Surface shear plasticization method and device

An inclined surface and grinding disc technology, which is applied in the field of polymer material forming and processing, can solve the problems of increased axial pressure on the grinding disc surface, large gap resistance of the grinding disc, and long residence time, etc., and achieves the effect of improving the mixing degree and solving the large gap resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

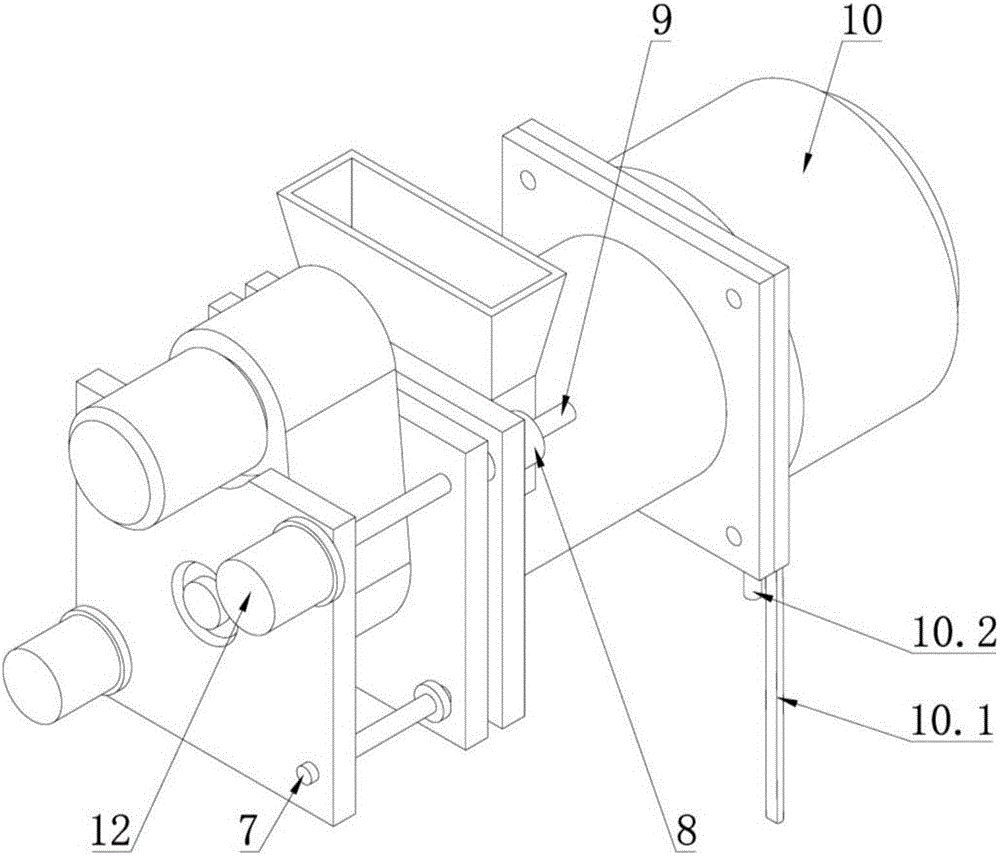

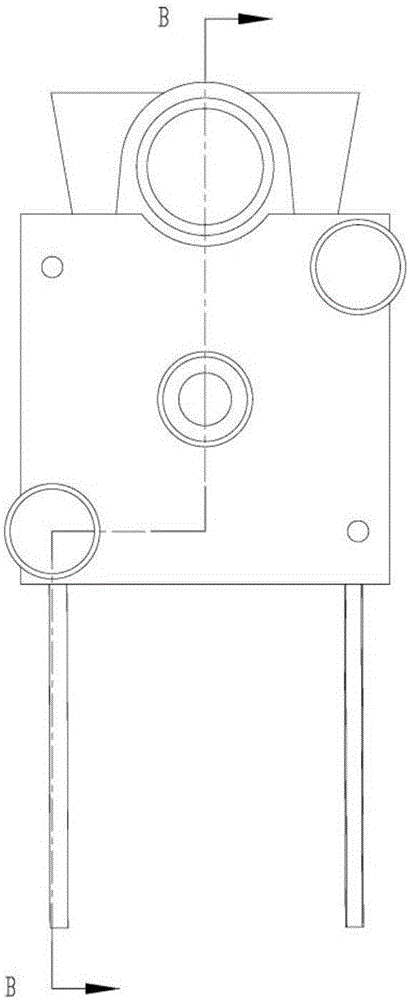

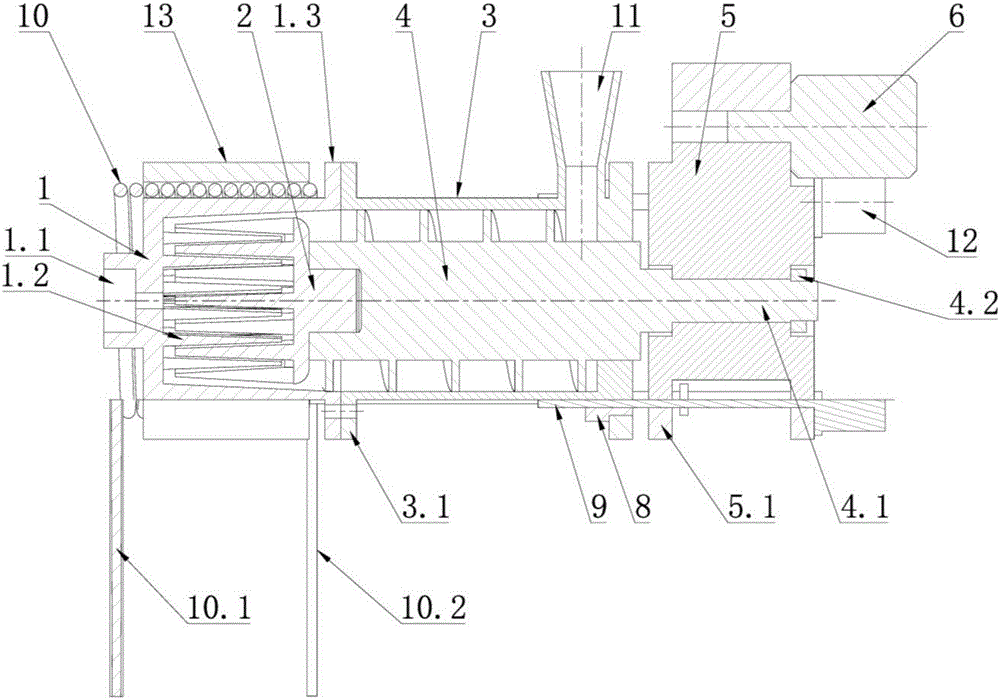

[0058] Inner sleeve 2 has a diameter of 210mm, four layers of cylindrical grinding discs, a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 170mm. Outer sleeve 1 has a diameter of 260mm, including four layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 170mm.

[0059] The disc gap is 1mm. There are 6 material passages (notches) between layers, and the passage width is 20mm.

[0060] The outer diameter of the screw is 230mm, the length is 420, the pitch is 20mm, and the groove depth is 6mm. Speed 150rpm.

Embodiment 2

[0062] Inner sleeve 2 has a diameter of 150 mm, three layers of cylindrical grinding discs, layer thickness of 10 mm, inclination of 3°, and grinding disc length of 120 mm. Outer sleeve 1 has a diameter of 200mm, including three layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 3°, and a grinding disc length of 120mm.

[0063] The disc gap is 1.5mm. The number of interlayer material passages (gap) is 4, and the passage width is 15mm.

[0064] The outer diameter of the screw is 170mm, the length is 320, the pitch is 20mm, and the depth of the screw groove is 6mm. Speed 150rpm.

Embodiment 3

[0066] Inner sleeve 2 has a diameter of 90mm, two layers of cylindrical grinding discs, a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 100mm. Outer sleeve 1 has a diameter of 140mm, including three layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 100mm.

[0067] The disc gap is 1.5mm. The number of interlayer material channels (gap) is 3, and the channel width is 10mm.

[0068] The outer diameter of the screw is 110mm, the length is 320, the pitch is 20mm, and the depth of the screw groove is 6mm. Speed 100rpm.

[0069] The invention adopts the butt joint method of the inner and outer sleeves with ring-shaped comb teeth to form surface shearing and grinding, and the material passes through the gap between the butted cylindrical grinding disc sleeves, and can also pass through the tooth gaps of the ring-shaped comb teeth in turn. The sleeve grinding di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com