Sealed device for drive-shaft

A technology of sealing device and transmission shaft, which is applied in the direction of propulsion transmission device, engine seal, transmission device with synchronous propulsion parts, etc. It can solve the problems of not knowing and not being able to align the transmission shaft well, and achieve optimal pressure discharge effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

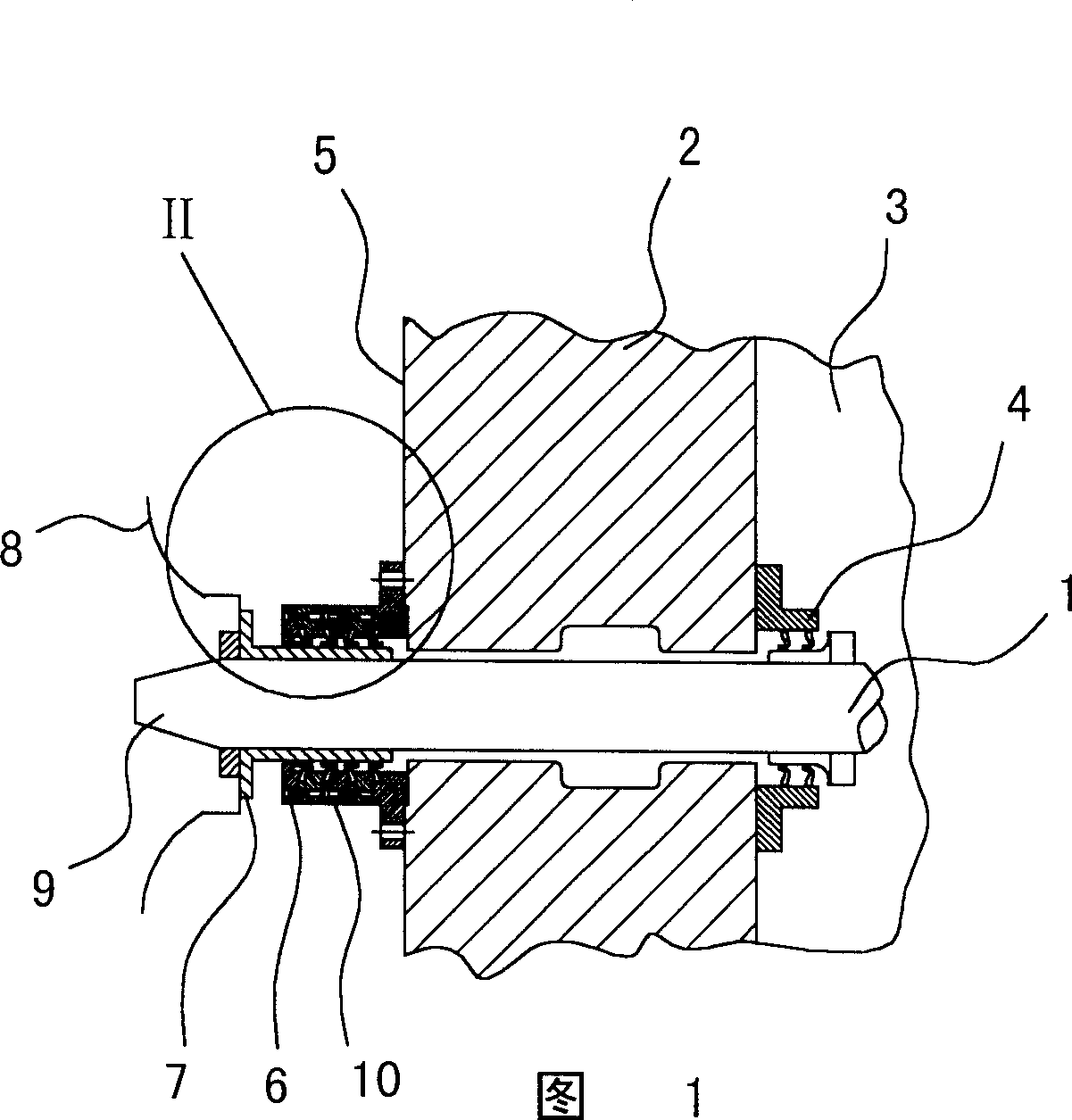

[0030] According to the embodiment shown in FIG. 1 , a drive shaft 1 passes through a ship's outer wall 2 . In the area of a ship interior 3 , a clamping sleeve 4 guides the drive shaft 1 in a sealing manner. Arranged on the outer side 5 of the ship's outer wall 2 is an outer bushing 6 which is fixedly joined to the ship's outer wall.

[0031] An inner shaft sleeve 7 is enclosed within the outer shaft sleeve 6, and it is clamped on the propeller 8 of the ship. The inner shaft sleeve 7 is contained on the outer sector 9 of the transmission shaft 1, which passes through the outer wall 2 of the ship to its outside.

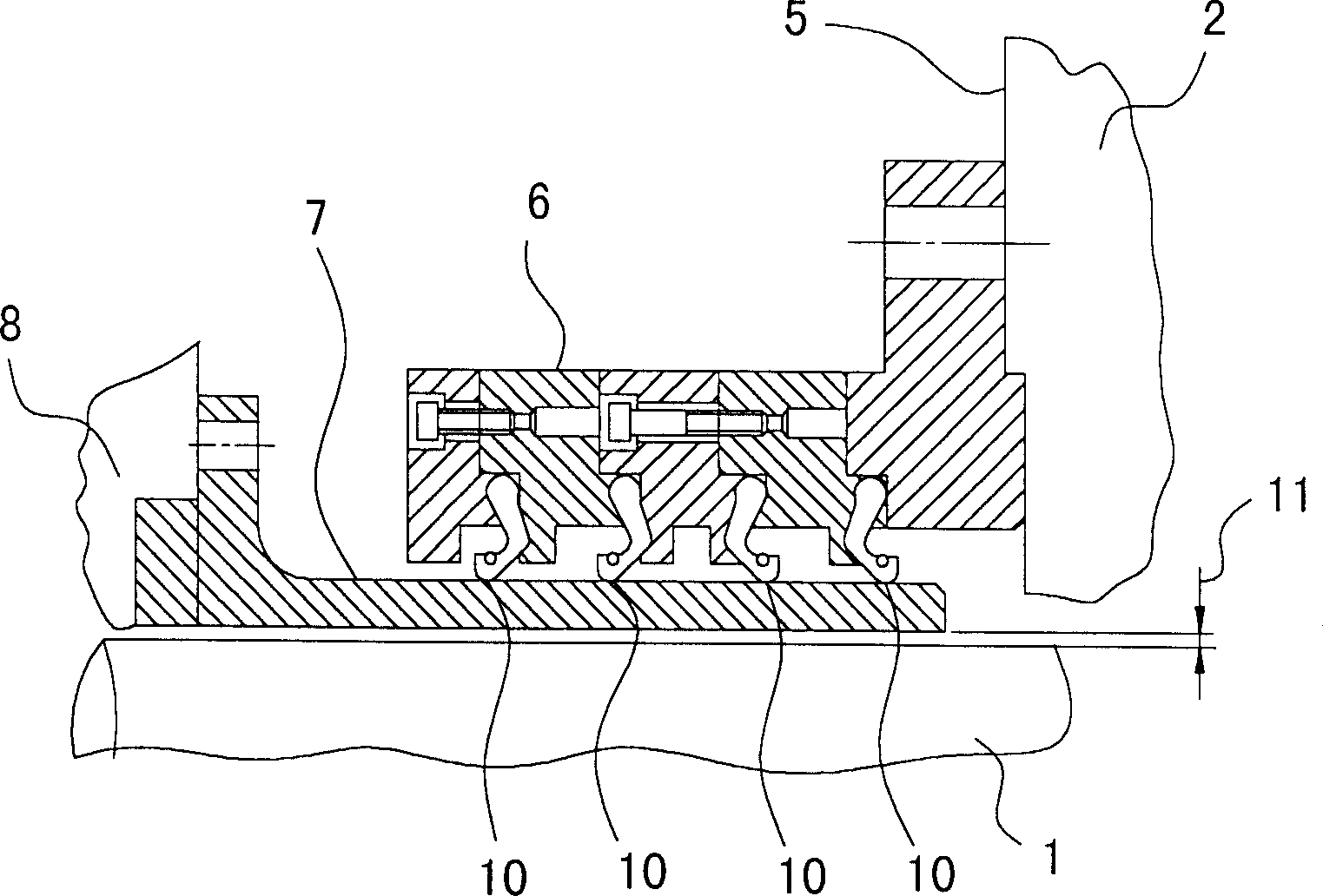

[0032] figure 2 It is an enlarged schematic diagram of various parts of the II part in Fig. 1 . It can be seen from the figure that the outer sleeve 6 clamps a plurality of sealing elements 10 which tightly press the inner sleeve 7 . In this way a good sealing effect is achieved between the inner bushing 7 which rotates with the transmission shaft 1 and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com