Electromagnetic brake

An electromagnetic brake and movement technology, applied in the direction of brake types, drum brakes, brake components, etc., can solve problems such as difficulty in clamping shock absorbing pads, reduced attractive force, and complex collision surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

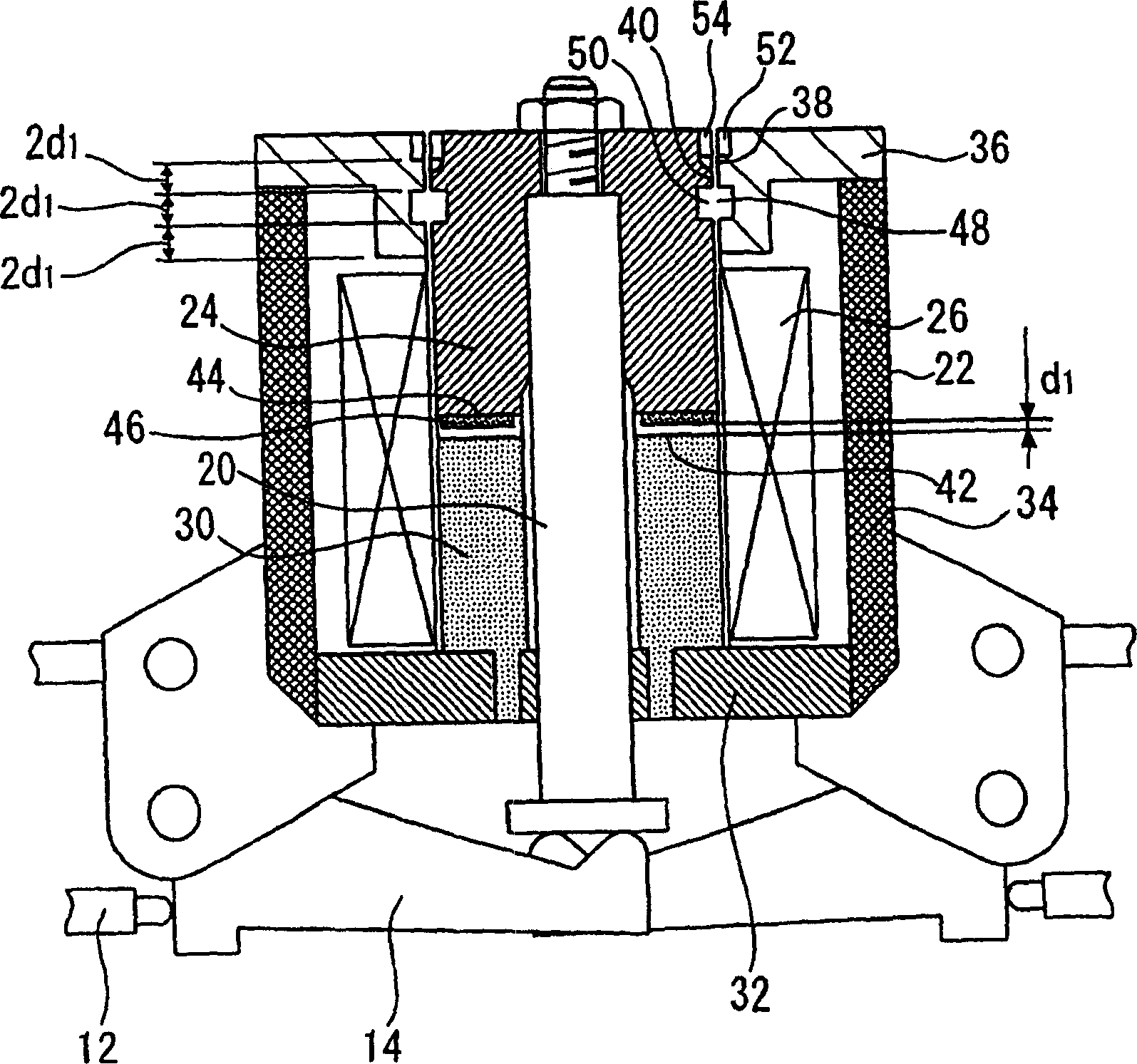

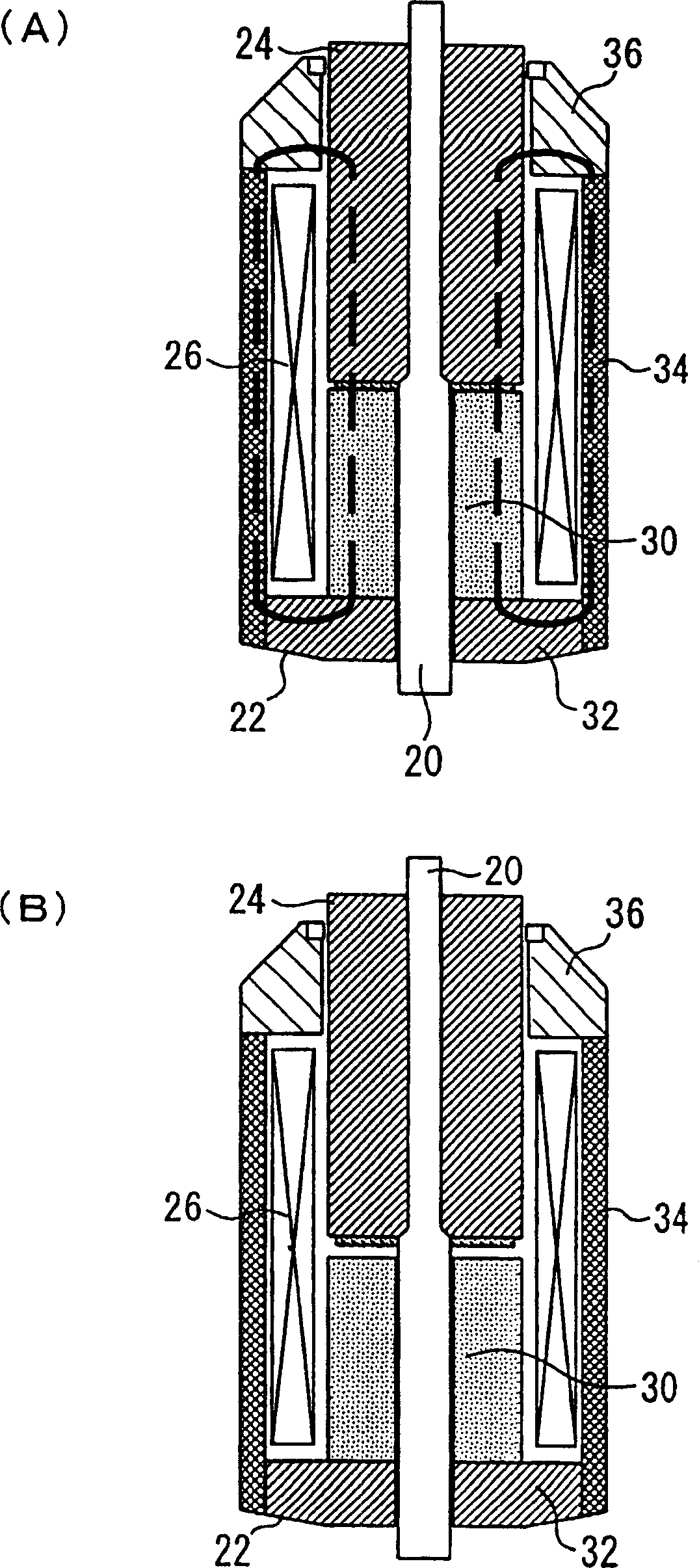

[0027] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In addition, in each figure, the same code|symbol is attached|subjected to the same or corresponding part, and the description is simplified or omitted.

[0028] First, from Figure 1 to Figure 8 Embodiment 1 of the present invention will be described.

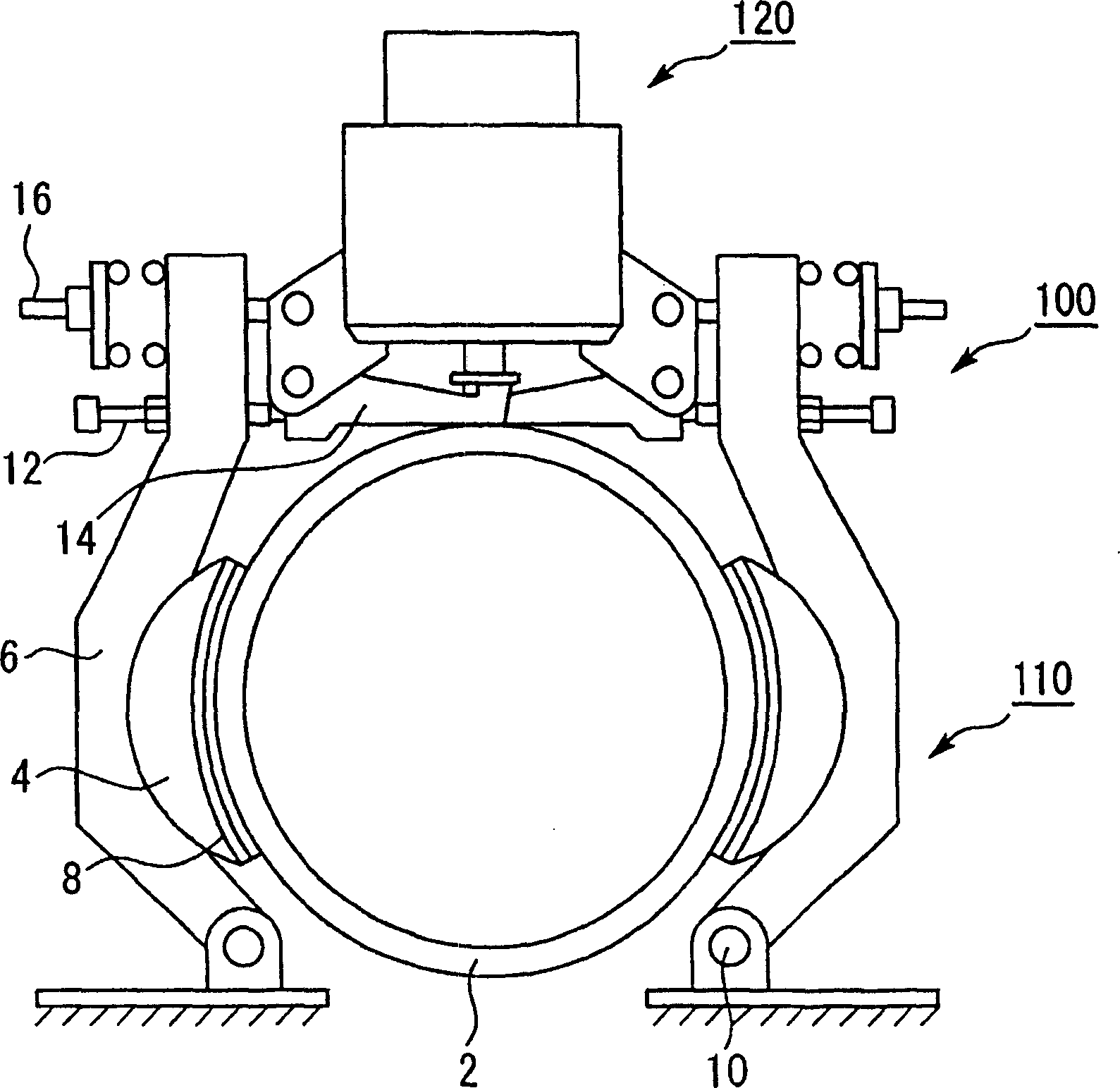

[0029] figure 1 It is a front view illustrating the brake 100 for a hoist according to Embodiment 1 of the present invention.

[0030] Such as figure 1 As shown, the brake 100 for a hoist has a brake mechanism 110 and a plunger type solenoid valve 120 .

[0031] The brake mechanism 110 is composed of a brake drum 2 , a brake pad 4 , and a brake arm 6 .

[0032] The brake drum 2 is attached to a motor shaft (not shown) of the brake 100 for a hoist. The brake drum 2 is a circular cylindrical body viewed from the front. The brake pads 4 are disposed opposite to each other at two opposing places on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com