Cylinder structure of engine

A cylinder block and engine technology, which is applied in the direction of engine lubrication, engine components, machine/engine, etc., can solve the problems of engine width increase, achieve the effects of inhibiting wear, reducing contact pressure, and increasing the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the descriptions of the dimensions, materials, shapes, and relative positions of the structural components involved in this embodiment, unless otherwise specified, are not intended to limit the present invention, but are merely illustrative.

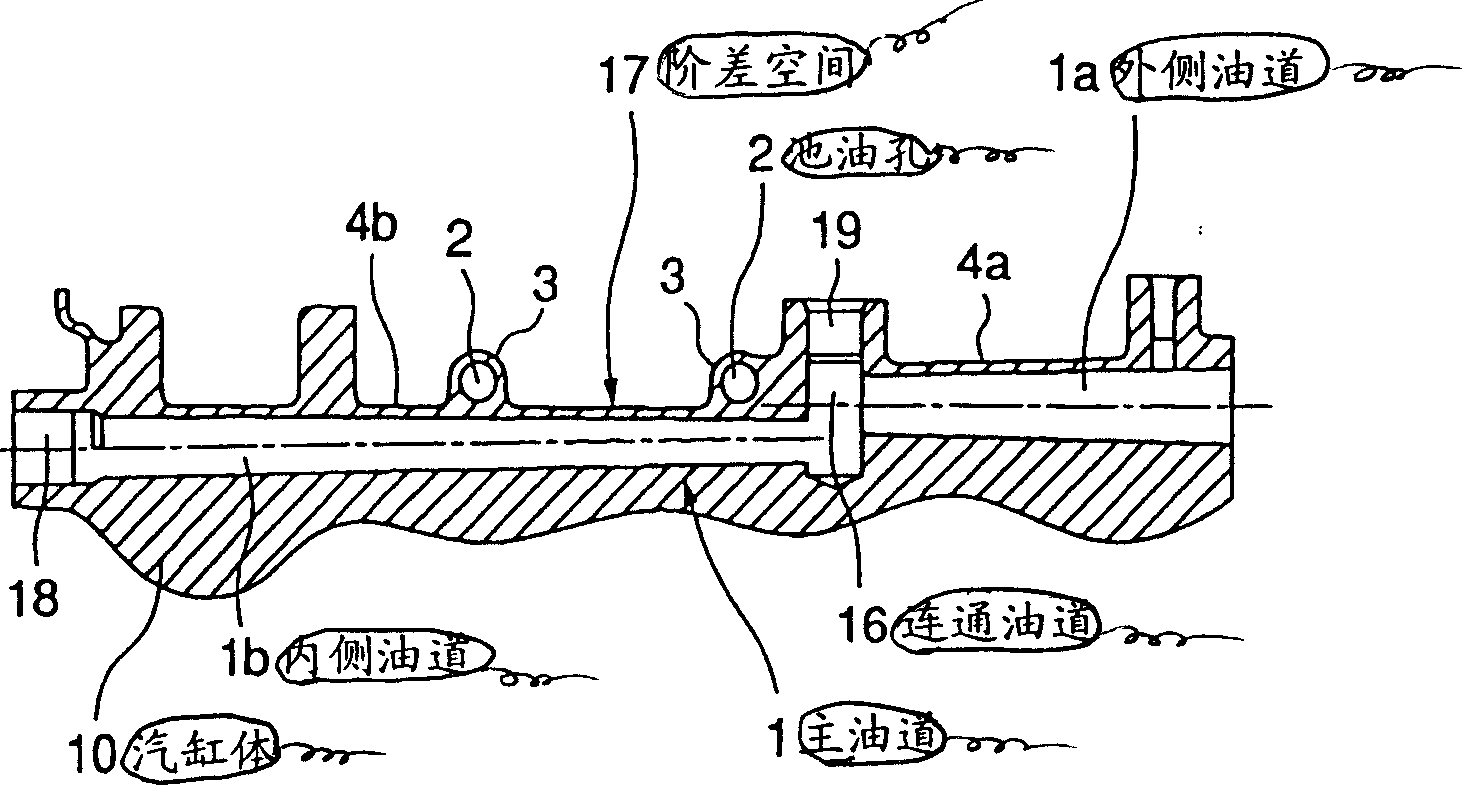

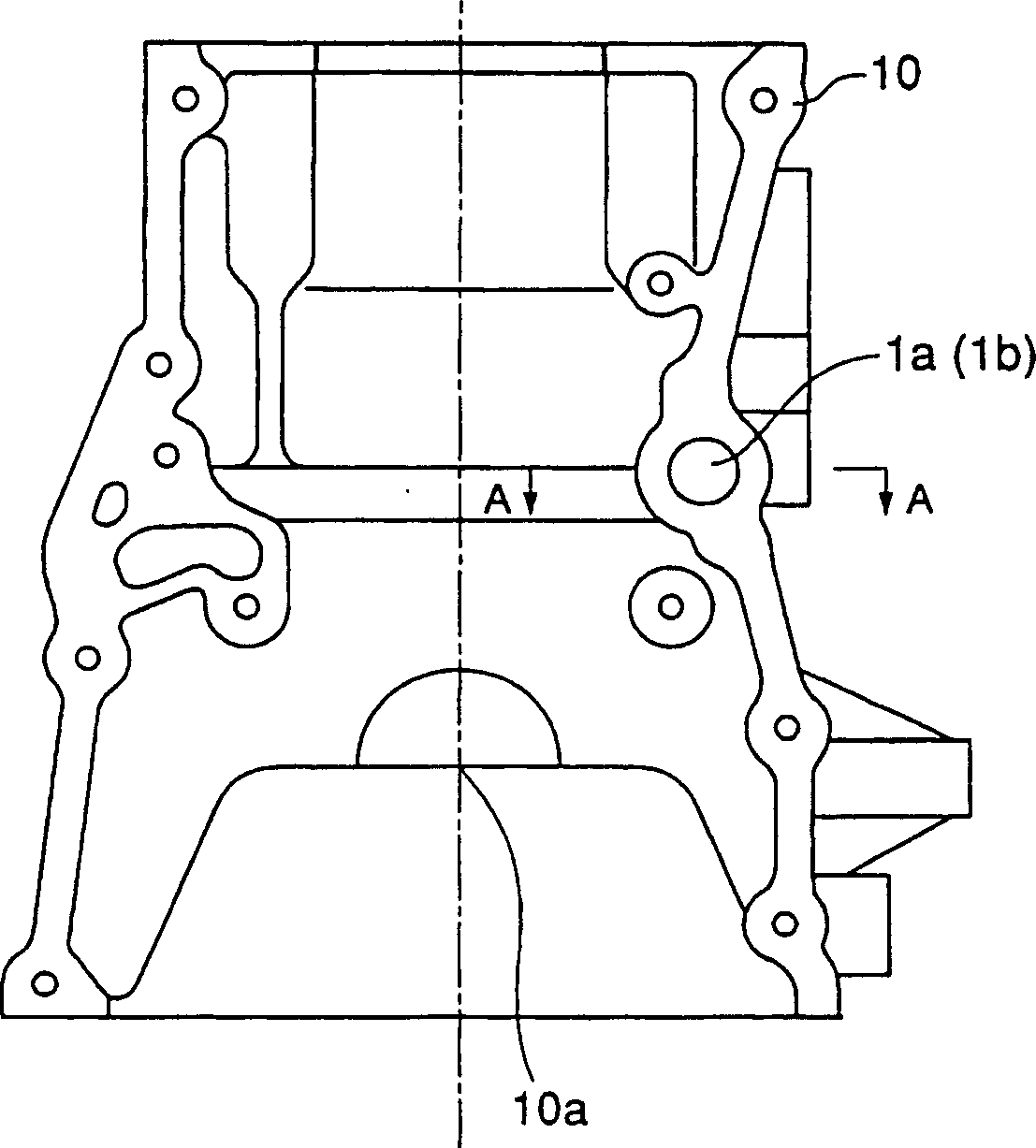

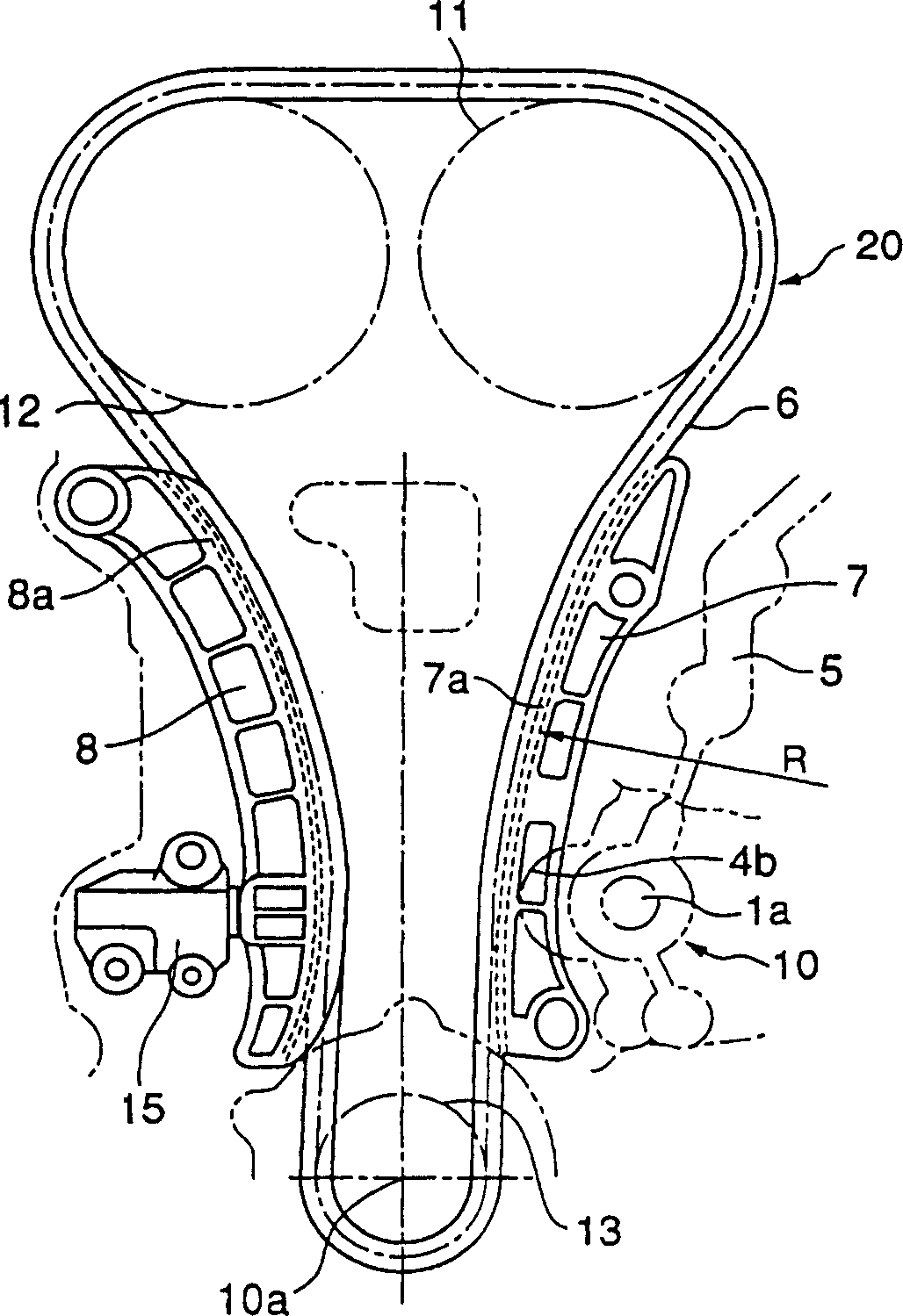

[0031] figure 1 is a cross-sectional view of a main oil passage in an engine cylinder block according to an embodiment of the present invention ( figure 2 sectional view of line A-A), figure 2 It is an end view viewed from the direction of the crankshaft axis of the cylinder block. image 3 This is a front view from the direction of the crankshaft axis of the timing chain device.

[0032] image 3 The timing chain device according to the preferred embodiment of the present invention is given, in the figure, 5 represents the timing chain cover, which is installed in the image 3 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com