Self-aligning socket connector

A socket connector, connector technology, applied in the direction of connection, parts of connecting devices, parts of electrical measuring instruments, etc., can solve the deformation of lead 106, incomplete contact between lead 106 and terminal 107, incomplete frictional contact, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As shown in the accompanying drawings, the present invention can allow different forms of embodiments, and a specific embodiment will be described in detail here. This disclosure is considered to be the embodiment of the gist of the present invention, but is not limited to the illustrated embodiments of the present invention. and describe the content.

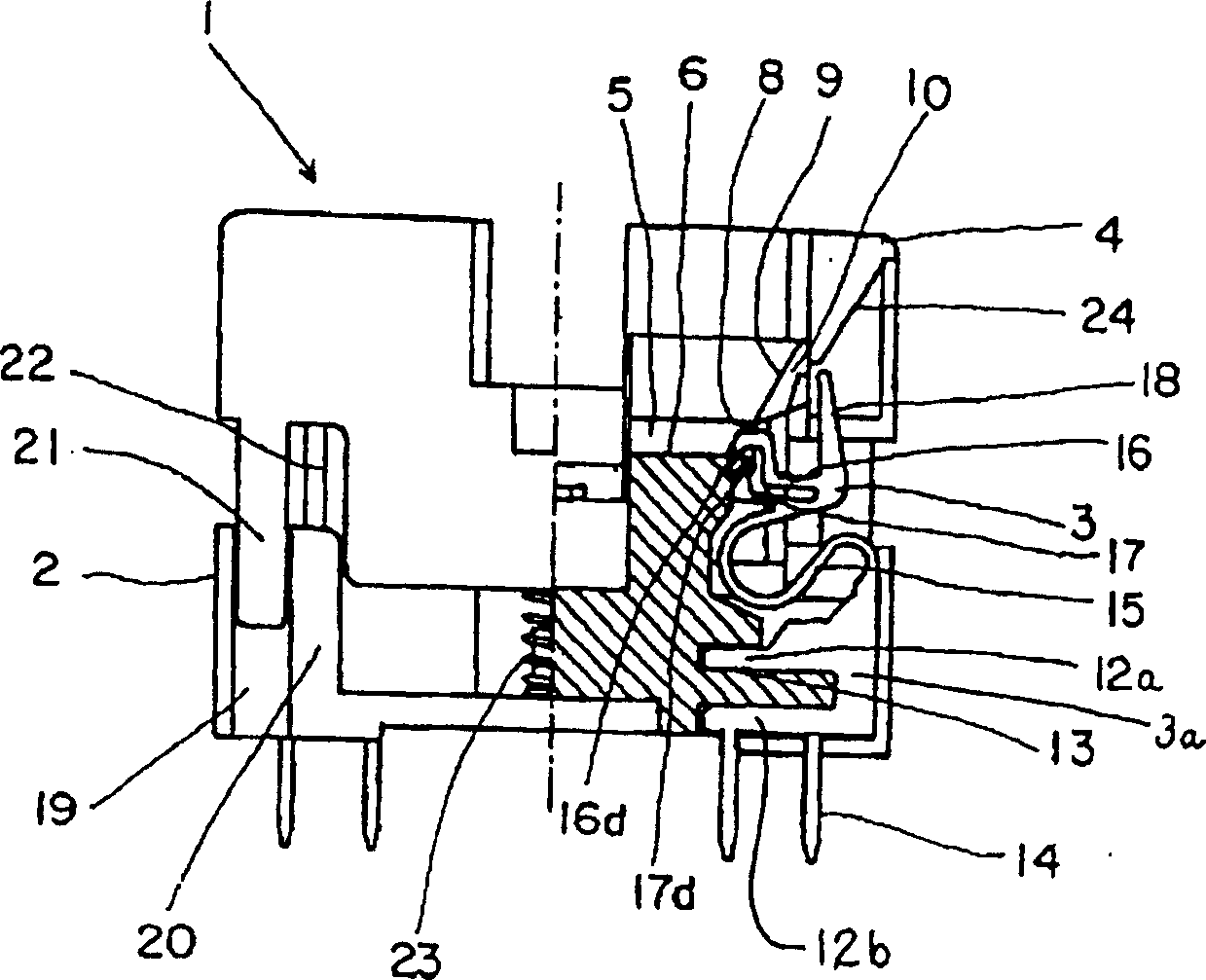

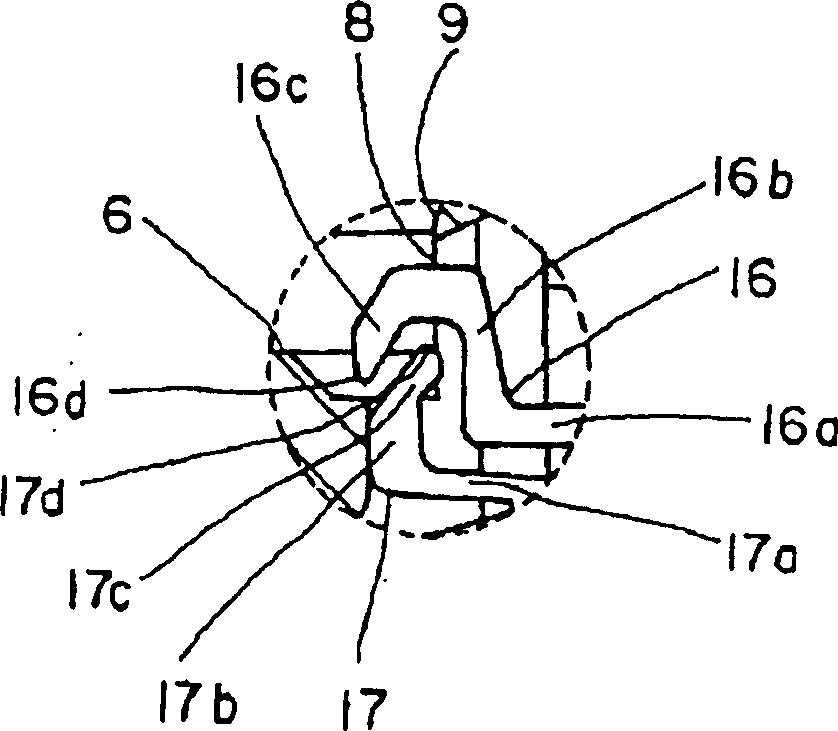

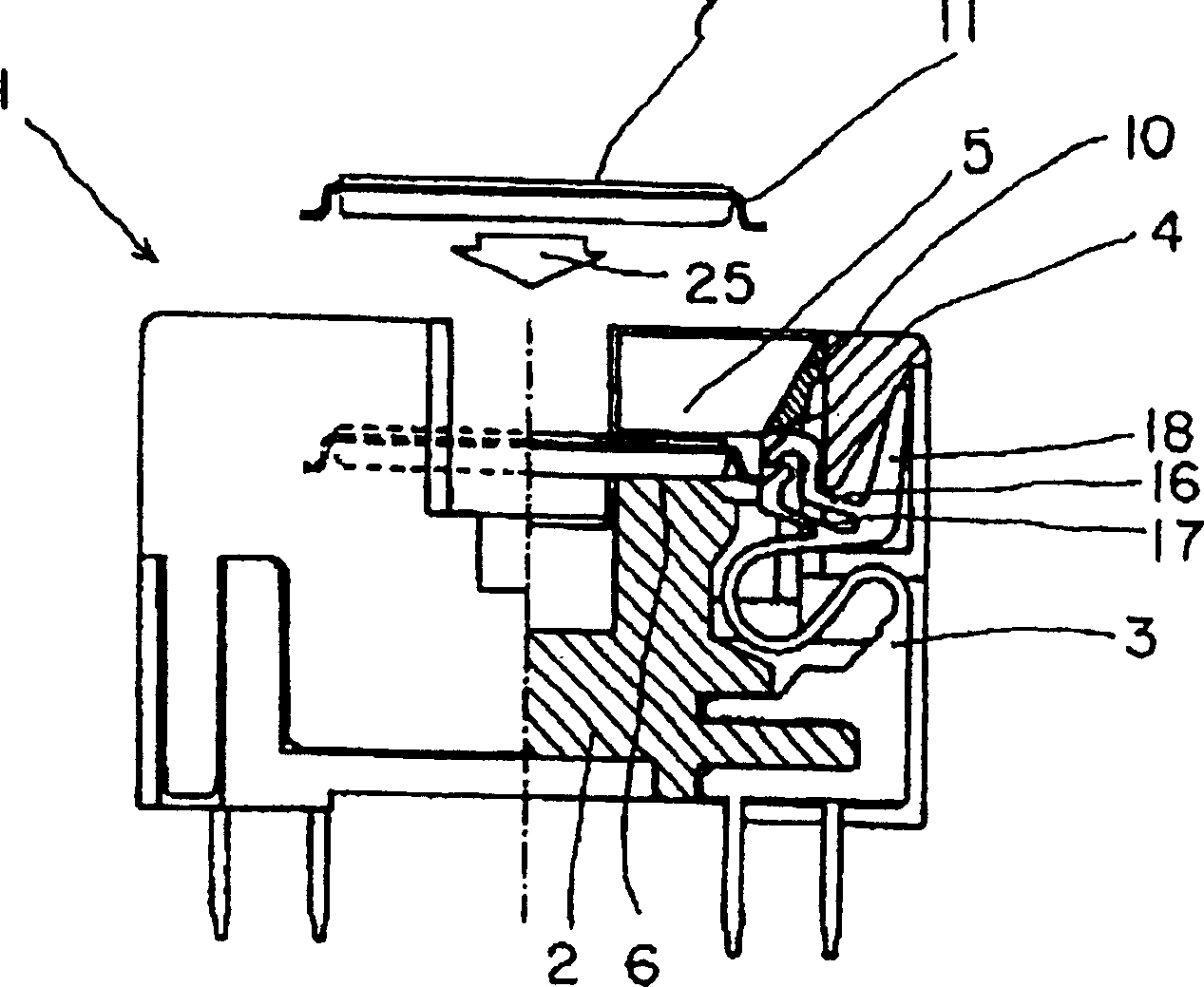

[0024] Please refer to figure 1 According to an embodiment of the present invention, an IC socket 1 includes a socket body 2 in which a plurality of terminals 3 are installed, and a cover-shaped actuator 4 is used to actuate the terminals 3 by the leads of the IC assembly. The socket body 2 has an encapsulation chamber 5 formed therein. The floor of the encapsulation chamber 5 provides a seating surface 6 for the IC package. IC assembly 7 (see image 3 ) is placed in the packaging chamber 5 so that it can be placed flat on the seat surface 6 , and its leads 11 are engaged with the terminals 3 of the socket 1 . It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com