Waveguide feeder testing and welding device

A technology of welding device and waveguide flange, which is applied in the field of waveguide feeder, can solve the problems of lower product qualification rate, inability to effectively solve the electrical performance and unqualified waveguide feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

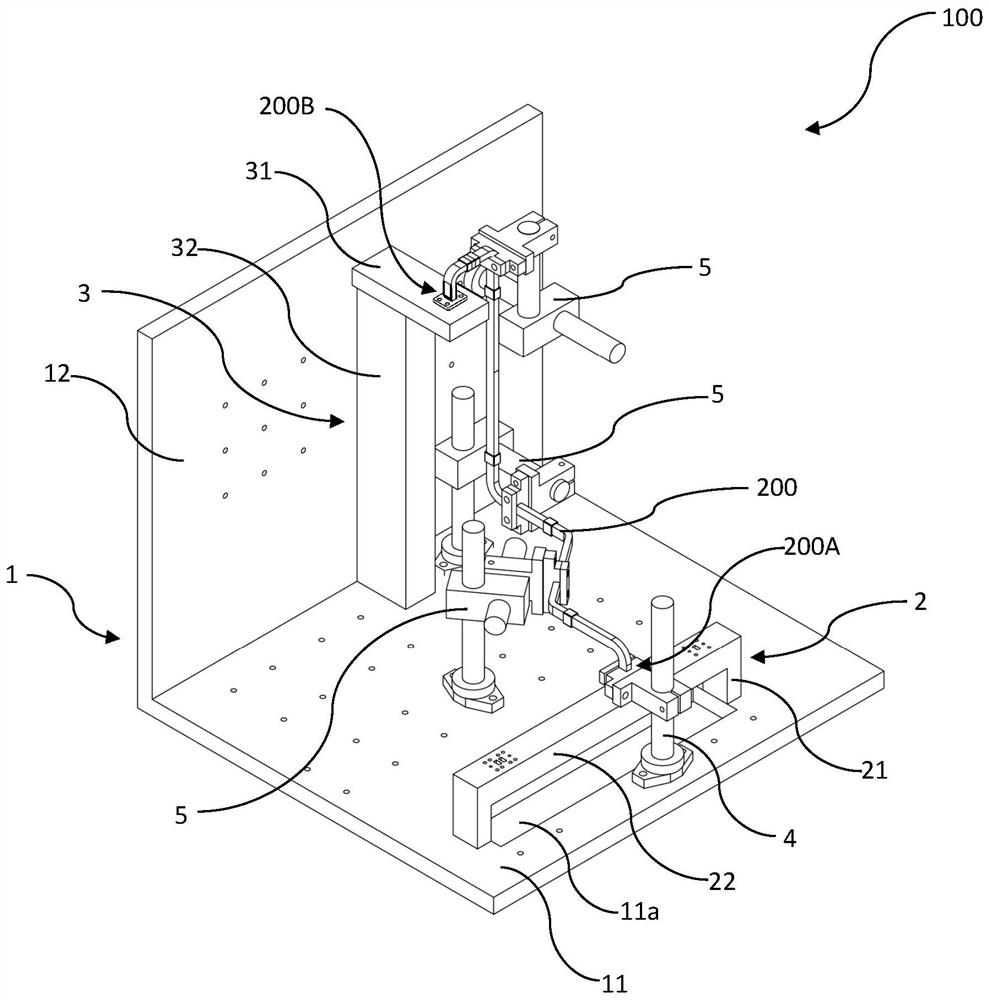

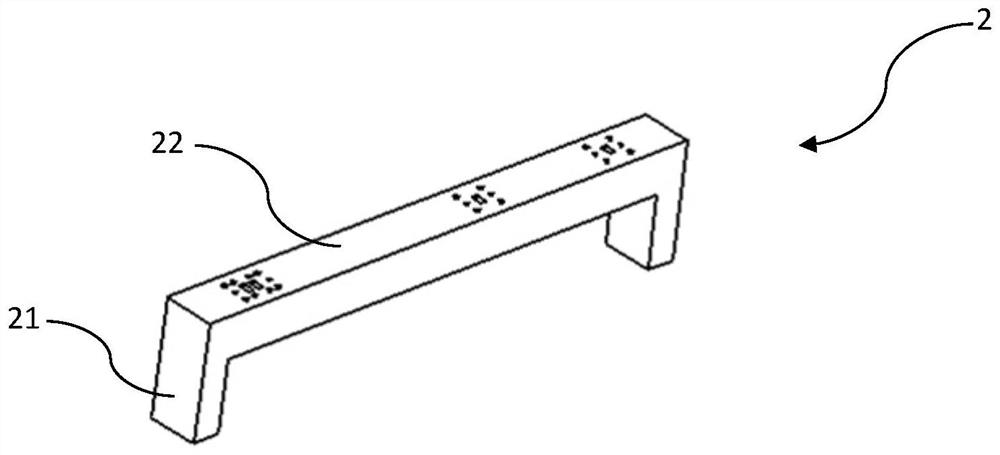

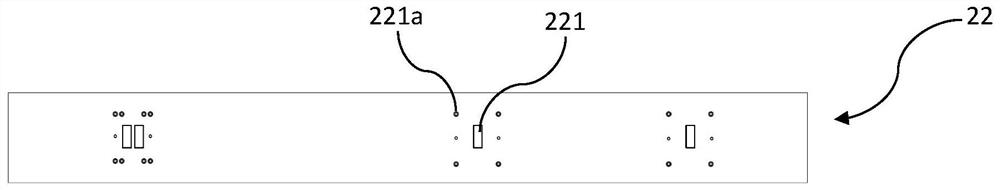

[0026] The specific implementation manners of the present invention will be described below in conjunction with the drawings and embodiments.

[0027] The waveguide feeder in the embodiment of the present invention is strip-shaped, has two ends with waveguide flanges, and is a component formed by connecting a plurality of waveguides with a clamp in the middle.

[0028]

[0029] This embodiment provides a waveguide feeder testing and welding device 100, which is used to fix the waveguide feeder 200 to be tested so as to perform electrical performance testing, welding and dimension inspection. At the end of the flange, the waveguide feeder is connected to external electrical performance testing equipment, and the electrical performance testing equipment has a first coaxial flange and a second coaxial flange for connecting the waveguide feeder to be tested.

[0030] In this embodiment, the electrical performance testing equipment is Yanetics.

[0031] figure 1 It is a structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com