Box frame assembly

A box-shaped frame and frame technology, which is applied to display shelves, display hangers, building components, etc., can solve the problems of unattractive frames and increase manufacturing costs, reduce manufacturing costs and material costs, and simplify assembly and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

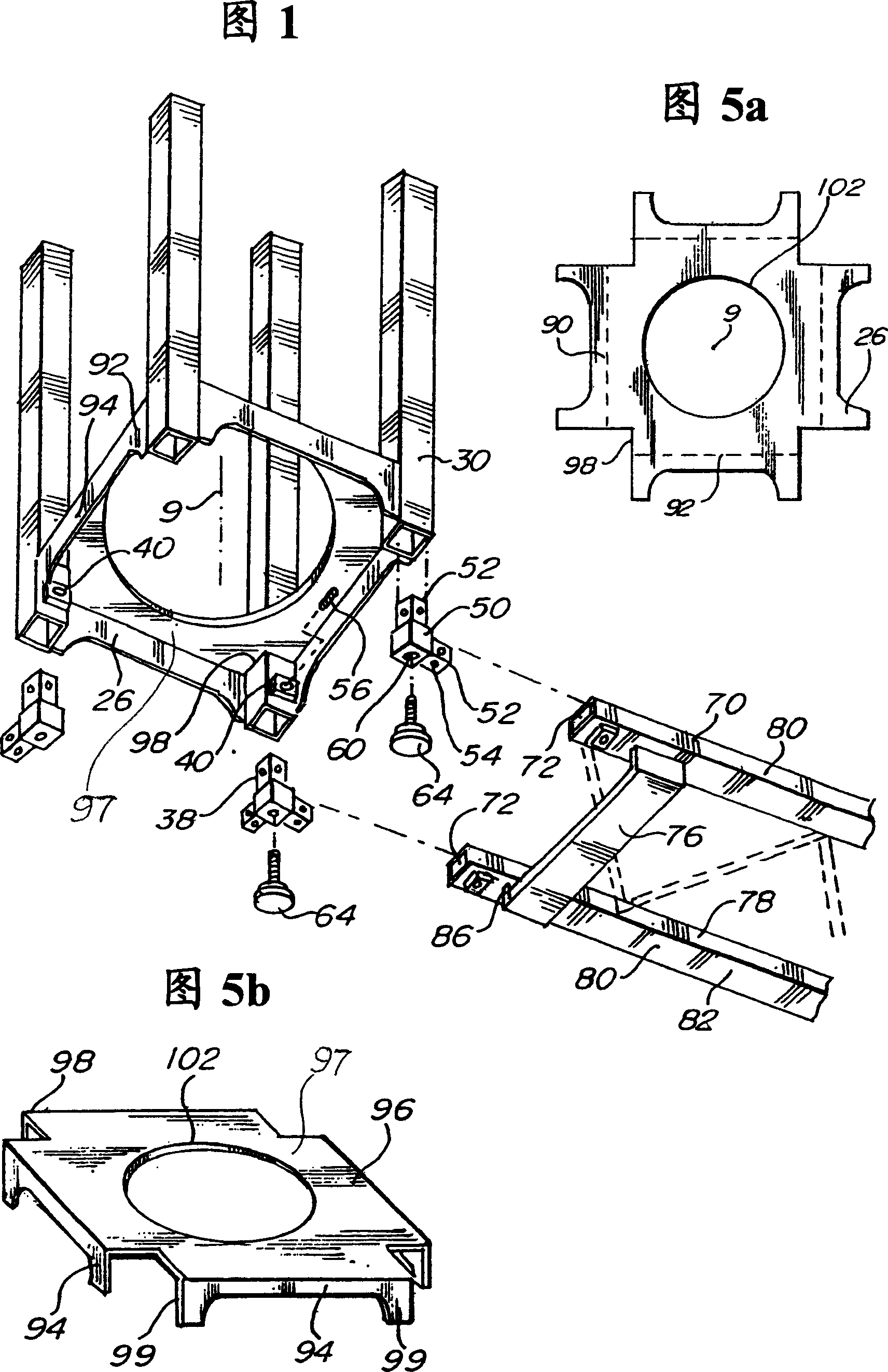

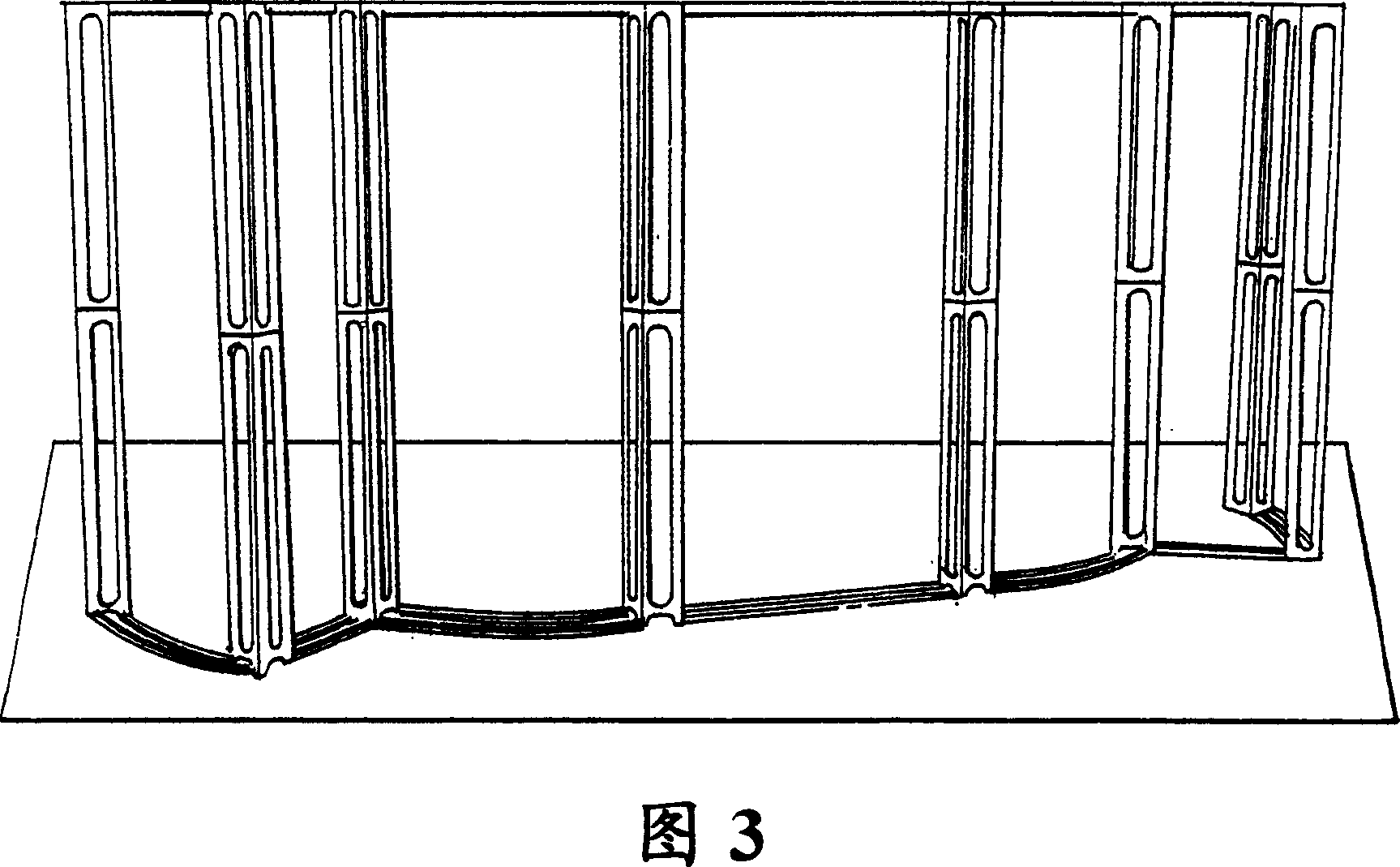

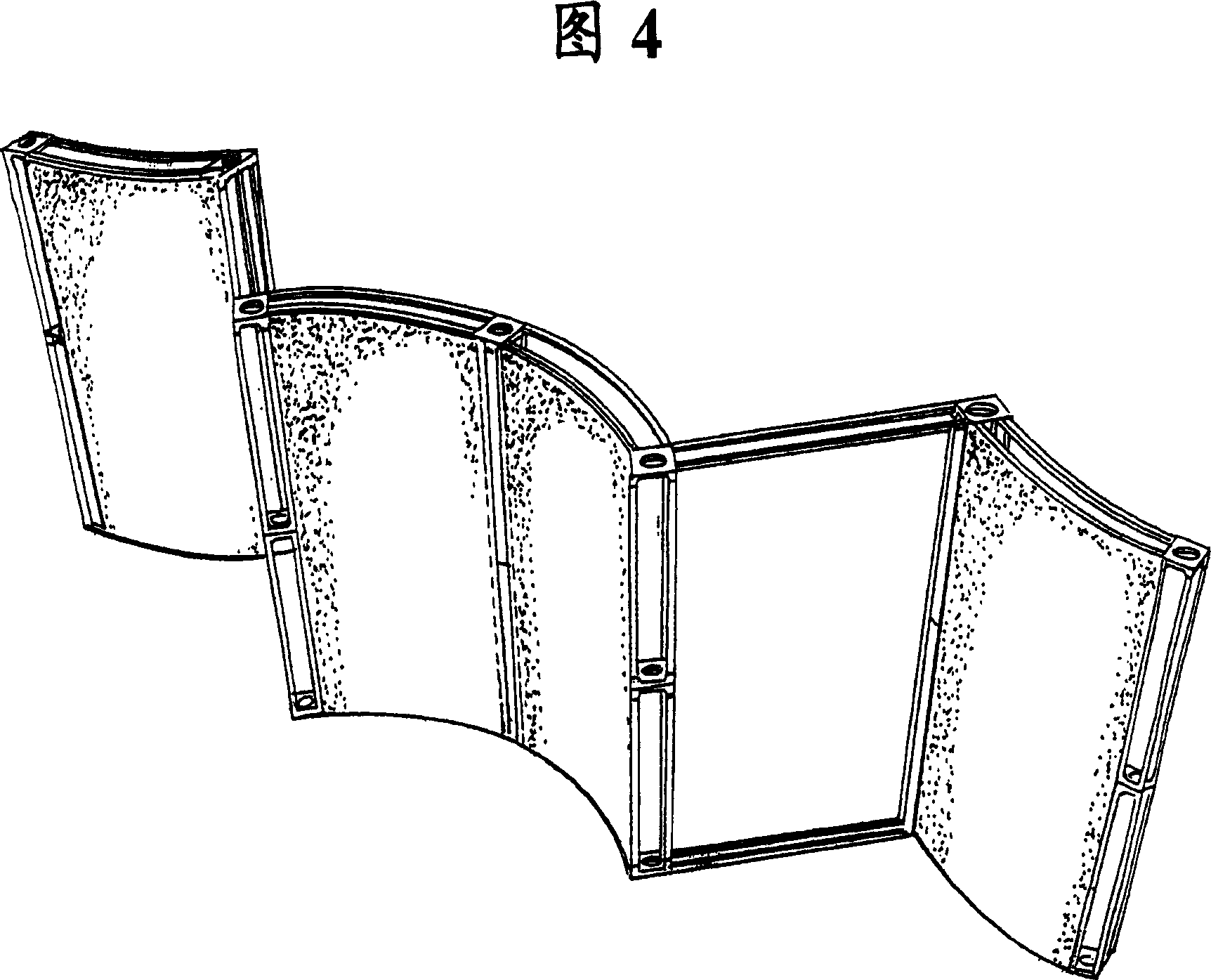

[0026] Embodiments of the present invention will be described below with reference to FIGS. 1 , 2 , 3 and 4 . Referring specifically to FIG. 2 , there is shown an elongated box frame 20 generally comprising four equally sized frame members 22 and a pair of end web members 26 . Each frame member has a first end 27 and a second end 28 . In this embodiment, the frame members extend onto the first end 30 and the second end 31 of the box frame. Each end of the elongated box-shaped frame has a connection portion 32 configured as a socket which is open to receive a male connection portion or connector 38 as shown in FIG. 1 . A threaded portion 40 configured as a nut is welded to an end 44 of the respective frame part 22 .

[0027] The connector 38 generally includes a central body portion 50 and an arrow-shaped connecting portion 52 having a recess 54 for assisting in the positioning of a set screw 56 . Screw holes 60 may be utilized to attach threaded feet 64 or other accessory a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com