Cutting machine for organic plant materials, especially for tobacco

A technology for cutting equipment and plant materials, applied in application, food science, metal processing, etc., can solve the problems of parts that can only be carried out on one side and difficult to maintain, and achieve the effect of simple repair and maintenance and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

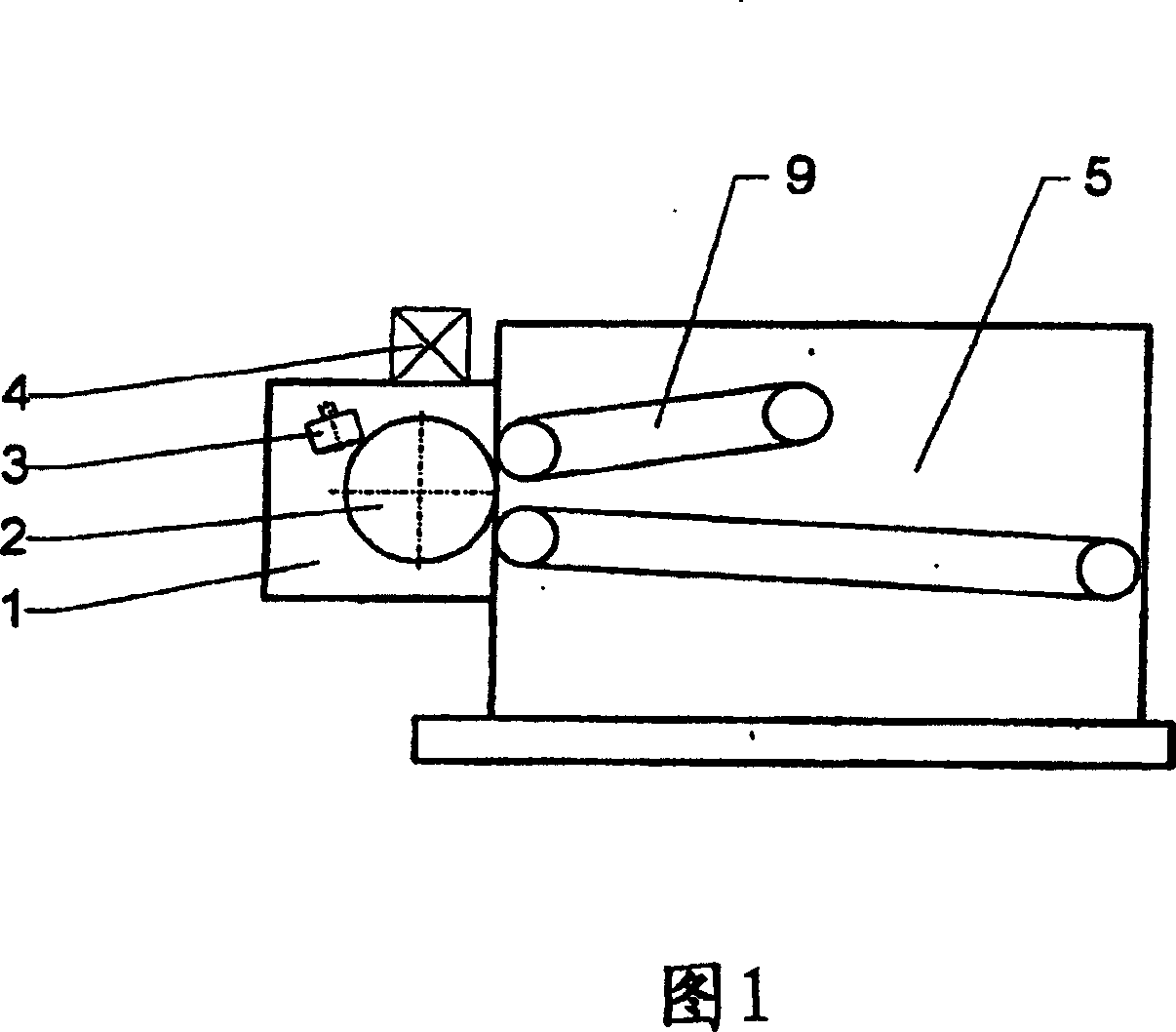

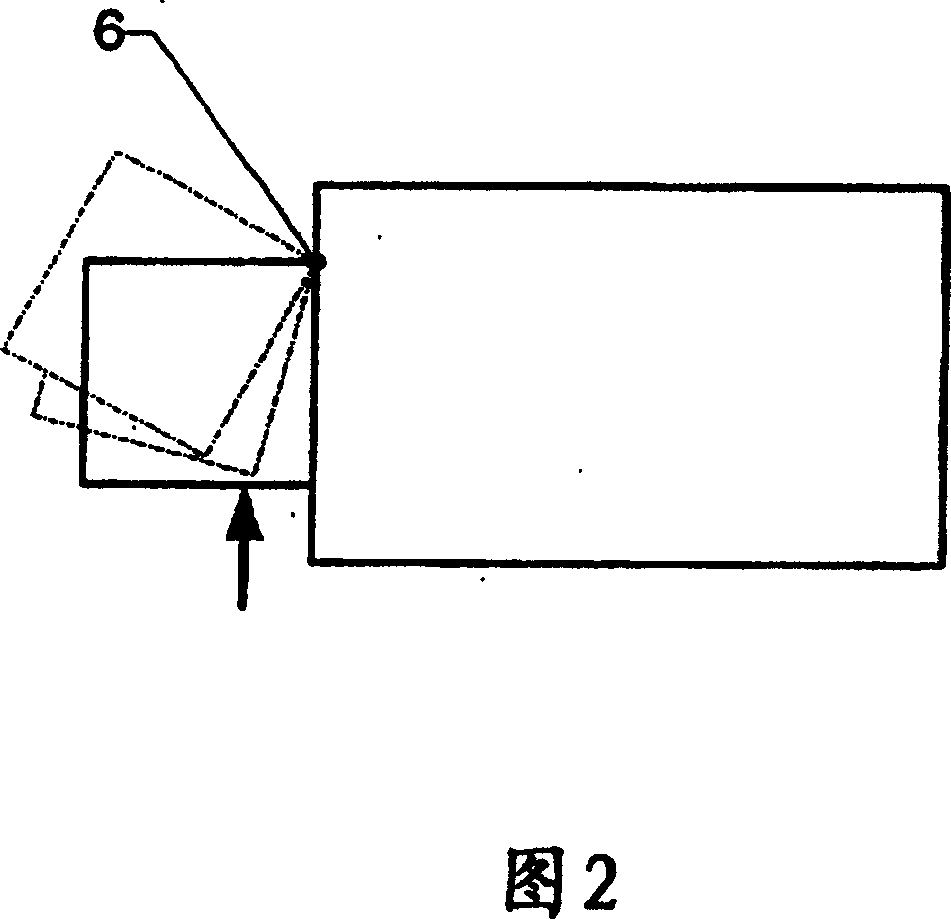

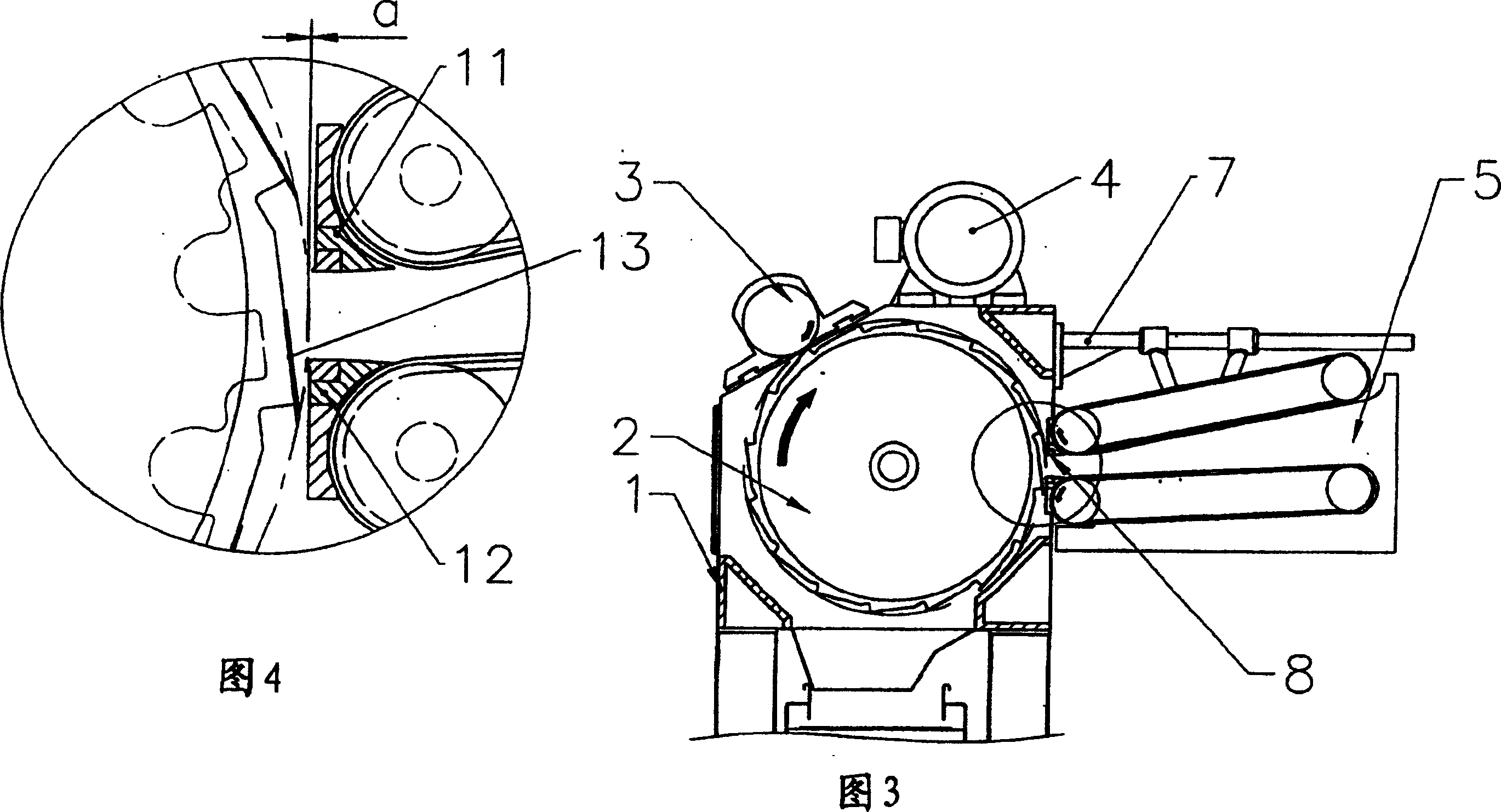

[0029] In the proposed technical solution, the cutting device comprises a chopper 2, which is a chopper mounted on a fixed main frame 1 (Fig. 3), which is fixed to the base plate and rotates in the frame around its horizontal axis ; and the frame 5 of the supply-compacting device, which is not permanently fixed to the main frame 1 . The rotation of the chopper 2 is driven by an electric motor 4 . The feed-compacting plant frame 5 forming the feed material flow comprises conveying means 9 for feeding material to the cutting zone 8, and means for compacting and / or polarizing the relative distribution of said raw material particles. The feeding-compacting device frame 5 is a movable / adjustable frame that slides by guides 7 preferably provided on the frame 5 to create the inlet space P. As shown in FIG.

[0030] During the operation of the device and during its technical, service and / or maintenance operations, the main frame 1 of the chopper 2 remains fixed (immobile with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com