Aluminium alloy section bar and the slide door and window made thereof

A technology of aluminum alloy profiles, sliding doors and windows, applied in the direction of the arrangement of the wing fan, etc., can solve the problems of ineffective dust prevention, small arc surface area at the top, small diameter of mushroom surface, etc., to achieve the best anti-mosquito effect, smooth sliding and smooth Strong, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

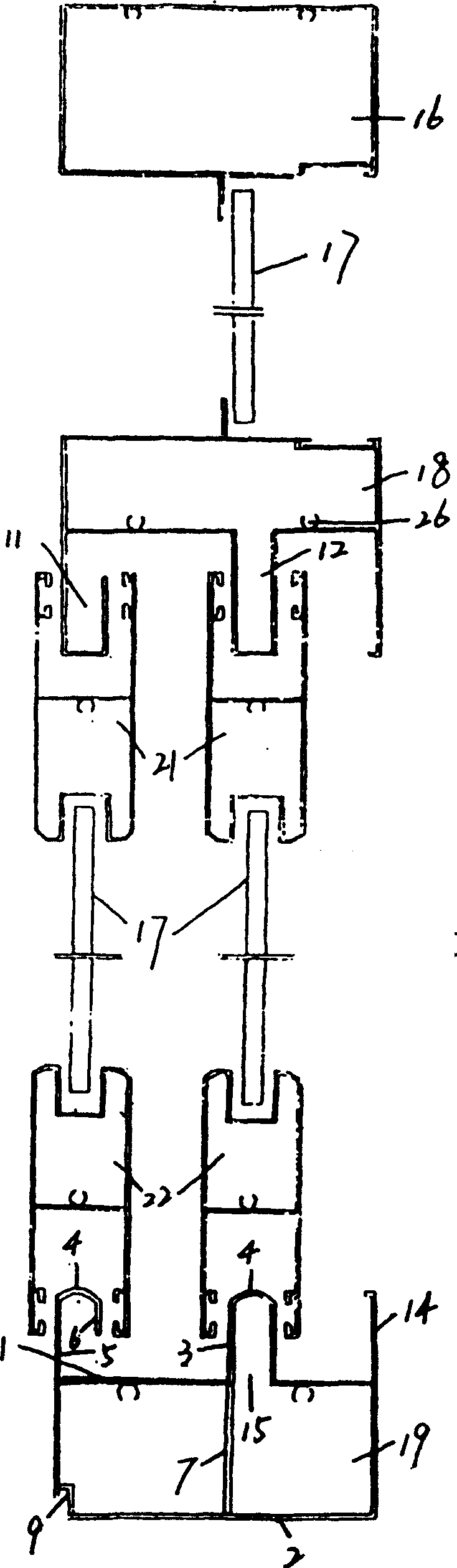

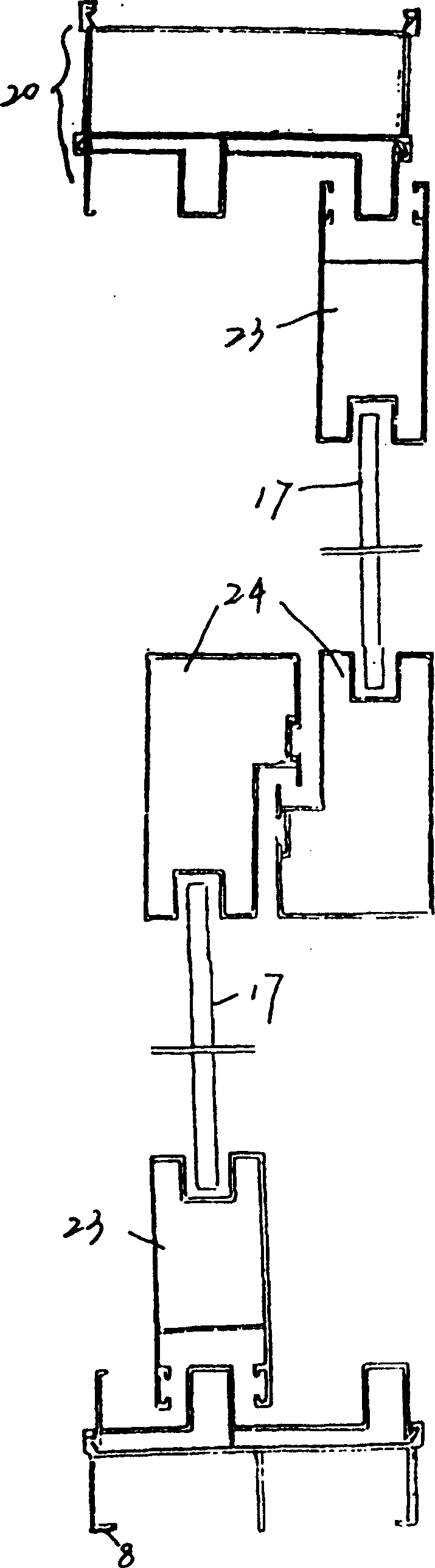

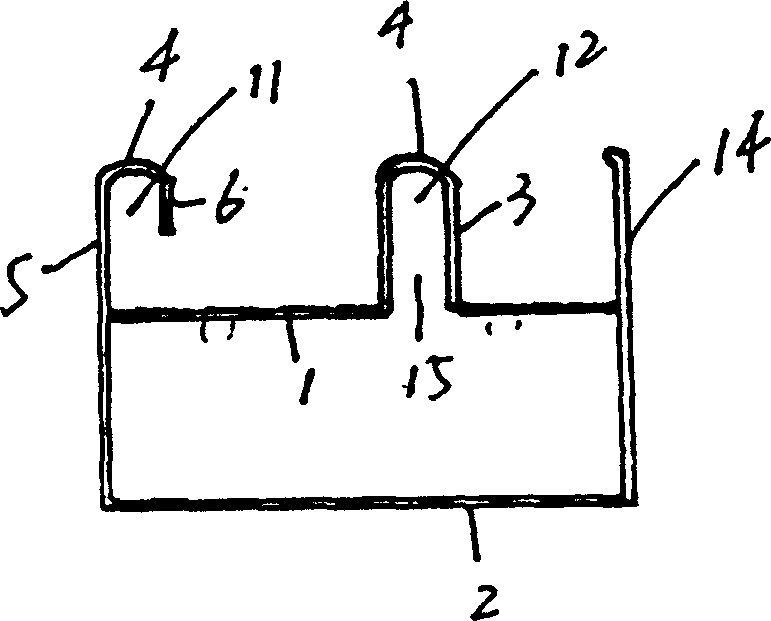

[0021] figure 1 , figure 2 The aluminum alloy sliding doors and windows shown are composed of upper fixing 16, upper rail 18, lower rail 19, edge seal 20, upper 21, lower 22, light opening 23, hook opening 24, screen material, upper fixing 16, upper rail 18 and lower rail 19 are arranged in parallel according to the required spacing, and their two ends are respectively embedded in the specified parts of the two side seals 20, and fixedly connected with screws, or connected with the specified parts of the connecting corner pieces and the two side seals 20 with screws, between the upper fixing 16 and the upper track 18 Embed glass 17 to make the outer frame of aluminum alloy sliding doors and windows; the two ends of the upper part 21 and the lower part 22 are respectively embedded with the two ends of the optical part 23 and the hook part 24, and are fixed and connected with screws, or using connecting corner pieces or screws Fixed connection, glass 17 is embedded between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com