Bidirectional drive orienting output wheel

A two-way drive, output wheel technology, applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve the problem that the output wheel can only be driven forward in one direction, and achieve the effect of balanced movement and exercise, easy operation, and fatigue relief.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

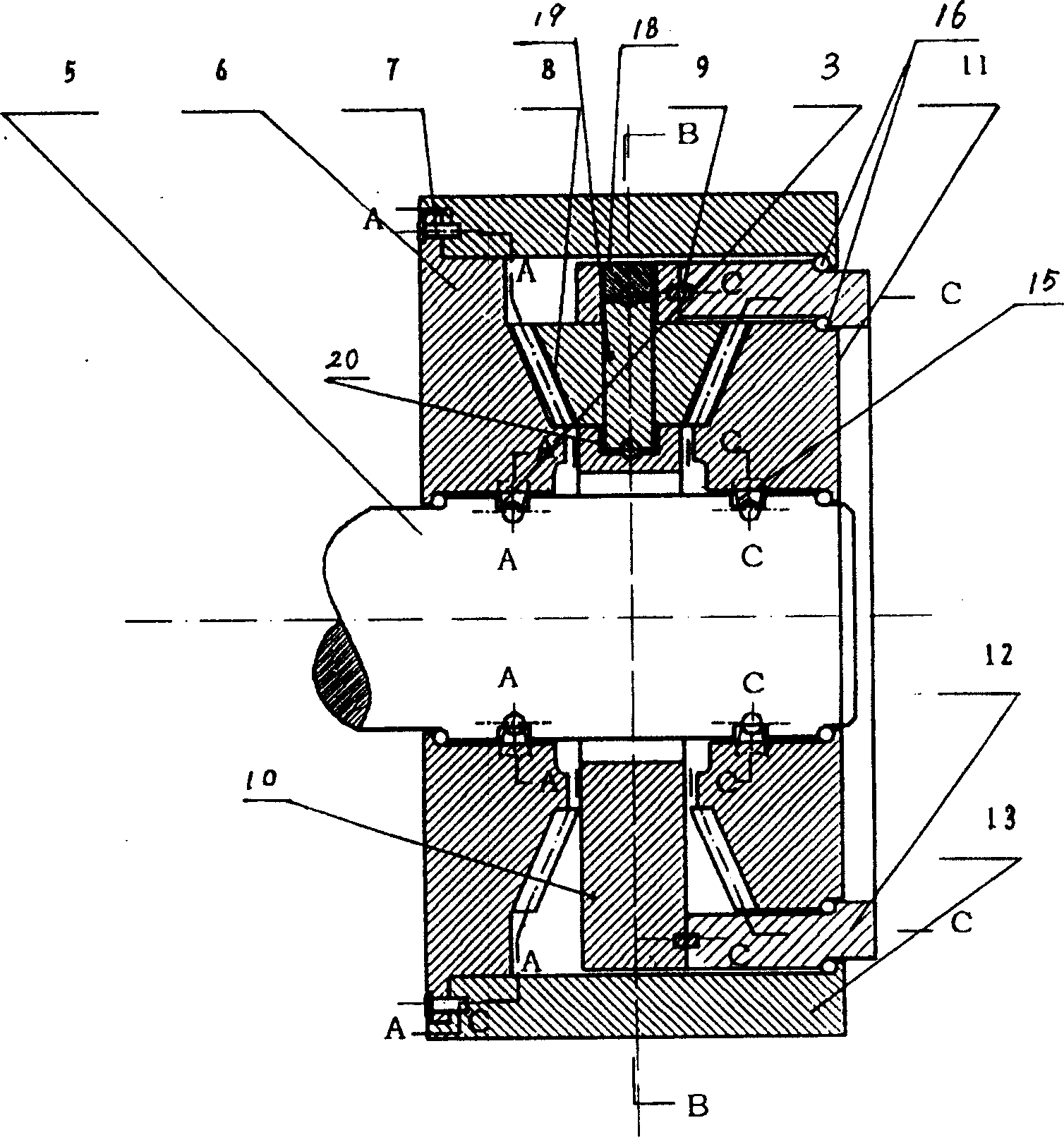

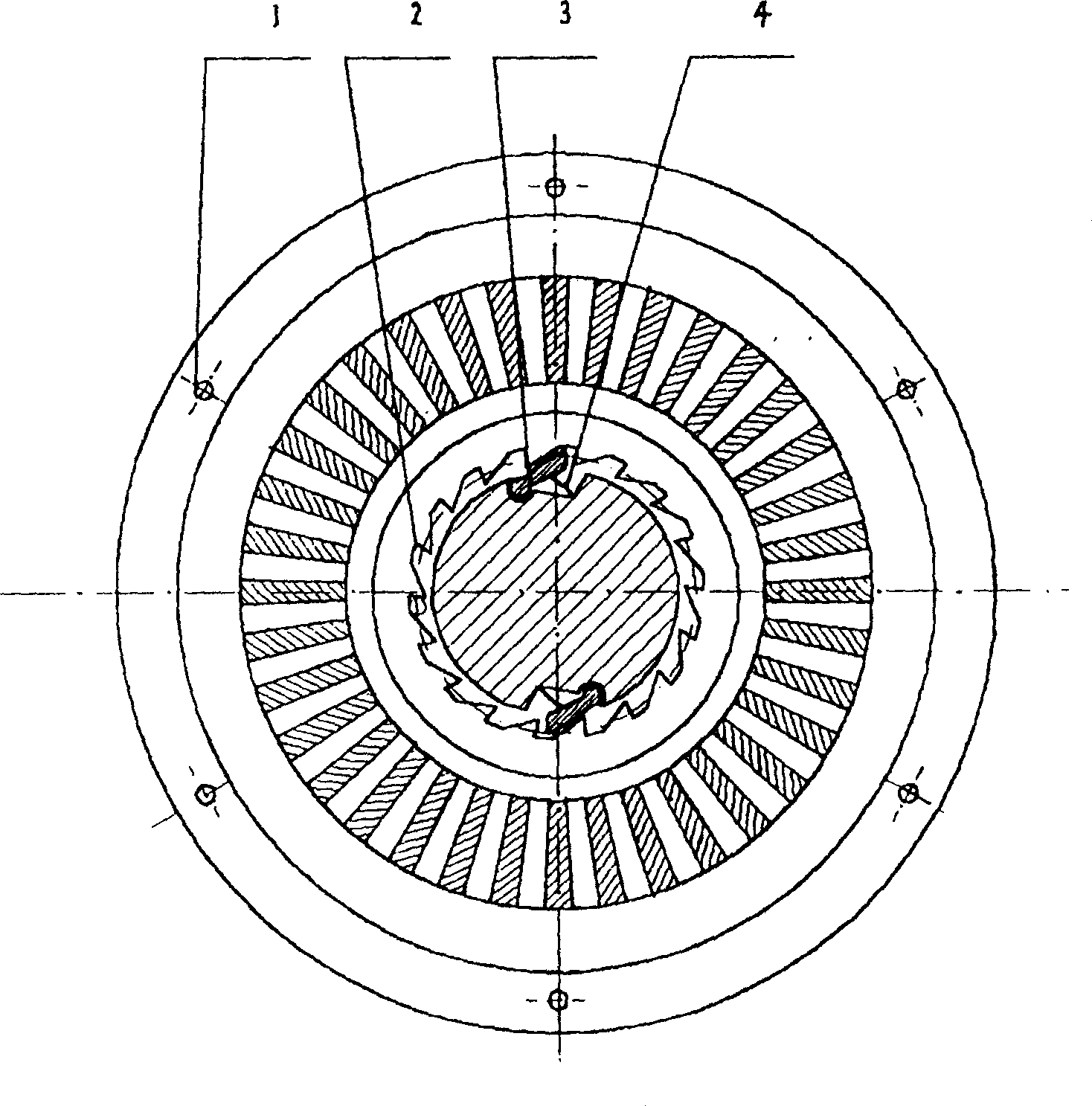

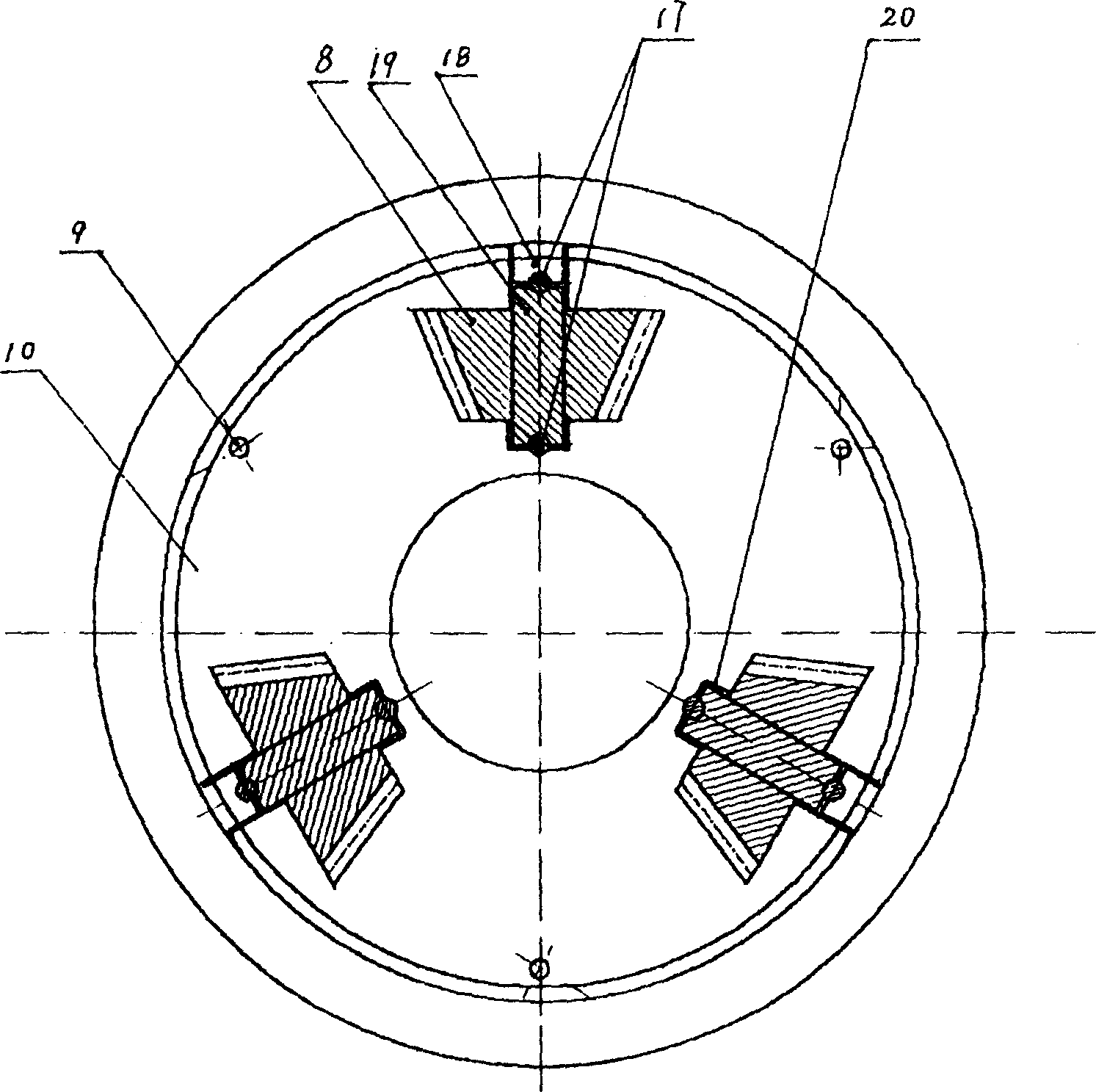

[0021] like Figure 1~4 As shown, the present invention consists of screw hole 1, first ratchet 2, first pawl 3, spring leaf 4, output shaft 5, first compound gear 6, bolt 7, bevel gear 8, fixed pin 9, disc 10 , the second composite gear 11, the fixed cylinder 12, the wheel body 13, the second ratchet 14, the second pawl 15, the ball bearing 16, the ball 17, the plunger 18, the rotating shaft 19 and the like. On the output shaft 5, the first compound gear 6 and the second compound gear 11 are oppositely arranged, and rolling bearings 16 are respectively installed between the output shaft 5 and the first and second compound gears 6, 11. One side of the first and second compound gears 6, 11 Conical teeth are respectively provided, and the tooth surfaces are opposite to each other. First and second ratchets 2 and 14 are provided on the inner walls of the first and second compound gears 6 and 11 respectively. 15 grooves, the spring leaf 4 supporting the ratchet is housed in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com