Plate-mounting device

A technology for installing devices and printing plates, which is applied in printing, printing machines, printing processes, etc., and can solve problems such as difficult installation of plate-shaped printing plates, position deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

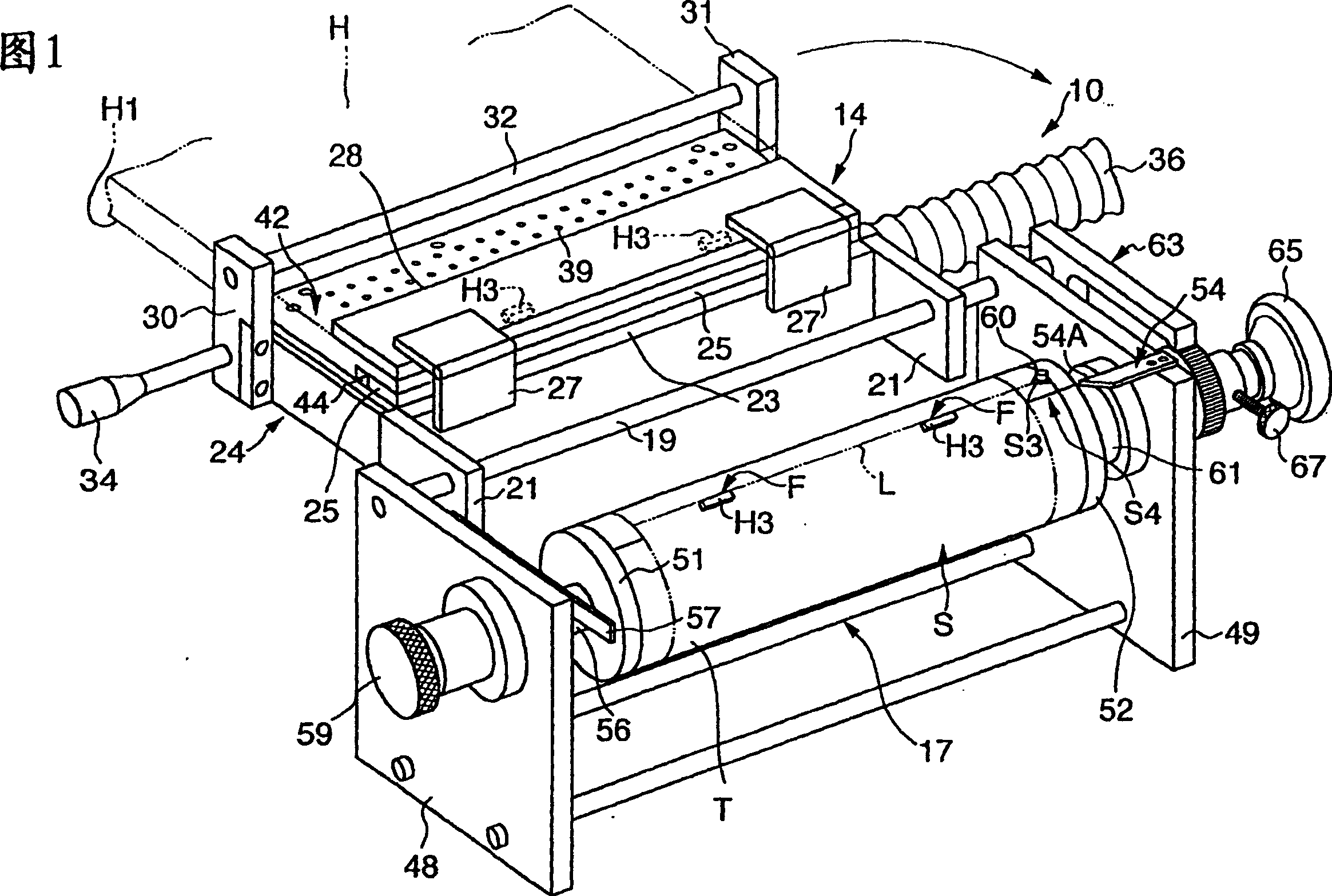

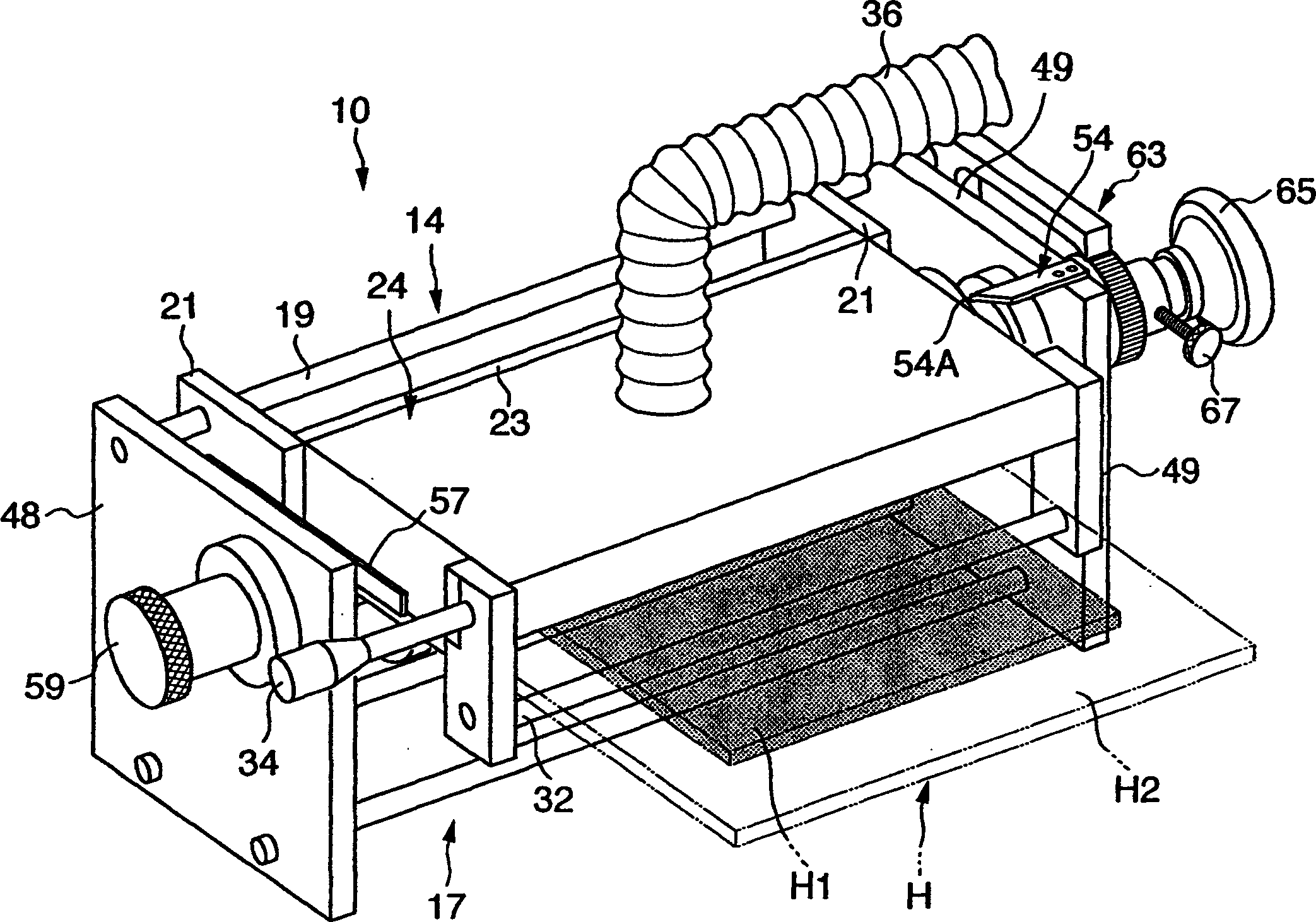

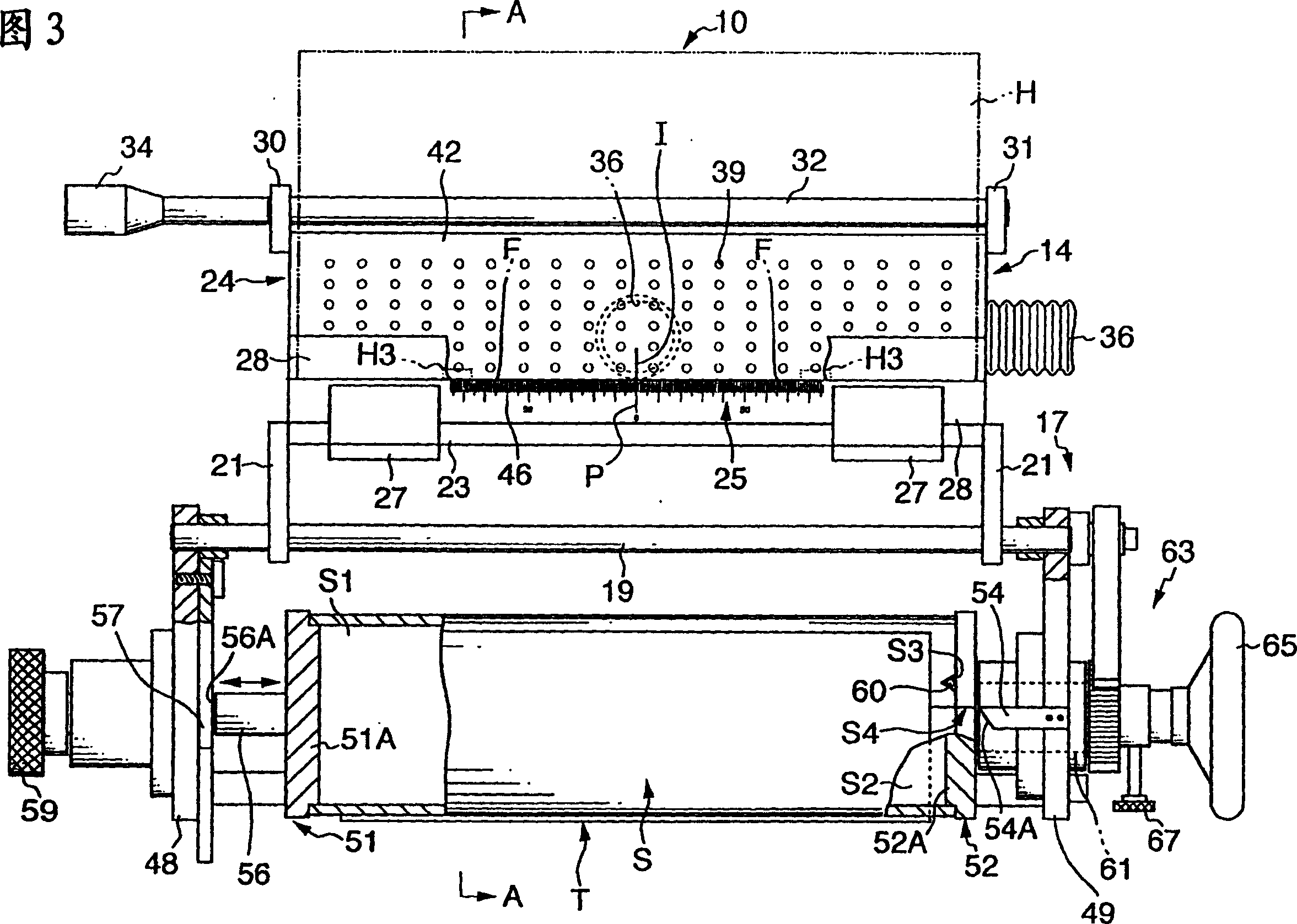

[0017] FIG. 1 is a schematic perspective view of a state of a printing plate mounting apparatus 10 according to the present invention. figure 2 is a schematic perspective view of another state of the printing plate mounting device 10 . FIG. 3 is a schematic plan view of the printing plate mounting device 10 shown in FIG. 1 . Figure 4 is a sectional view of the plate mounting apparatus 10 taken along line A-A of FIG. 3 , wherein a part of the apparatus shown in FIG. 3 is omitted. The printing plate mounting device 10 shown in these figures is a device for mounting a printing plate H on the outer peripheral surface of a printing plate cylinder S which has been printed from a printing machine (not shown). Remove from the device. The printing plate mounting device 10 has a printing plate setting portion 14 for holding the printing plate H, and a printing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap