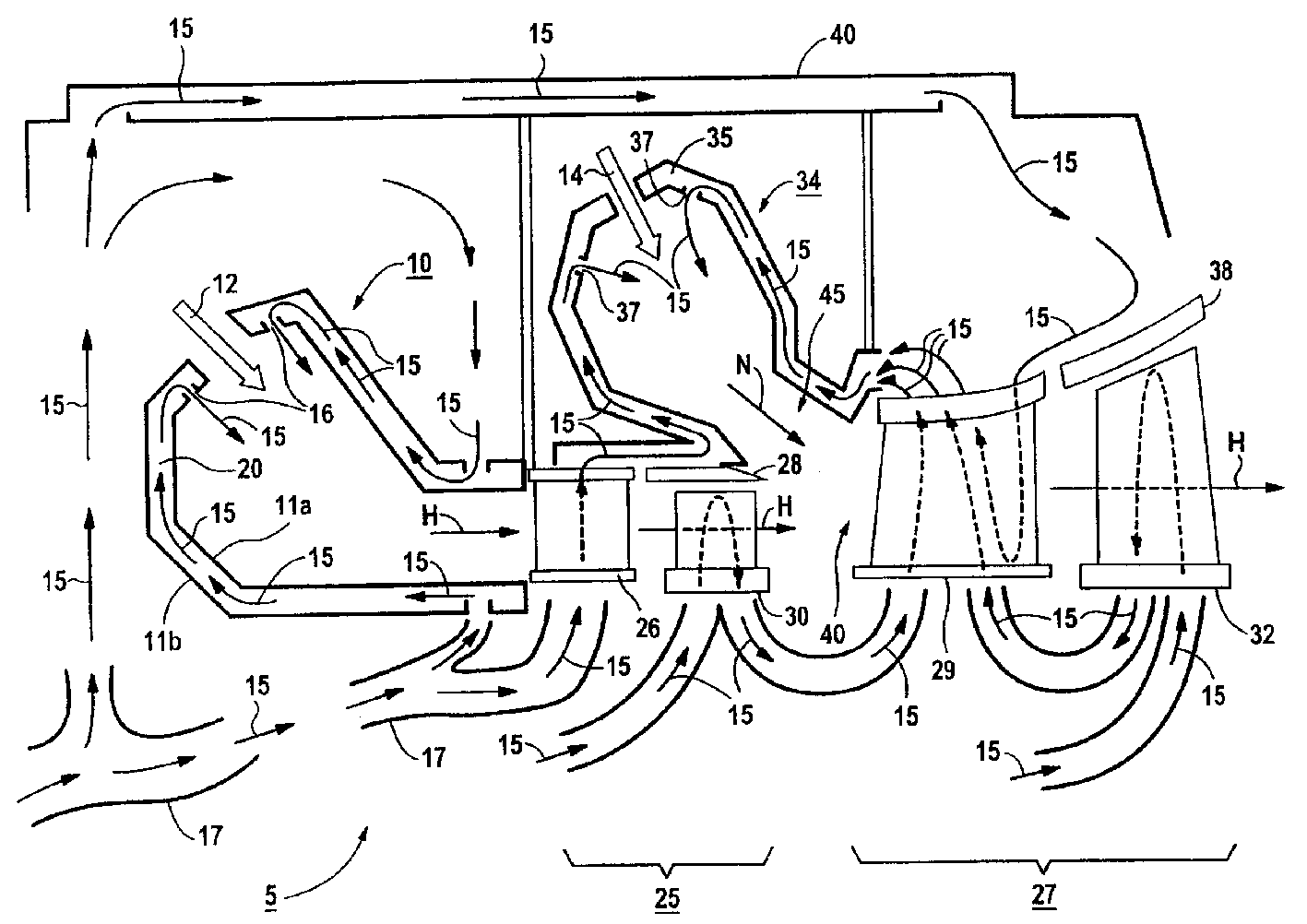

[0031] The gas turbine 5 comprises a main combustion chamber 10 , the combustion chamber of which is closed off by a combustion chamber wall 11 a. The main combustion chamber 10 is separated from the outside by a combustion outer wall 11b, so that a cooling air channel 20 is formed between the combustion chamber wall 11a and the combustion outer wall 11b.

[0032] During the working process of the gas turbine 5, the compressor gas mixture 12 produced by the compressor is sent into the main combustion chamber 10, where it is burned by an unillustrated burner located in the main combustion chamber 10 to form a hot gas mixture. The hot gas mixture then drives rotor blades 30 and 32 of turbine stages 25 and 27 in sequence.

[0033] The cooling air 15 is sent into the cooling air passage 20 of the main combustion chamber 10 to cool the side of the combustion inner wall 11 a facing away from the main combustion chamber 10 . The cooling air 15 enters the inner cavity of the main com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com