Flatbed knitting machine

A knitting machine and horizontal technology, applied in weft knitting, flat knitting machines with individual moving needles, knitting, etc., can solve the problem of changing work requiring a lot of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

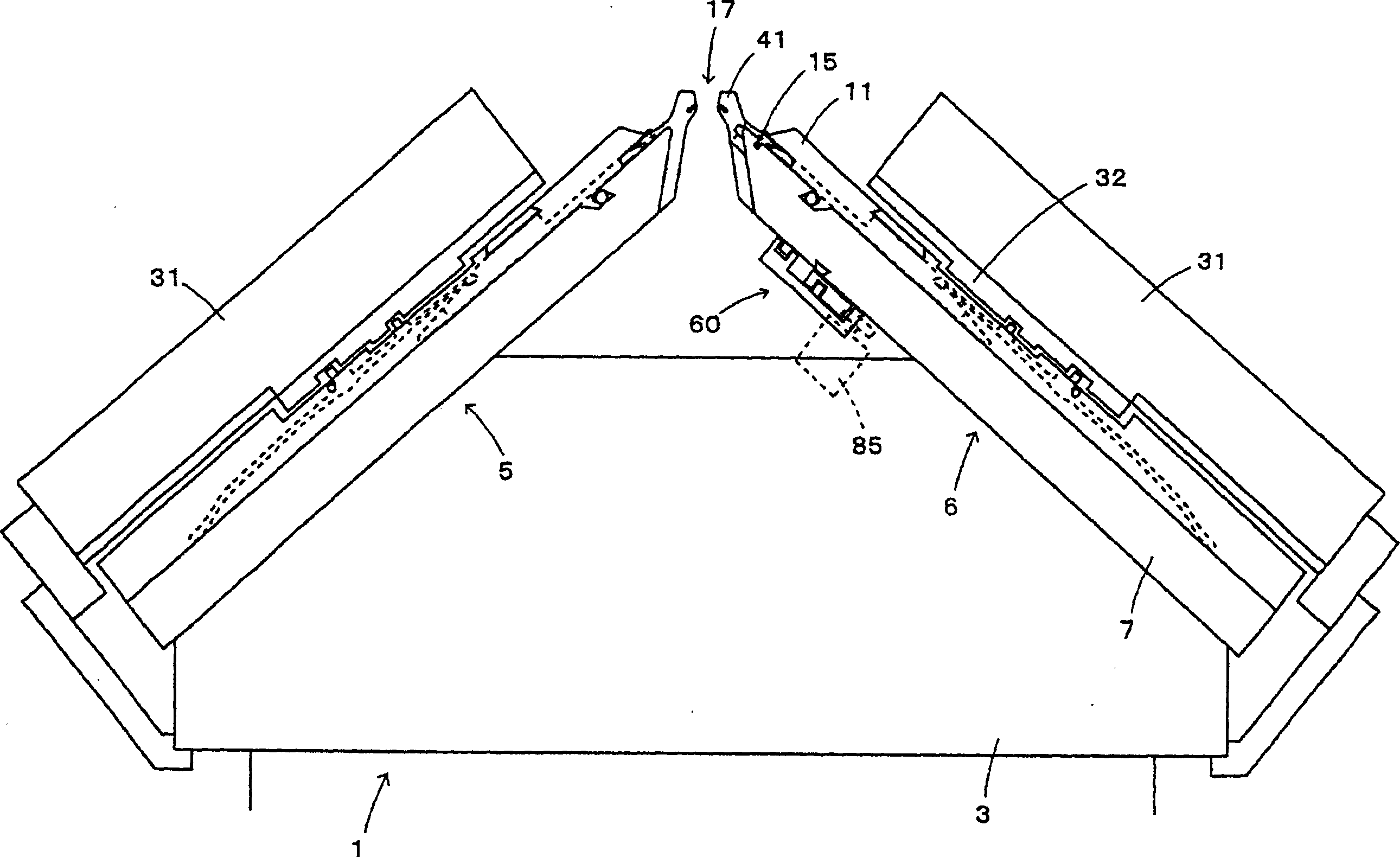

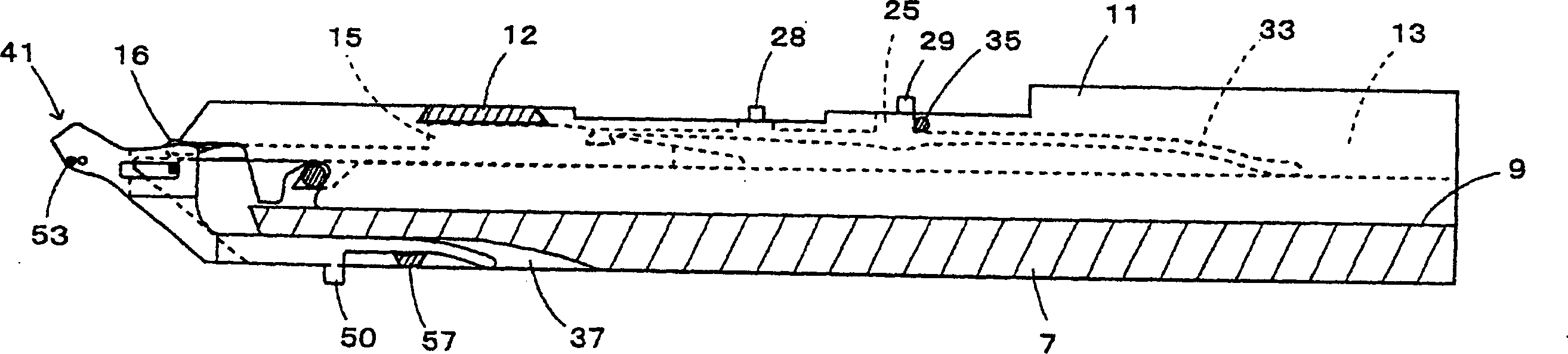

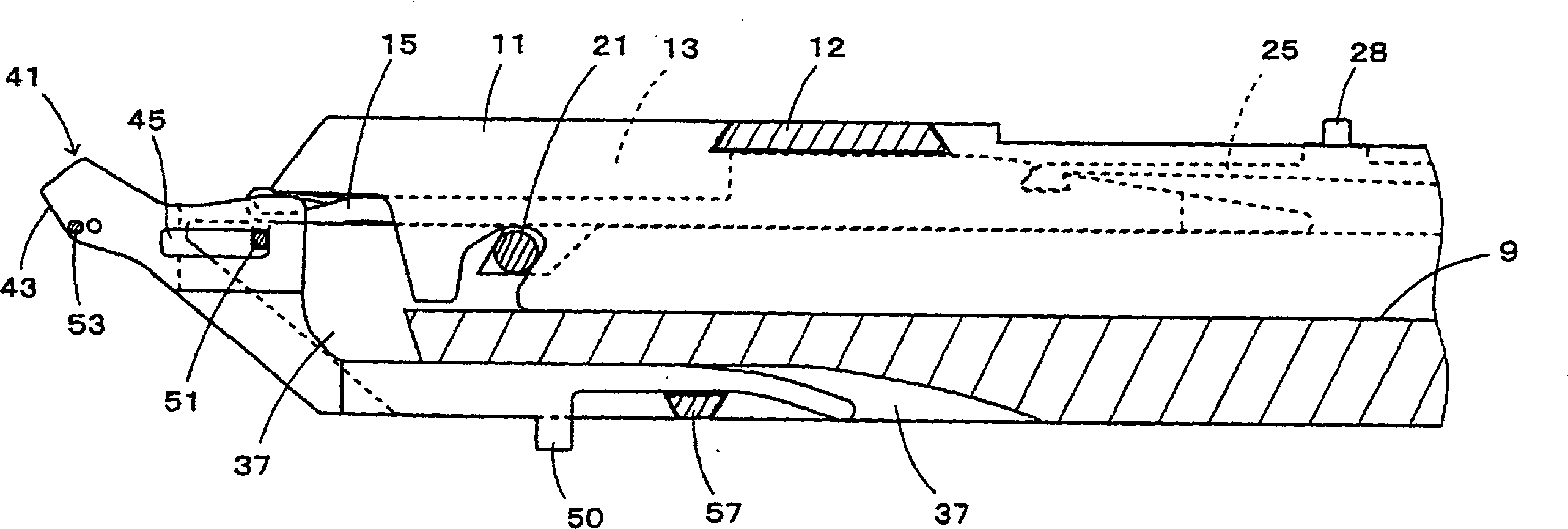

[0036] In the transverse knitting machine 1 of this embodiment, the front and rear needle beds formed by arranging a plurality of needles and sinkers in parallel are oppositely arranged in an inverted V shape. figure 1 It is a side view schematically showing the needle bed portion of the horizontal knitting machine. figure 2 is a cross-sectional view showing the rear needle bed (the operating device described later is omitted), image 3 yes figure 2 Enlarged view of the frontmost portion of the needle bed shown. Fig. 4 is a diagram showing main parts constituting the needle bed. In this specification, the movement of the tooth gap between the front and rear needle beds is expressed as entering, and the opposite movement is expressed as backward. In addition, when describing each part of the horizontal knitting machine, the part facing the crest is shown as the front, and the opposite part is shown as the back.

[0037]The front needle bed 5 and the rear needle bed 6 are ...

Embodiment 2

[0054] The needle bed of the horizontal knitting machine in the above-mentioned embodiment has a structure in which the sinkers, through which the piano wires forming the tip of the needle bed are inserted, are supported at the front end of the needle bed freely. Needle bed 101 in, from Figure 9 It can be seen from the shown sectional view that the needle bed base plate 103 is formed separately from the body portion 105 and the front end portion 107 . 10a and 10b show a state in which the main body portion 105 and the front end portion 107 constituting the needle bed base plate 103 are separated.

[0055] On the front end portion of the substrate body portion 105 of the needle bed 101, a support portion 111 is formed, and the support portion 111 is embedded in a recessed portion 113 formed on the rear end surface of the substrate front end portion 107 to support the substrate front end portion 107 on the substrate body. Section 105 on. Grooves 117 and 118 for inserting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com