Integrated exhaust gas recirculation system for internal combustion engine

A technology of recirculation system and exhaust gas recirculation valve, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve the problems of high cost and excessive engine downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

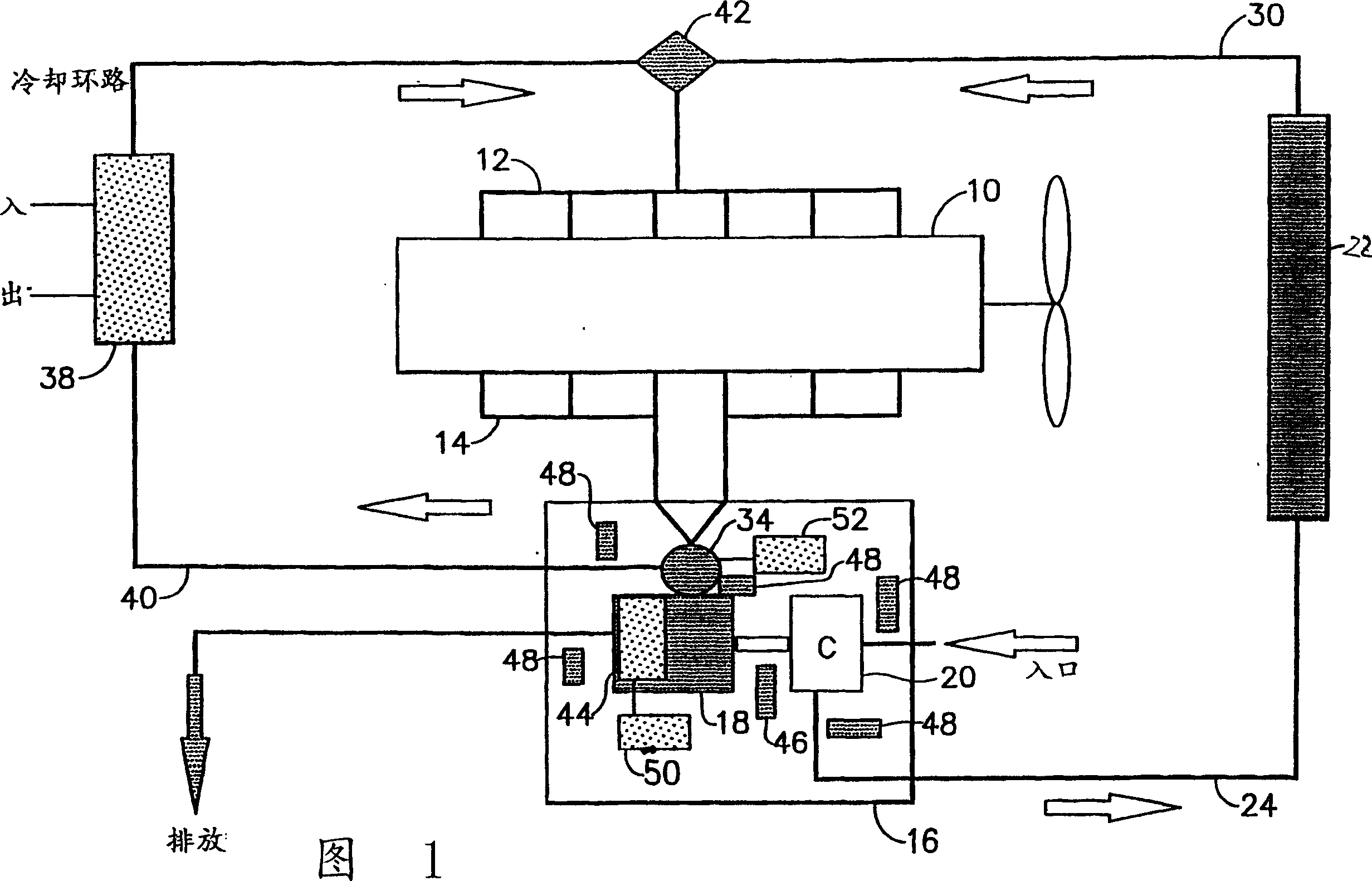

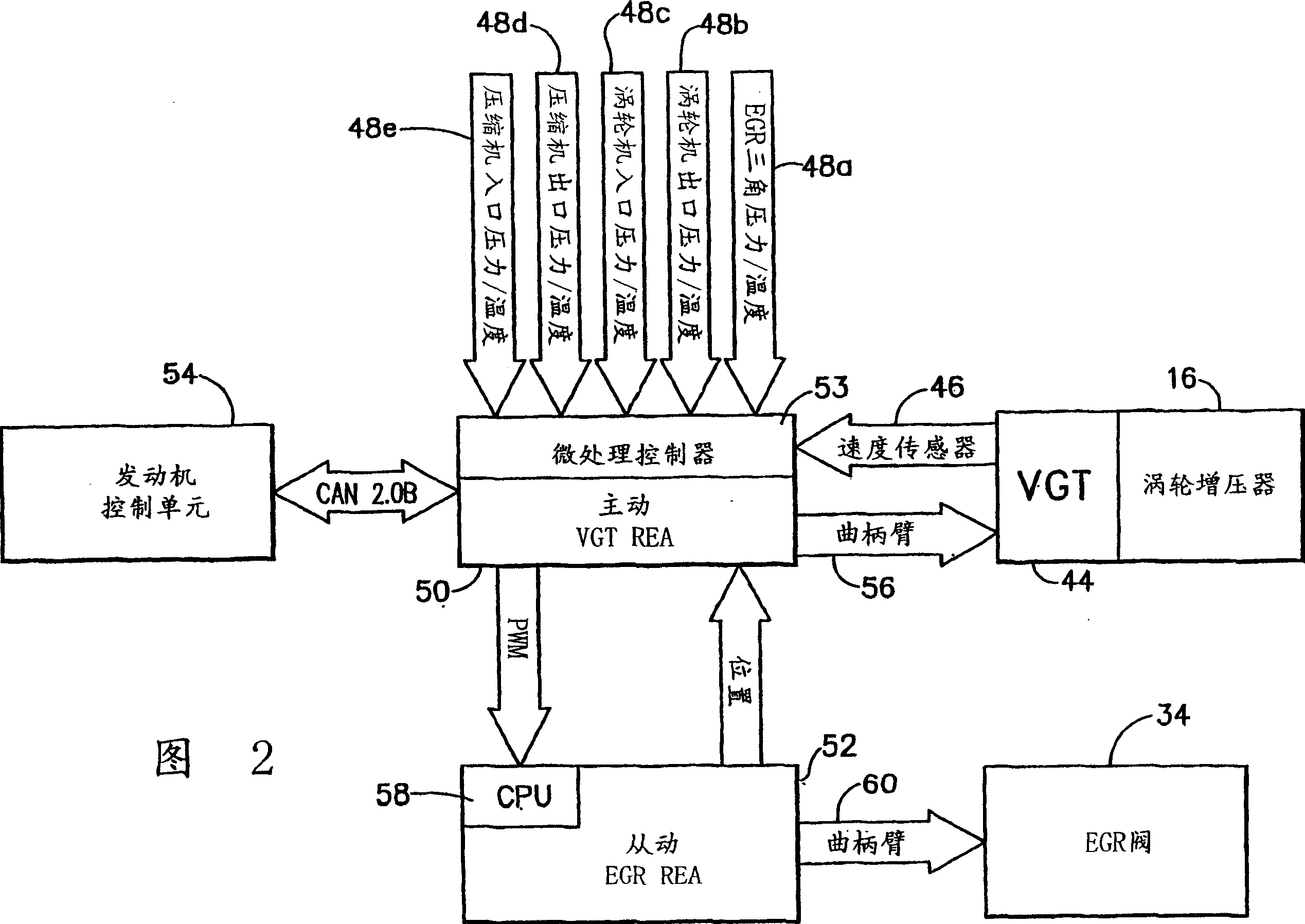

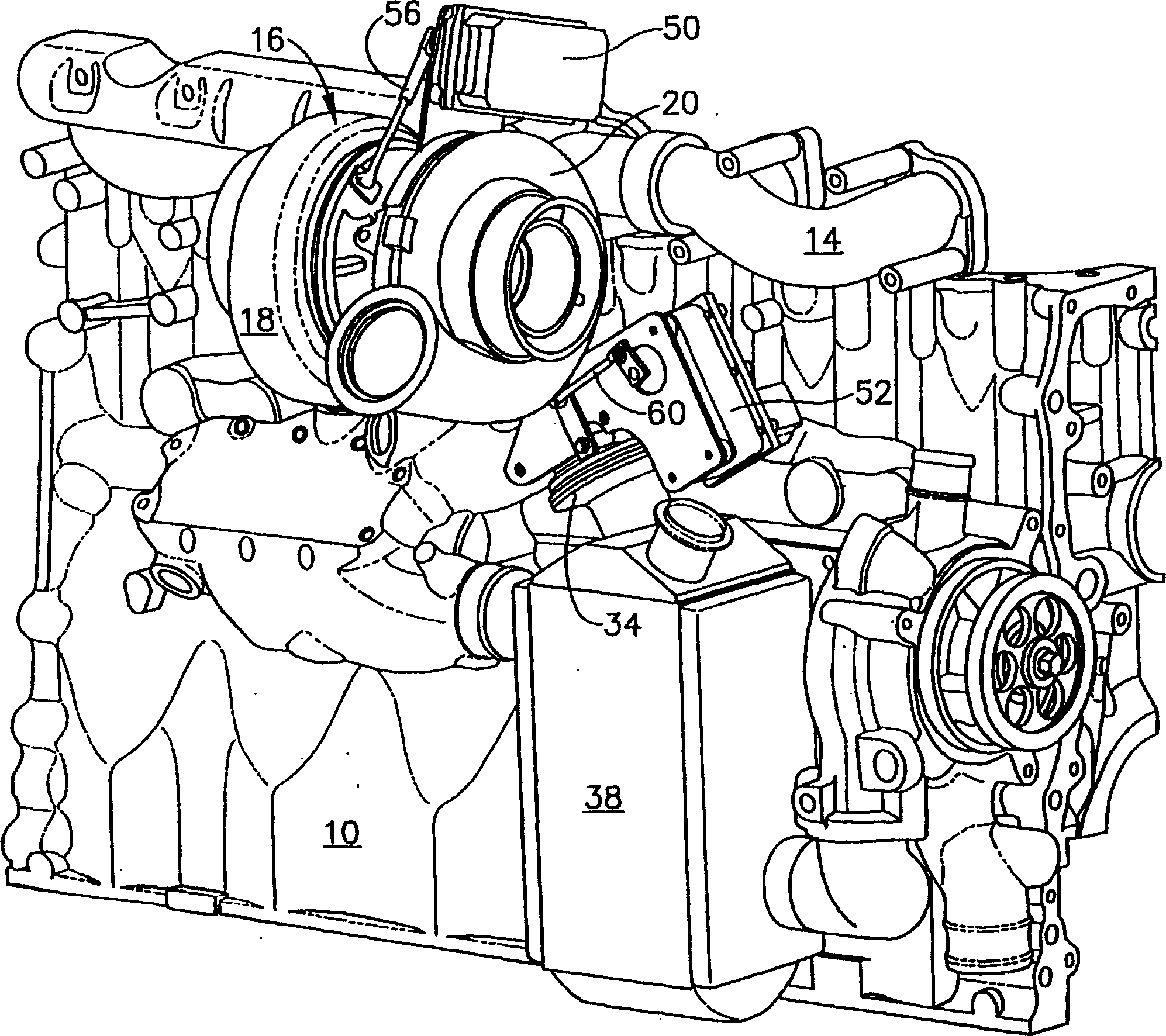

[0023] Referring to FIG. 1 , an internal combustion engine with a turbocharger and an EGR system is shown diagrammatically. Engine 10 includes an intake manifold 12 and an exhaust manifold 14 . In the illustrated embodiment, the engine includes a turbocharger 16 which generally includes a turbine housed in a housing 18 and a compressor housed in a housing 20 for compressing input air to the engine 10 . This input air is heated during turbocharger compression, however it must be cooled in order to meet engine durability and operating requirements. Cooling is accomplished in the passage of gases expelled from the turbocharger 16 to a charge air cooler (CAC) 22 via a common conduit or passage 24 . This input air is then routed from the charge air cooler to the intake manifold port of the engine through a common conduit or passage 30 .

[0024] The engine 10 also includes an EGR system. This EGR system comprises a control valve 34, and this control valve is integrated in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com