Non-return valve with large-sized outlet

A check valve, size technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve difficult, impossible and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

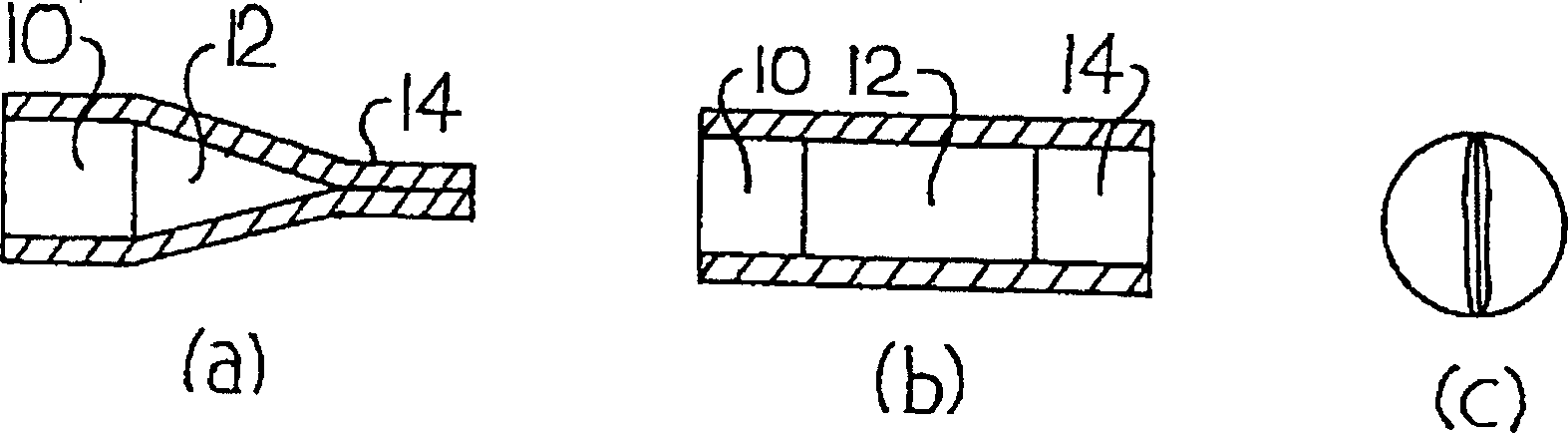

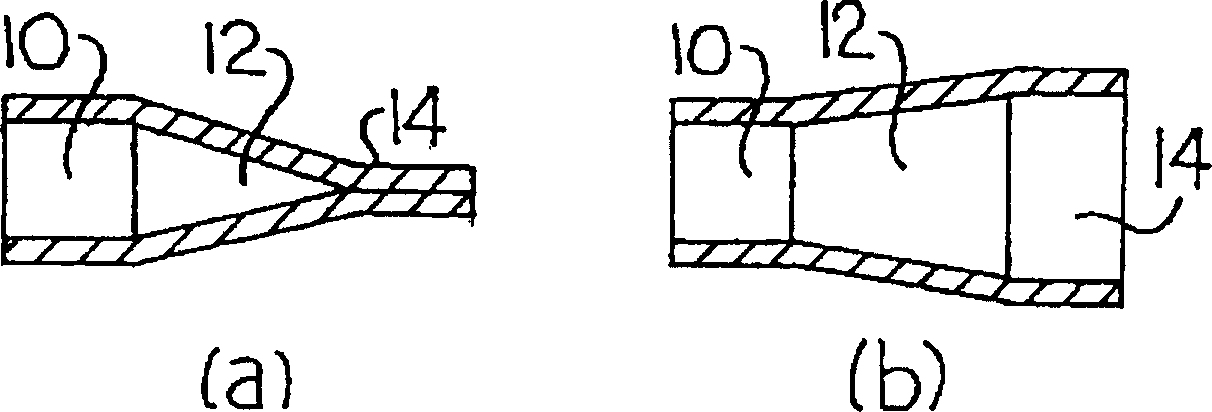

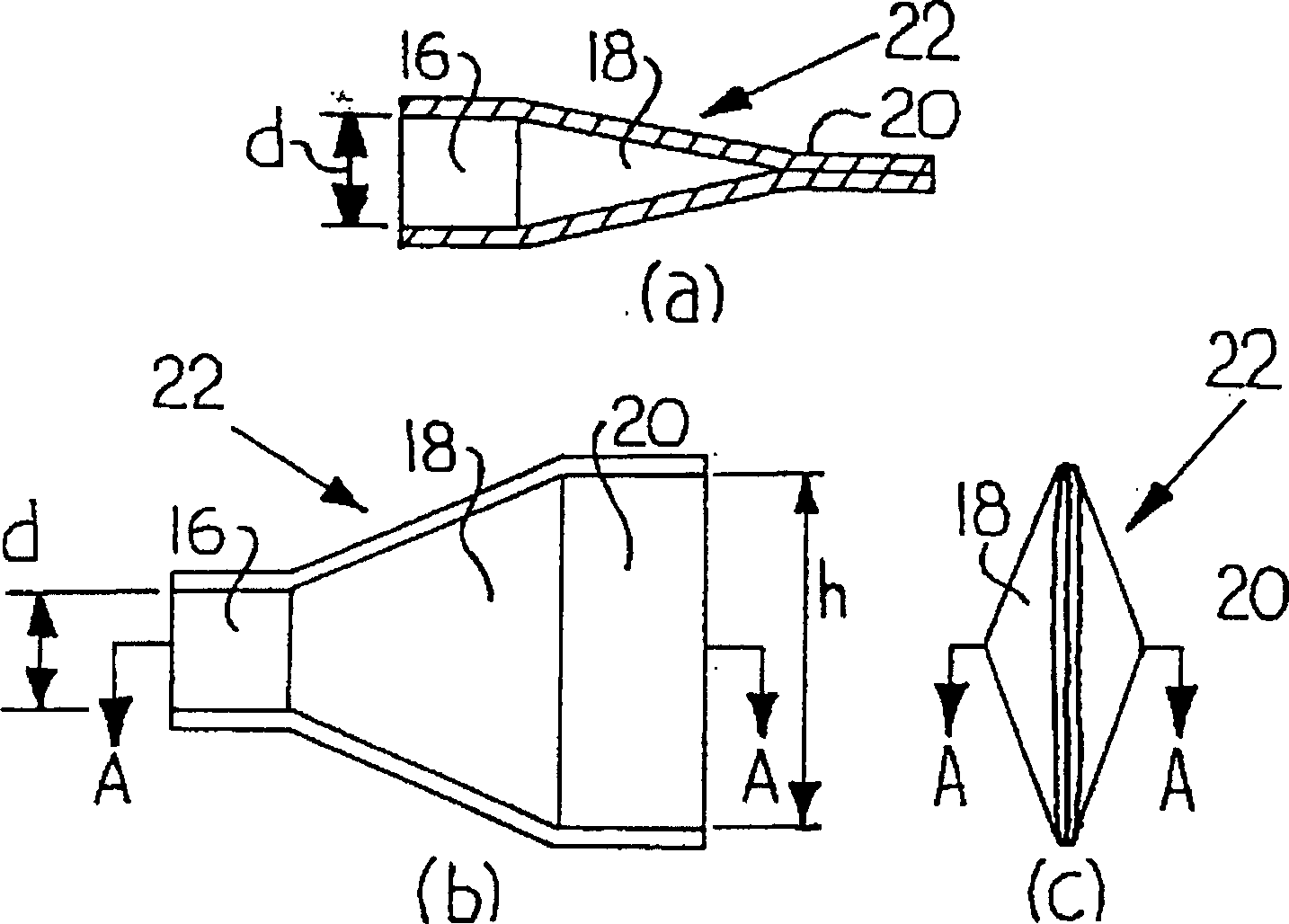

[0023] attached figure 1 and 2 A conventional duckbill check valve is shown. These valves include an inlet section 10 , a transition section 12 and an outlet section 14 . The advantage of this design is that machining costs are low and the mandrel can be easily removed from the entire part. attached figure 2 The check valve shown in is slightly widened, with the width of the outlet portion 14 approximately equal to half the circumference of the inlet portion 10 . It is slightly more difficult to remove the mandrel completely from the valve, but the head loss is low.

[0024] After extensive testing at the University of Utah Water Research Laboratory, for submerged outflow, the head loss of a "duckbill" check valve is very close to:

[0025] H=Q 2 / 19.5gA 2

[0026] where H = head loss in feet of water,

[0027] Q = the number of gallons of water flowing through it per minute,

[0028] g = gravitational constant = 32.16 ft / s 2 ,and

[0029] A = effective open area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com