Special vehicle for transporting winding green tire of engineering tire

A technology for engineering tires and special vehicles, applied in transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of large capital and manpower investment, waste of time, and cumbersome processes, and achieve the effect of improving efficiency, simplifying processes and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

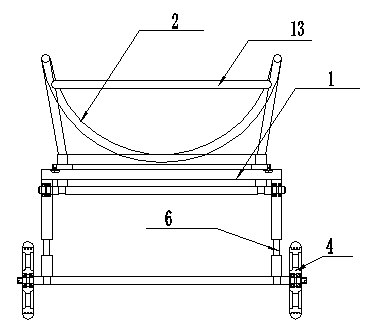

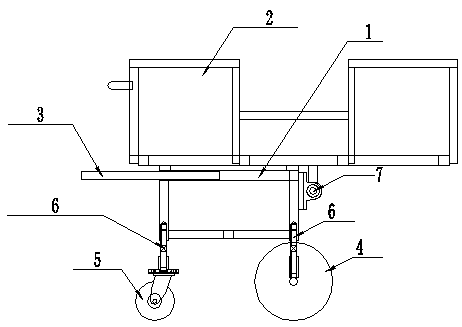

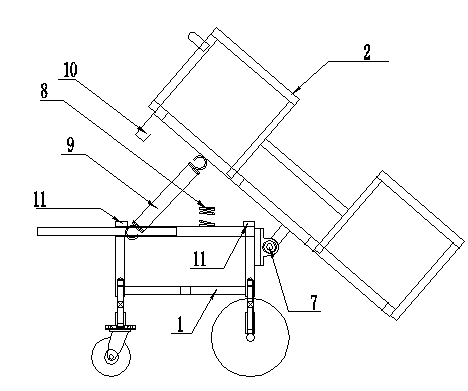

[0015] Such as figure 1 , 2 As shown in , 3, a special vehicle for transporting engineering tires by winding embryos, including a body 1 and a embryo storage device 2, the rear end of the body 1 is provided with a handle 3, and the steering wheels 5 and load-bearing wheels 4 pass through the height adjustment device 6 respectively. Installed under the car body 1, the load-bearing wheels 4 are in front and the direction wheels 5 are behind. The middle and front part of the green tire storage device 2 is hinged to the front end of the car body 1 through the rotating shaft 7, and the rear part of the green tire storage device 2 is reset. The spring 9 is connected to the upper surface of the vehicle body 1, the rear end of the tire storage device 2 is provided with a reset locking device 10, the front end of the tire storage device 2 is provided with a horizontal tire positioning rod 13, and the buffer spring 8 is installed on the vehicle body 1. In the middle of the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com