High-pressure piston cylinder and high-pressure transportation pump of internal-combustion engine

A high-pressure conveying, high-pressure piston technology, applied in the components of the pumping device for elastic fluid, fuel injection pump, fuel injection device, etc., can solve the problem of the danger of piston seizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

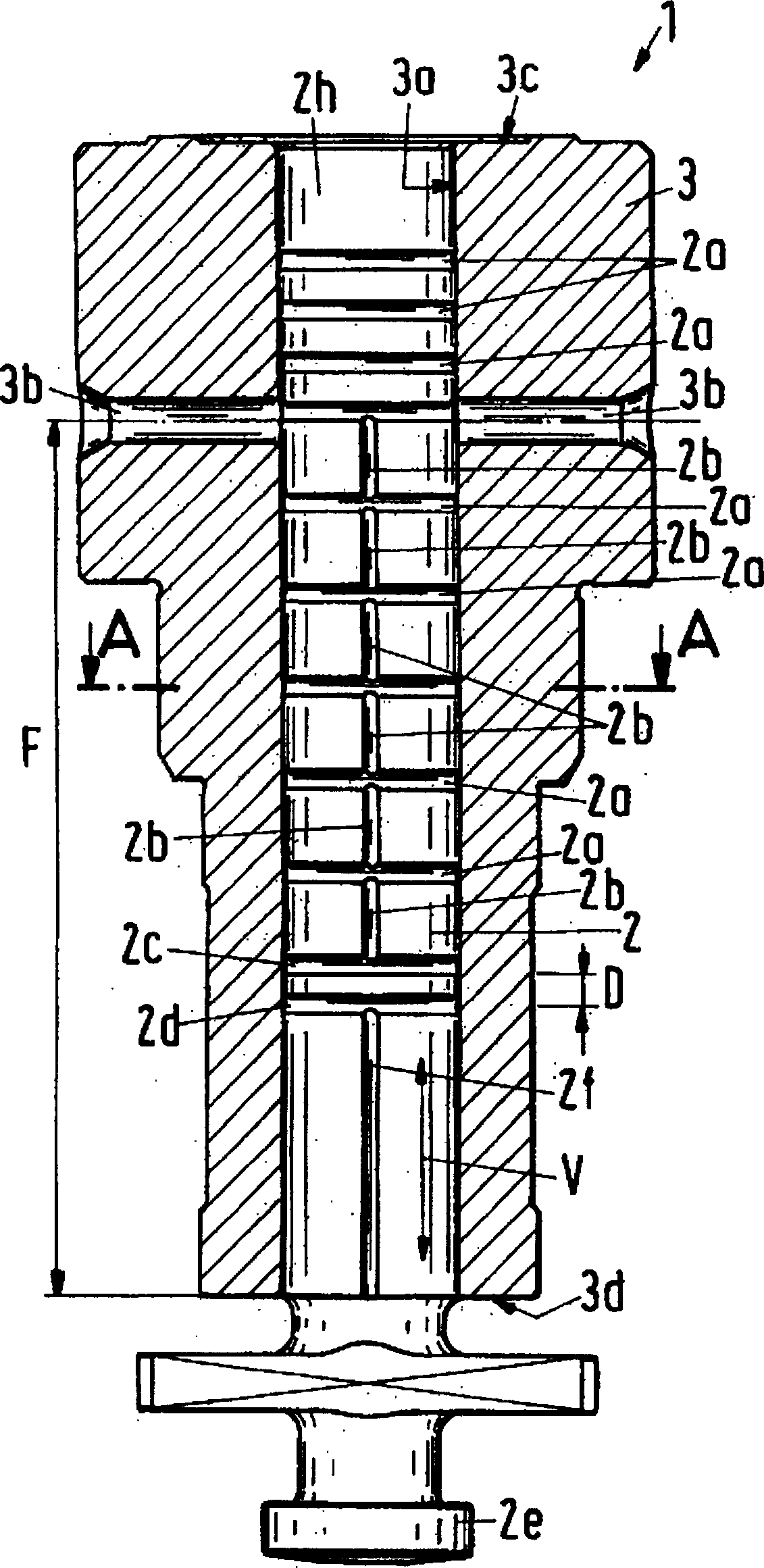

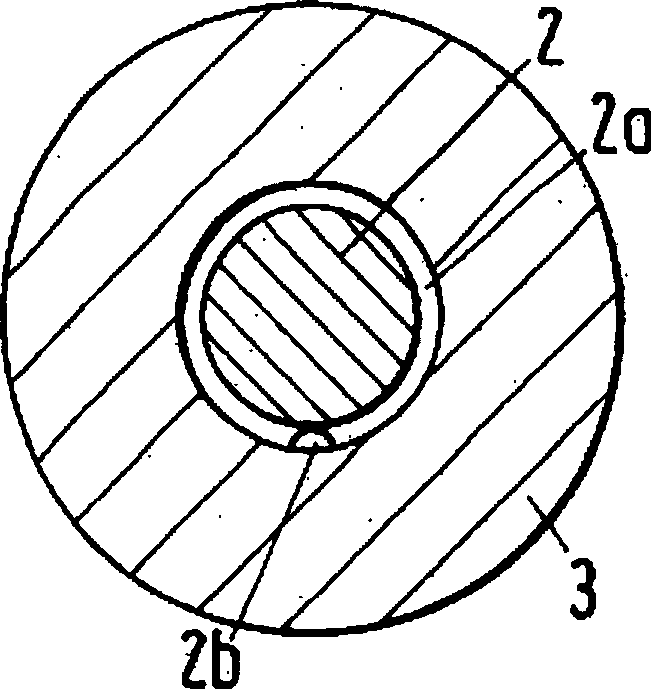

[0023] figure 1 A high-pressure piston-cylinder arrangement is shown, which comprises a cylinder 3 with a cylinder 3a and a piston 2 that is guided in the direction of movement V in the cylinder. Two fuel supply ports 3b open into the cylinder 3a. The piston 2 compresses the fuel flowing in through the fuel supply port 3b in the direction toward the high-pressure side 3c of the cylinder 3 . Atmospheric pressure preferably acts on the opposite cylinder 3 low-pressure side 3d.

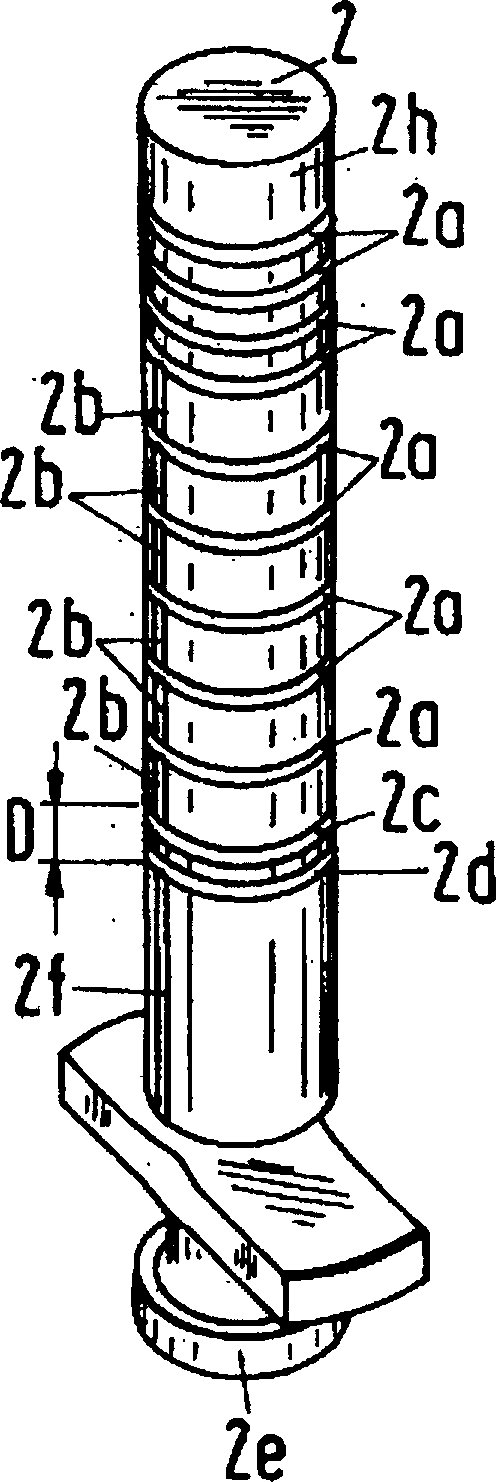

[0024] Such as figure 1 shown and see figure 2 The perspective view, the outer surface of the cylinder 3 has a first transverse groove 2c and a second transverse groove 2d, which are spaced apart from each other by a sealing length D. Such as figure 1 As shown, these transverse grooves 2c, 2d are arranged such that at any position of the piston reciprocating in the cylinder 3a, the transverse grooves are located between the fuel supply port 3b and the low pressure port 3d. The first transverse gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com