Solid bowl helical conveyor centrifuge with a pressurized housing

A technology of screw conveying and non-porous drum, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of increasing driving power, increasing power consumption of centrifuges, heating of gas and rotating parts, etc. The effect of preventing electric shock, lowering of cooling equipment, lowering of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

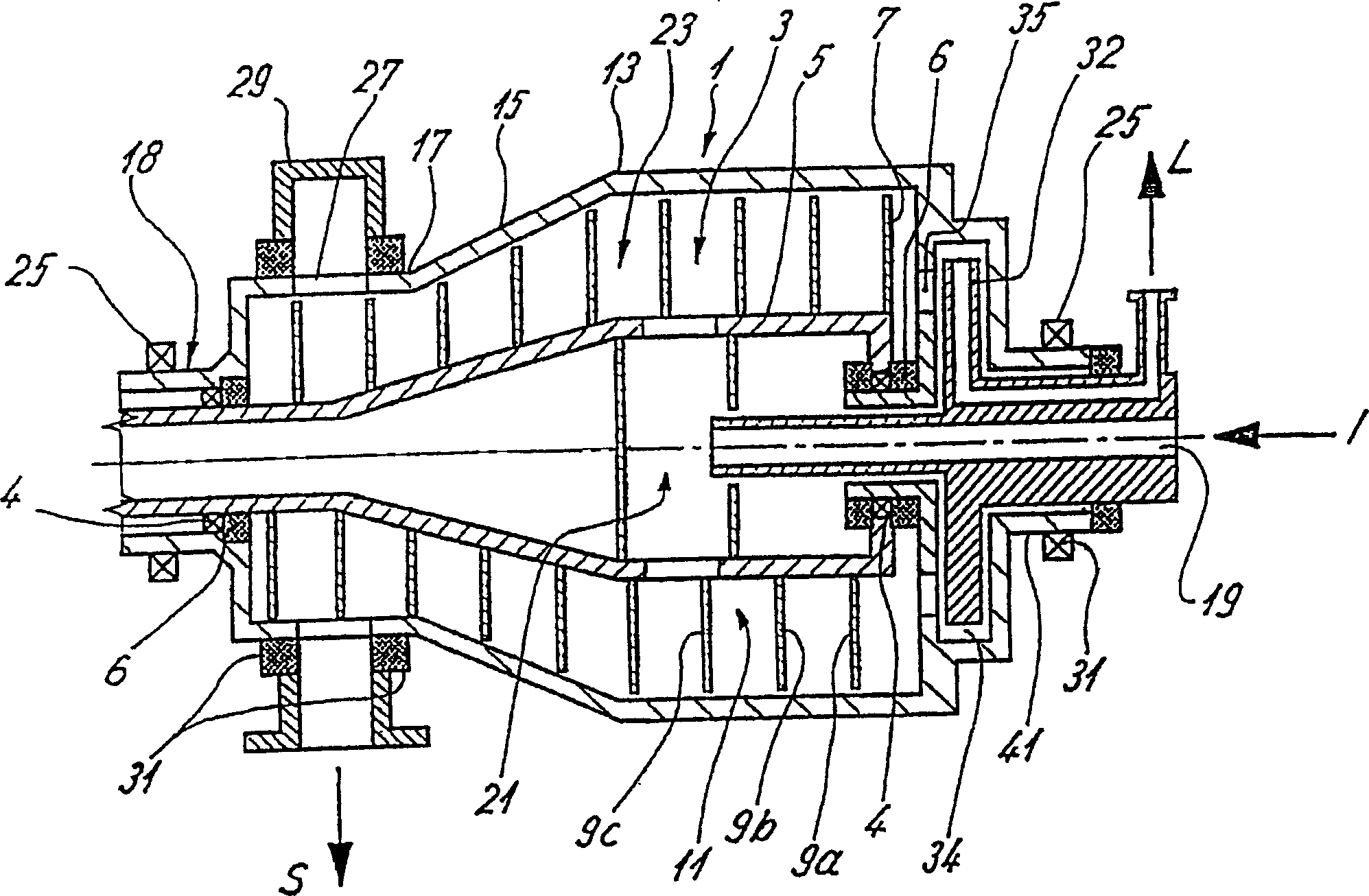

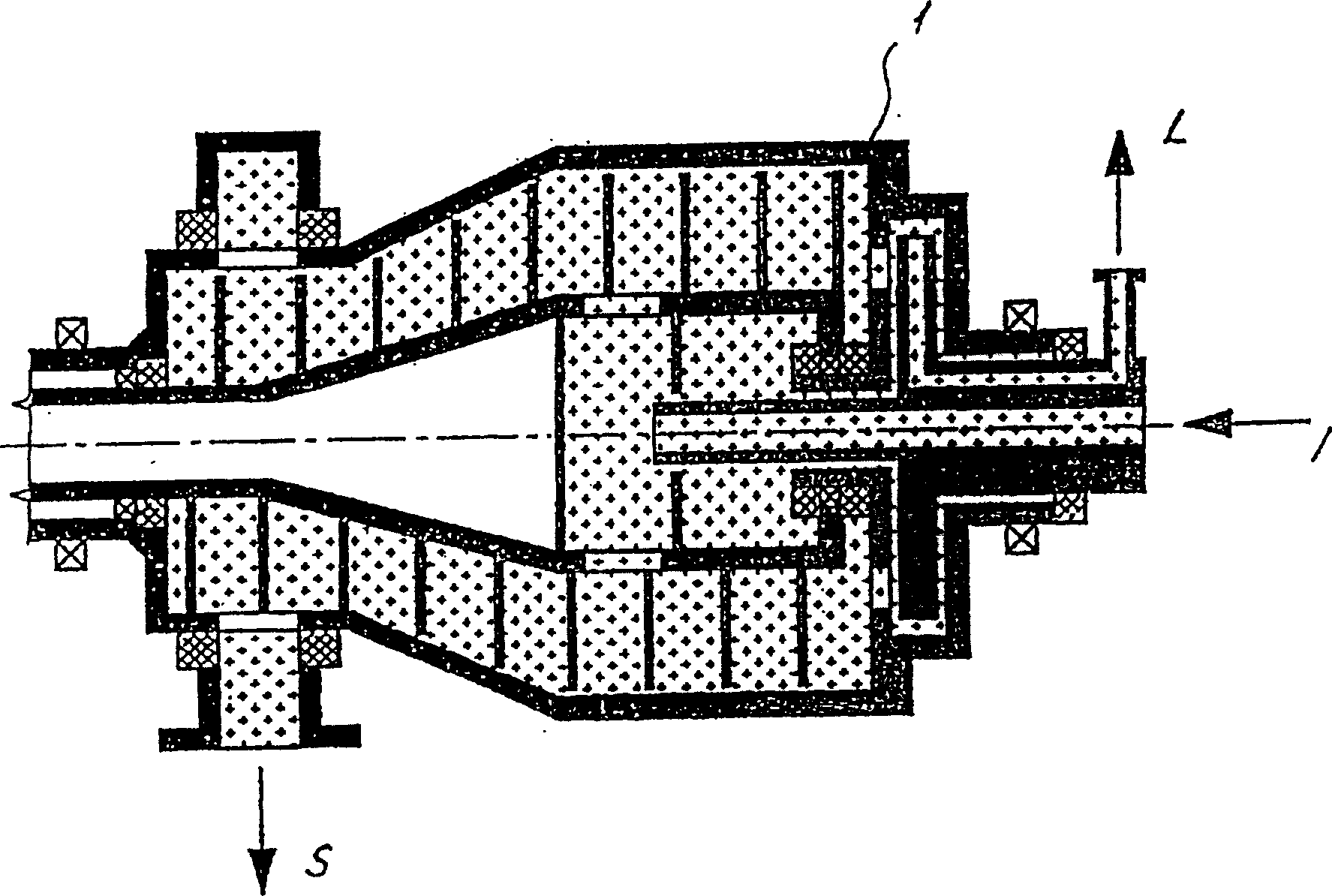

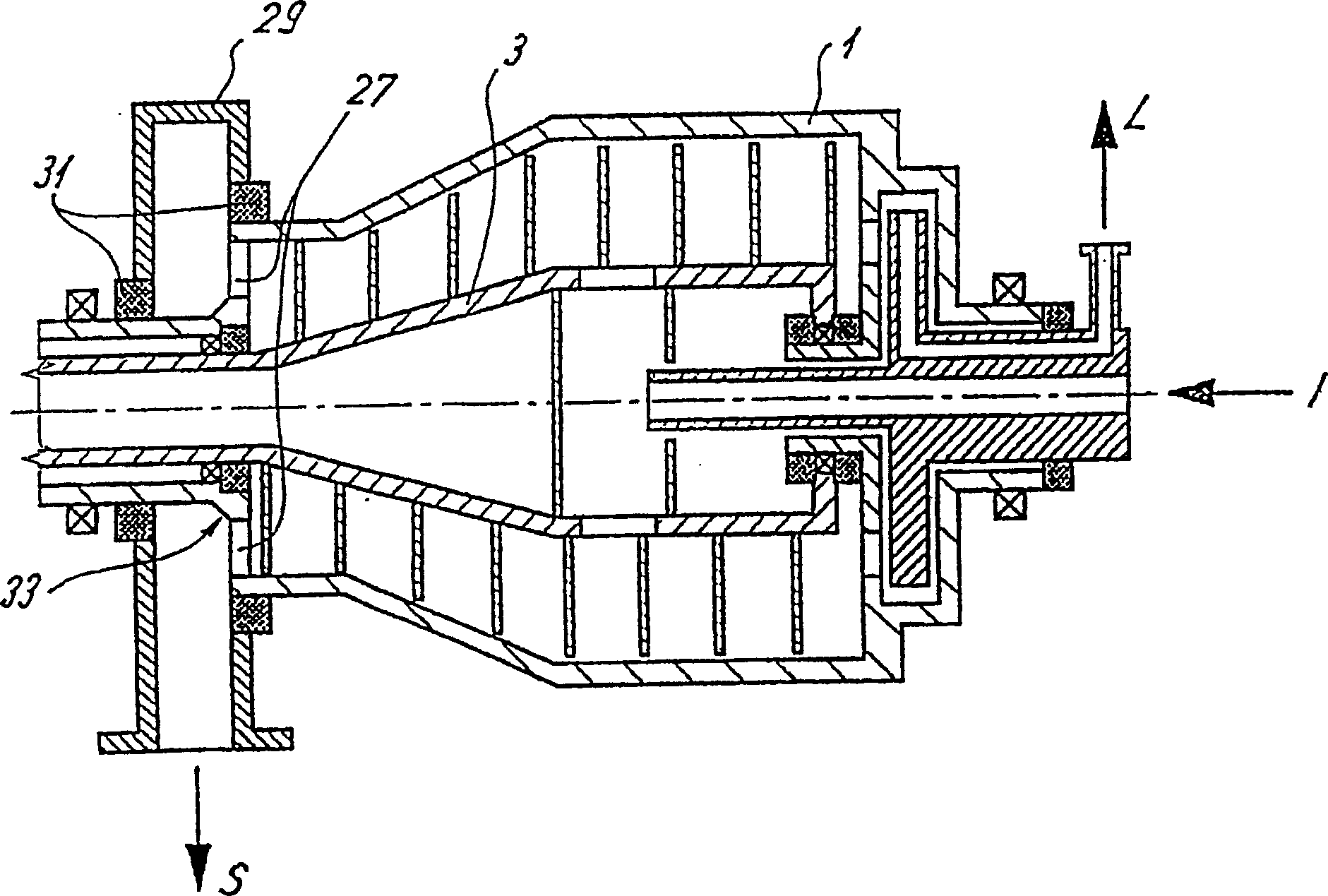

[0030] figure 1 Shown is a non-perforated drum screw conveying centrifuge with a drum 1 and a helical rotor 3 inside the drum 1 with a helical rotor body 5 and a helical plate wound on the body 5 in the form of a helix 7. The channel 11 for conveying the material to be centrifuged is located between the spirals 9a, 9b, . . . A bearing 4 and a sealing ring 6 are arranged between the drum 1 and the screw rotor body 5 at both ends of the non-porous drum screw conveying centrifuge.

[0031] exist figure 1 In the rear region, the centrifuge bowl has a cylindrical portion 13 and in its front region has a conical portion 15 adjacent to the cylindrical portion 13 (or graded). The drum also has a further cylindrical portion 17 axially adjoining the conical portion 15, to which a head 18 of the drum (and / or a hub) is connected.

[0032] The centrifuged material I enters the distributor 21 through the centrally arranged inlet pipe 19, and from there enters the centrifugal space 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com