Fast connecting flange

A technology for connecting flanges and sealing rings. It is used in flange connections, pipes/pipe joints/fittings, and passing components. It can solve the problems of easy compression deformation, small tightening contact surface, leakage of the original flat retaining ring, etc. Simple application, good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

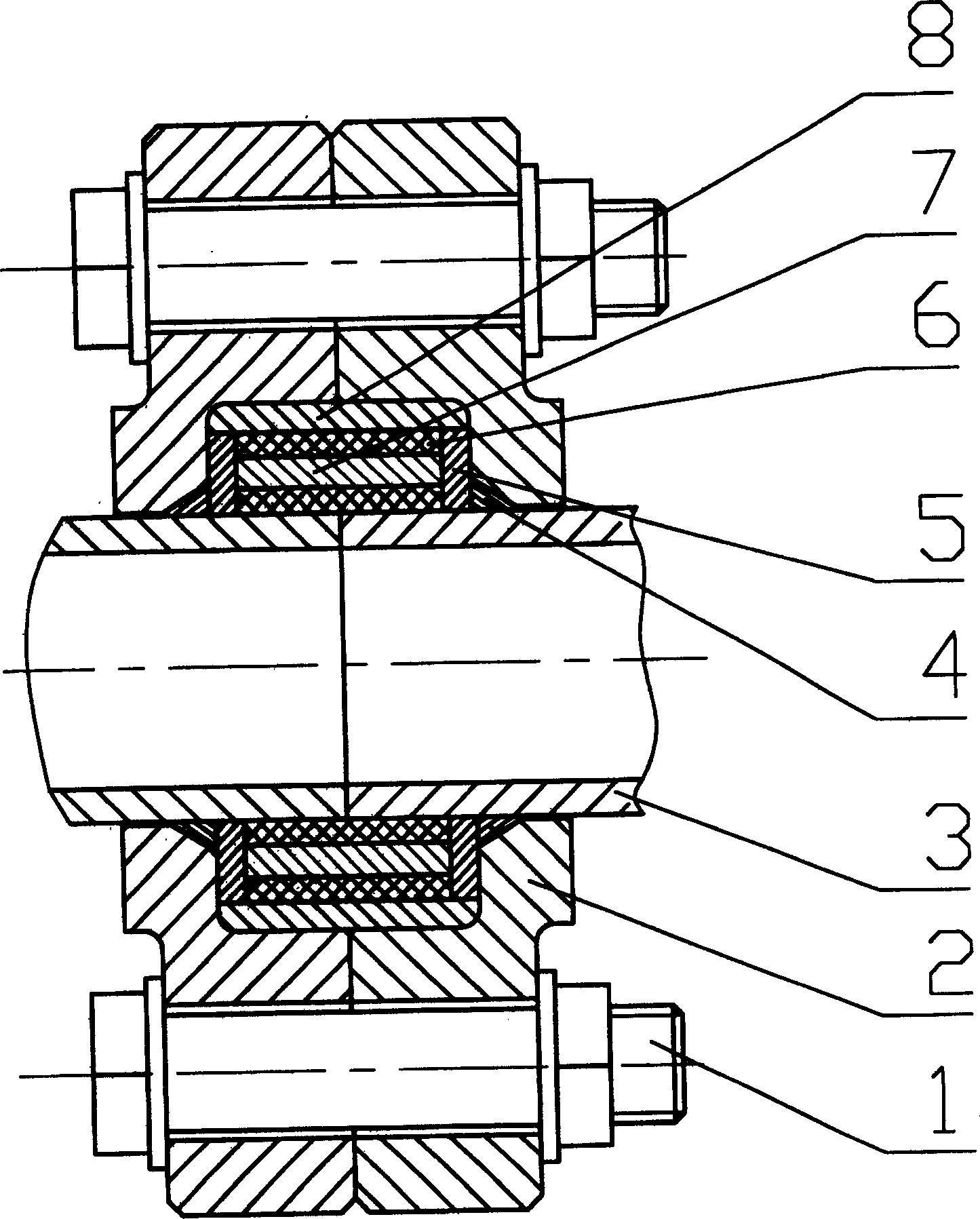

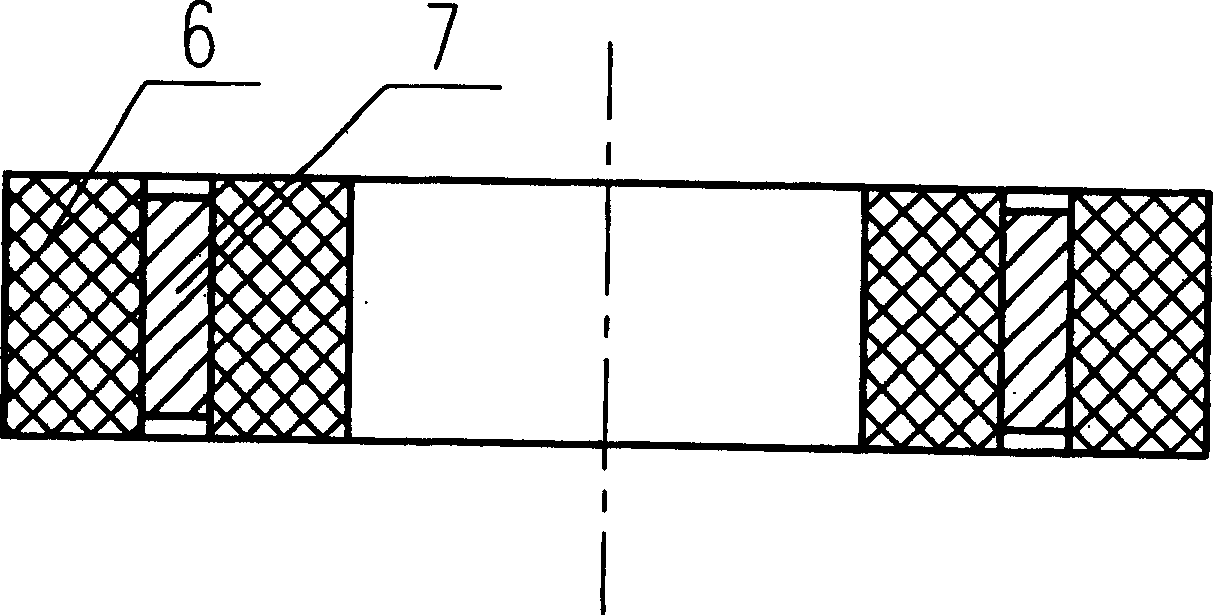

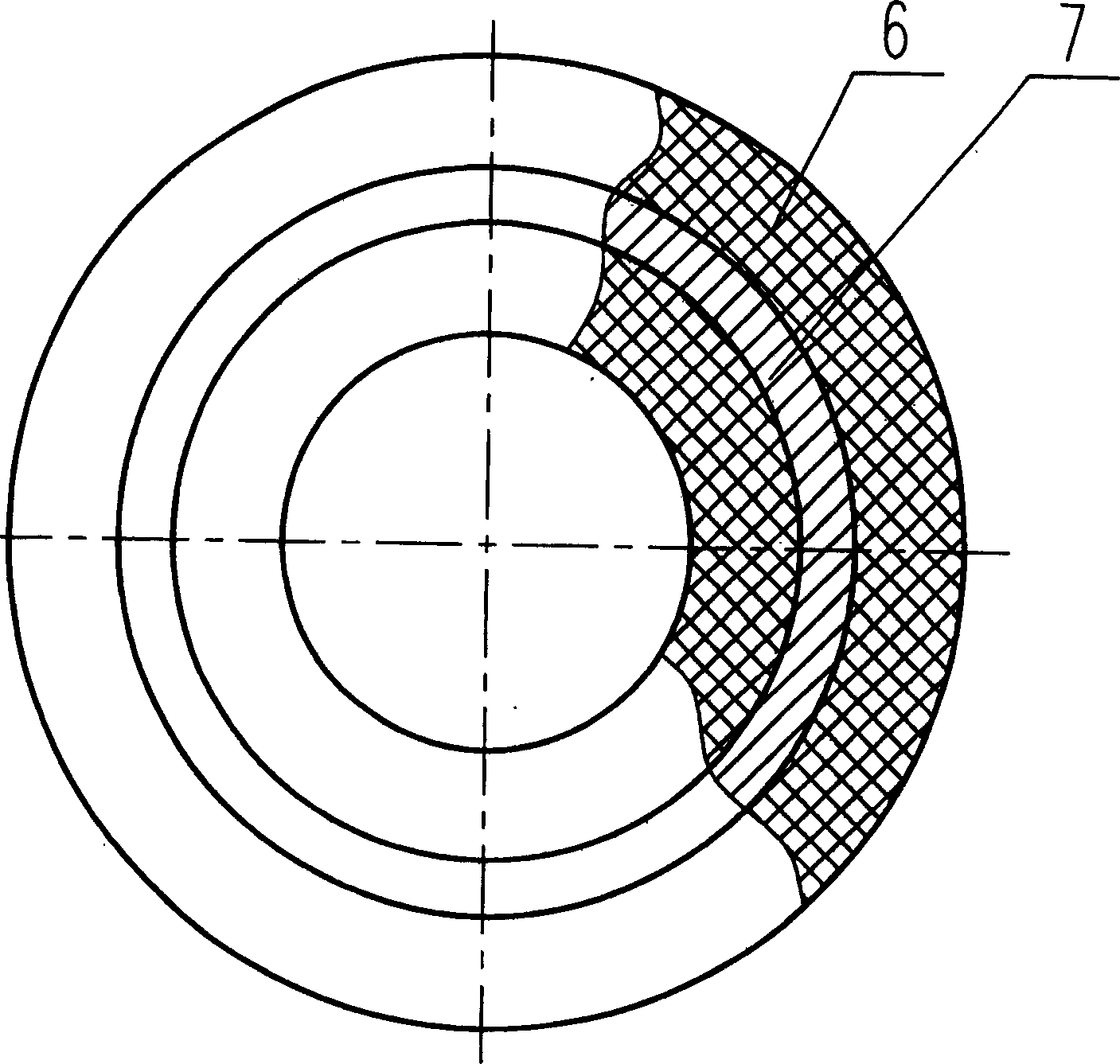

[0025] Such as figure 1 , 2 , 3, the present invention includes a wedge-shaped flange 2, the flange 2 is provided with fastening bolts 1, the flange 2 is provided with a sealing ring 6, and the sealing ring 6 is respectively provided with a flat washer 5, Cylindrical pressure retaining rings 8 are arranged outside the flat washers 5, and the flat washers 5 are respectively in contact with the locking wedge iron 4, and the flat washers 5 are in contact with the flange plate 2. When connecting to high-pressure flange pipes, the sealing A limiting cylinder 7 may be provided in the ring 6 .

[0026] When in use, the present invention is placed at the pipe material 3, and then tightened step by step with the fastening bolt 1, so that the applied force of the locking wedge iron 4, the flat washer 5, and the limit cylinder 7 reaches the set compression of the sealing ring 6 After standardization, the fastening bolt 1 is gradually tightened, so that the above-mentioned pressure is a...

Embodiment 2

[0028] Such as Figure 4 , 6 As shown, the flat washer 5 is provided with a pressure retaining ring 8 in the shape of a boss with a stop to ensure the connection between the present invention and various valves, and the others are the same as in Embodiment 1.

Embodiment 3

[0030] Such as Figure 7 As shown, a cylindrical pressure retaining ring 8 can be provided outside the flat washer 5, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com