Fixture for preparing coating on selected area of blade surface and coating preparation method

A blade and coating technology, which is applied in the field of jig and coating preparation, can solve problems such as the reduction of blade fatigue strength, the impact of engine performance, and the shedding of the area near the blade tip, etc., to reduce erosion damage, simple and convenient use, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

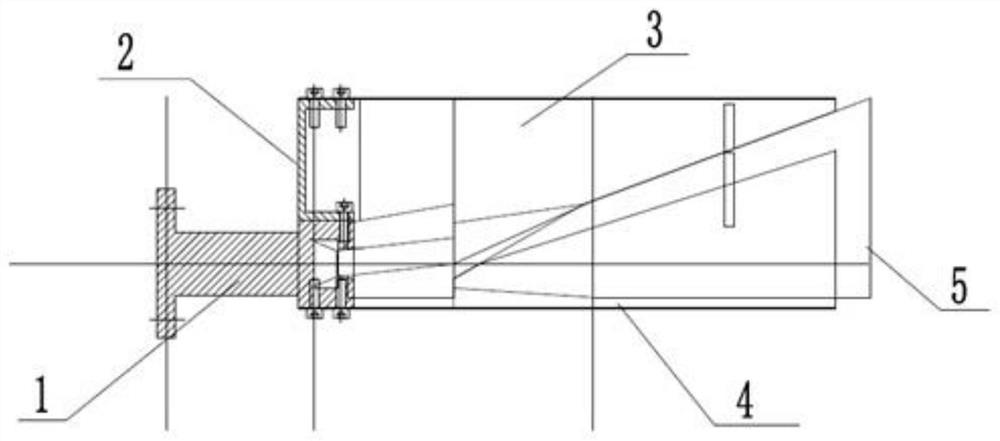

[0054] When in use, according to the service requirements of the blade, it is necessary to control the size of the ion release gap by adjusting the size of the clamping gap. When preparing a gradient layer coating that meets the erosion and fatigue performance requirements on the blade surface, use It is necessary to adjust the width of the clamping gap to 2mm, and spray a coating with a gradient layer as an example, we can follow the steps below to assemble the fixture:

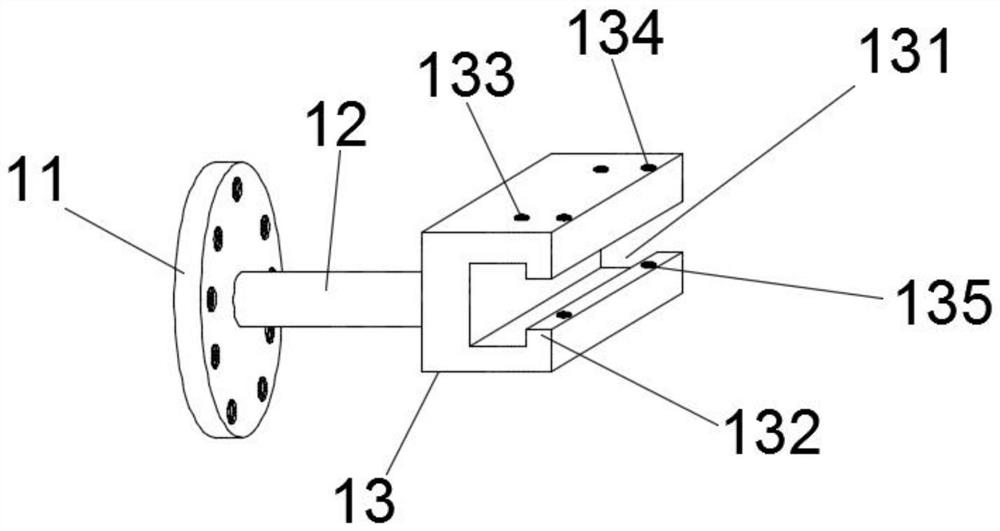

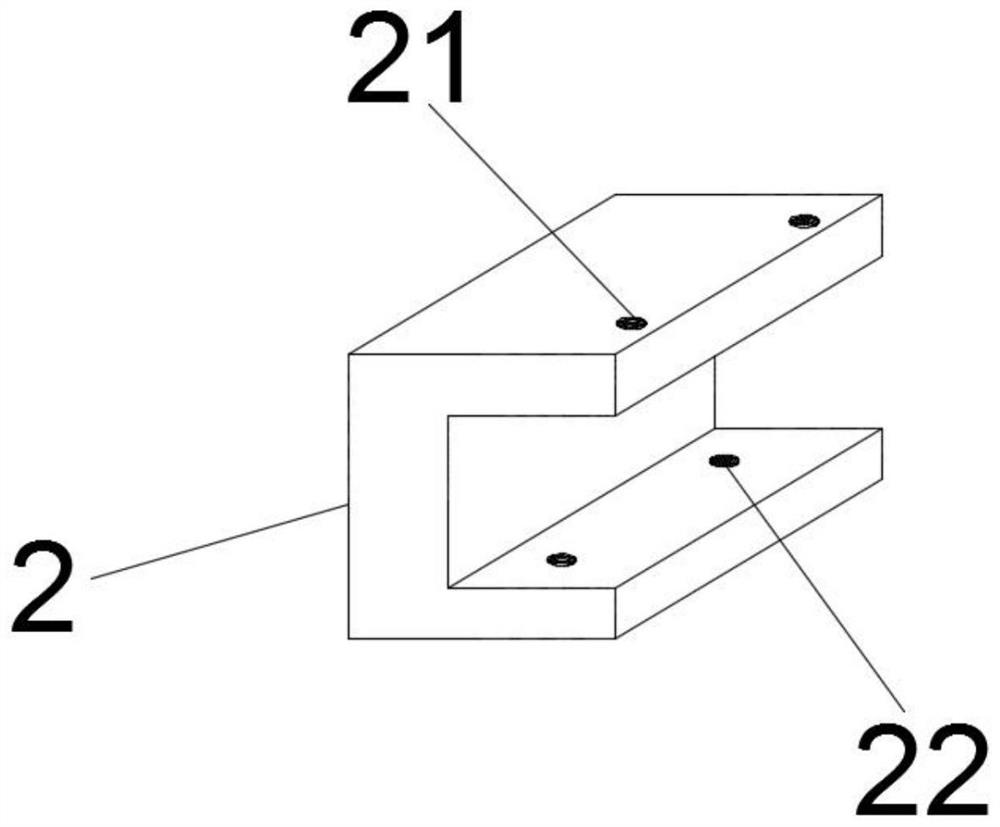

[0055] Step 1: First, use the hexagonal bolts to sequentially pass through the fifth threaded connection hole 22 and the first threaded connection hole 133 to connect the blade fixed shaft 1 to the cover plate bracket 2; then connect the blade fixed shaft 1 to the cover plate bracket 2, and connect the The tenon part of the blade (engine or turbine) that needs to be prepared with a gradient coating is clamped in the tenon part clamping groove 131. After the blade is fixed, install the lower cover plate 4 and ...

Embodiment 2

[0065] The difference from Example 1 is that in use, according to the service requirements of the blade, it is necessary to control the size of the ion release gap by adjusting the size of the clamping gap, and prepare a non-gradient blade on the surface of the blade that meets the requirements of erosion and fatigue performance. When coating the coating, we need to adjust the width of the clamping gap to 0.2mm and spray the coating without gradient layer as an example. We can assemble the fixture according to the following steps:

[0066]Step 1: First, use the hexagonal bolts to sequentially pass through the fifth threaded connection hole 22 and the first threaded connection hole 133 to connect the blade fixed shaft 1 to the cover plate bracket 2; then connect the blade fixed shaft 1 to the cover plate bracket 2, and connect the The tenon part of the blade (engine or turbine) that needs to be prepared with a gradient coating is clamped in the tenon part clamping groove 131. Af...

Embodiment 3

[0075] Different from Embodiment 2 and Embodiment 1, according to the different sizes of the blades, it is necessary to adjust the relative position of the fixed shaft 1 and the cover plate bracket 2 on the upper cover plate 3 and the lower cover plate 4 to adjust the volume of the blade installation cavity Size, so that the parts of blades of different volumes that need to be sprayed can extend out of the clamping gap, so as to meet the needs of spraying on the surface of the blades. When preparing a gradient coating that meets the requirements of erosion and fatigue performance, this embodiment adopts This is achieved in the following ways:

[0076] We are also provided with a first sliding fixing groove 312 on the upper top plate 31. The first sliding fixing groove 312 is used in conjunction with the fourth threaded connection hole 21 and the hexagon bolt. When in use, pass the hexagon bolt through the first sliding fixing groove in turn 312 and the fourth threaded connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com