Binary-material composite oil cup

A composite oil cup and binary material technology, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of low hanging foot strength and easy softening and deformation of the cup body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

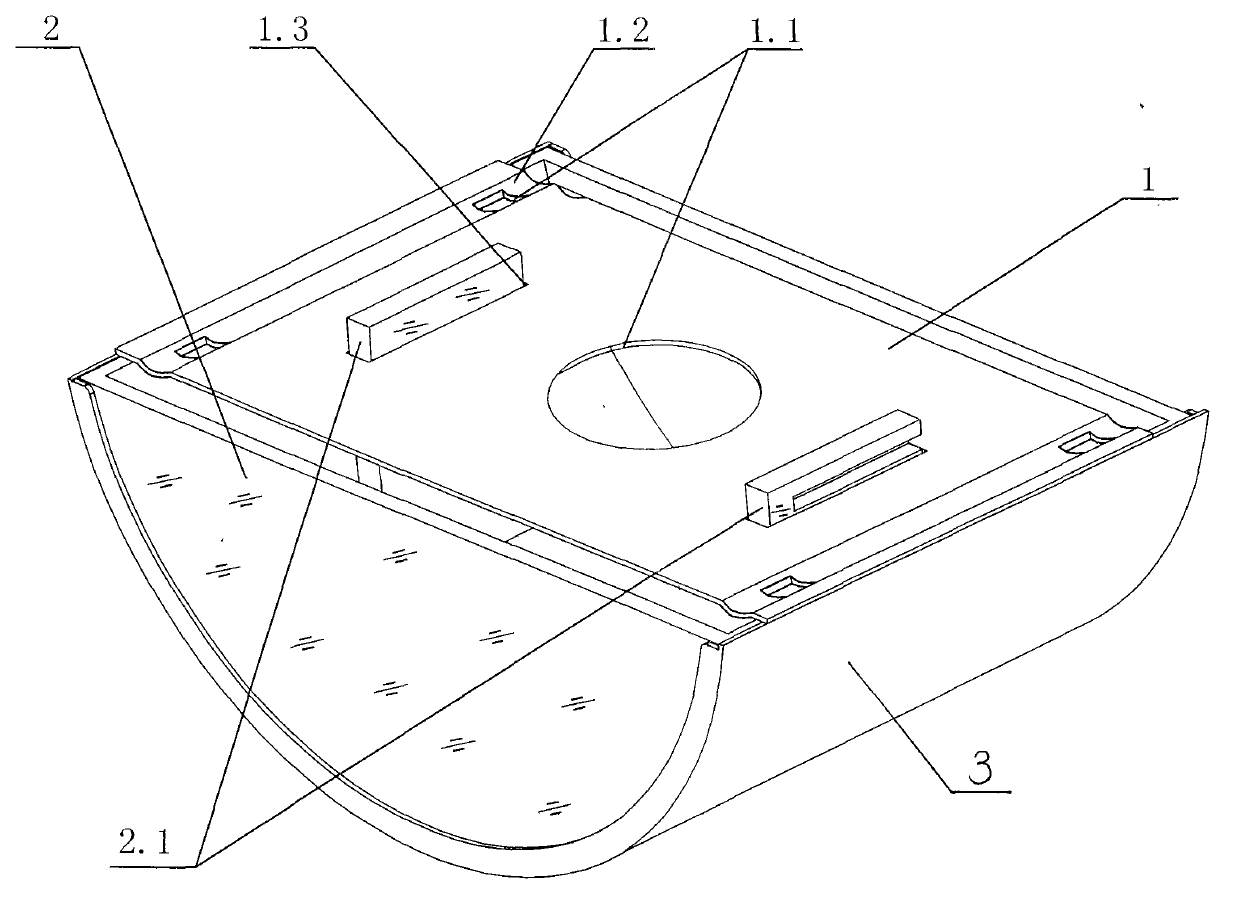

[0007] The implementation process of the binary material composite oil cup of the present invention will be further described below in conjunction with the accompanying drawings:

[0008] (1) Manufacturing process:

[0009] According to the size of the drawing, use a shearing machine to cut a certain length and width of the metal sheet, and then place it on the dies of the support 3 and the support cover 1 installed on the punching machine for stamping, so that the support 3 and the cover 1 The hanging foot hole 1.3 on 1, the groove 1.2, and several oil holes 1.1 are formed at one time; then the cup body 2 (which is wider than the width of the support cover 1) cast and formed according to the drawing is put into the support 3 from above In the process, cover the support cover 1 on it again, so that the two hanging feet 2.1 protrude from the hanging foot holes 1.3 to expose the upper ends of the hanging feet 2.1. Finally, laser welding, grinding and polishing are carried out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com